If metal breaks too soon under stress, it could collapse a building, crash a plane, or snap a vital part in your machine.

Tensile strength tells us how much force a metal can withstand before pulling apart. It's a critical measure of a metal's performance under stretching or tension.

You can’t design safe or reliable products without knowing this one number. It affects everything from bridges to bicycles to bolts.

How Is Metal Tensile Strength Measured?

You can’t just guess a metal’s strength by its color or weight. You need numbers, and that means testing.

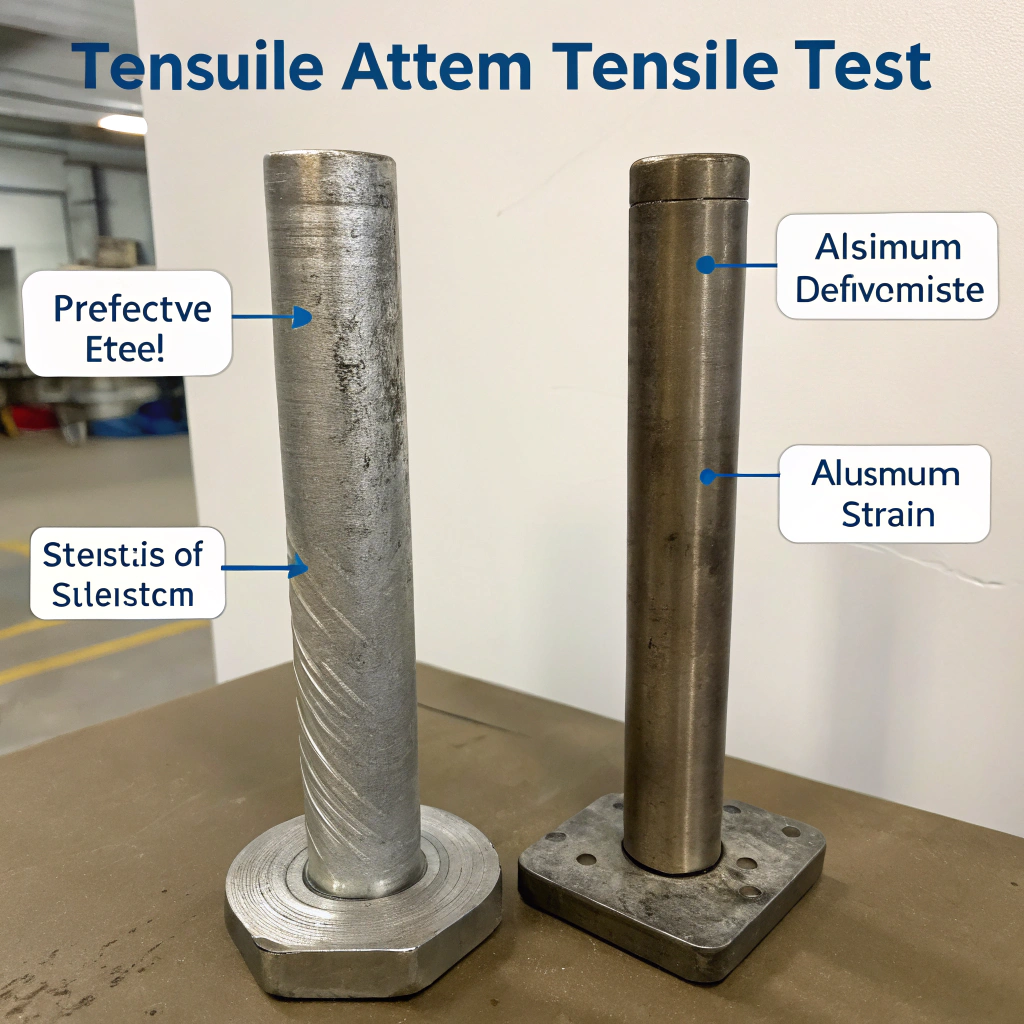

Tensile strength is measured using a tensile test. A sample is pulled apart by a machine until it breaks. The maximum stress it handles is the tensile strength.

The Test Process

-

Prepare the Sample

The metal is shaped into a standard dog-bone sample. -

Mount in Testing Machine

The sample is clamped at both ends. -

Apply Force

The machine pulls steadily until the sample breaks. -

Record Data

It tracks force (in Newtons) and extension (in mm).

Key Outputs

- Ultimate Tensile Strength (UTS): Maximum stress before breaking

- Yield Strength: Stress where permanent deformation begins

- Elongation: How much it stretched before breaking

Here’s a simple table to show what a tensile test might reveal:

| Property | Steel (Typical) | Aluminum (Typical) |

|---|---|---|

| Yield Strength (MPa) | 250–550 | 35–400 |

| Tensile Strength (MPa) | 370–1800 | 90–570 |

| Elongation (%) | 10–25 | 10–20 |

The exact numbers depend on the alloy and how it was processed.

Standards Used

- ASTM E8/E8M for metals in the US

- ISO 6892 for international testing

- GB/T 228 in China

Following the right standard makes sure the results are trusted across industries and borders.

Why Does Tensile Strength Matter in Construction?

Buildings must stand for decades. Bridges must hold up thousands of vehicles. Metal failure isn’t just expensive — it’s dangerous.

Tensile strength matters in construction because it ensures metal parts won’t stretch, deform, or snap under load. It protects structures from failure under stress.

Load-Bearing Applications

Steel beams, rebar, fasteners, and support cables all carry tension. If they stretch too far or break, buildings crack, walls tilt, or roofs sag.

For example, tension cables in suspension bridges need high tensile strength to keep the bridge stable. If these cables snap, the entire structure can fail.

Earthquake and Wind Resistance

In places with natural forces like earthquakes or hurricanes, tensile strength becomes critical. A high-tensile steel frame can flex without breaking, absorbing energy and keeping the structure standing.

Choosing the Right Steel Grade

Construction engineers pick steel based on tensile strength ratings. For example:

| Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Use Case |

|---|---|---|---|

| Q235 | 235 | 375–460 | General structure |

| Q345 | 345 | 470–630 | Bridges, heavy load buildings |

| Q690 | 690 | 770–940 | High-strength applications |

Without this data, designing safe buildings would be impossible.

How to Apply Metal Strength Data in Design?

Having test results is not enough. You must apply them. If you don’t, your design might look good — but collapse under stress.

You apply tensile strength data by comparing it to the actual forces your design will face. This helps choose suitable materials, safety factors, and part thicknesses.

Step 1: Analyze the Load

Every part in a design will carry some load — tension, compression, shear, or bending. Figure out the forces it will experience during normal and extreme conditions.

Step 2: Use Safety Factors

Real-world conditions are never perfect. So, designers multiply the expected load by a safety factor (usually 1.5 to 3) to ensure the metal holds up under uncertainty.

If a bolt is expected to hold 10 kN, and you use a safety factor of 2, then choose a metal that can handle at least 20 kN in tension.

Step 3: Match to Material Properties

Using a material data sheet, check the tensile strength, yield strength, and elongation. Compare it to your required load capacity.

Step 4: Simulate the Design

Use Finite Element Analysis (FEA) tools to test your design virtually. These tools show stress points, areas at risk of failure, and whether your chosen metal is strong enough.

Practical Example

Designing a mounting bracket for a machine:

- Expected tension: 50 MPa

- Chosen steel: Yield = 250 MPa, UTS = 370 MPa

- Safety factor = 2

The design load is well below the yield point, even with safety applied. This means the bracket won’t deform or break in use.

What Are Future Developments in Metal Strength Research?

Science is not done with metal. Every year, new alloys and testing methods push performance higher and costs lower.

Future developments focus on high-entropy alloys, nanostructured metals, and AI-driven material design. These innovations promise stronger, lighter, and smarter metals.

High-Entropy Alloys (HEAs)

These are made by mixing five or more elements in near-equal ratios. Their atomic randomness gives incredible strength, corrosion resistance, and temperature stability.

Research shows some HEAs outperform stainless steel and nickel superalloys in toughness and strength.

Nanostructured Metals

When you shrink the grains in a metal to the nanometer scale, it becomes much stronger. These materials are already used in aerospace and defense but are expanding into commercial use.

Additive Manufacturing (3D Printing)

New metal printing methods allow precise control over microstructure. Designers can print parts with graded strength, optimized for stress distribution.

AI and Machine Learning in Metallurgy

AI models can now predict the best alloy composition for a desired strength level. This saves time and reduces waste in the development of new materials.

Smart Materials

Metals are being developed that change strength based on temperature or magnetic fields. This opens new possibilities for adaptive structures in vehicles and robotics.

Conclusion

Tensile strength is more than a number — it’s the foundation of safe, efficient, and long-lasting metal design. Whether you're building a tower, a turbine, or a tool, understanding and applying tensile strength ensures your project stands the test of time.