When traditional cutting methods fail to meet the demand for precision, we rely on a method that doesn't even touch the material: wire EDM cutting.

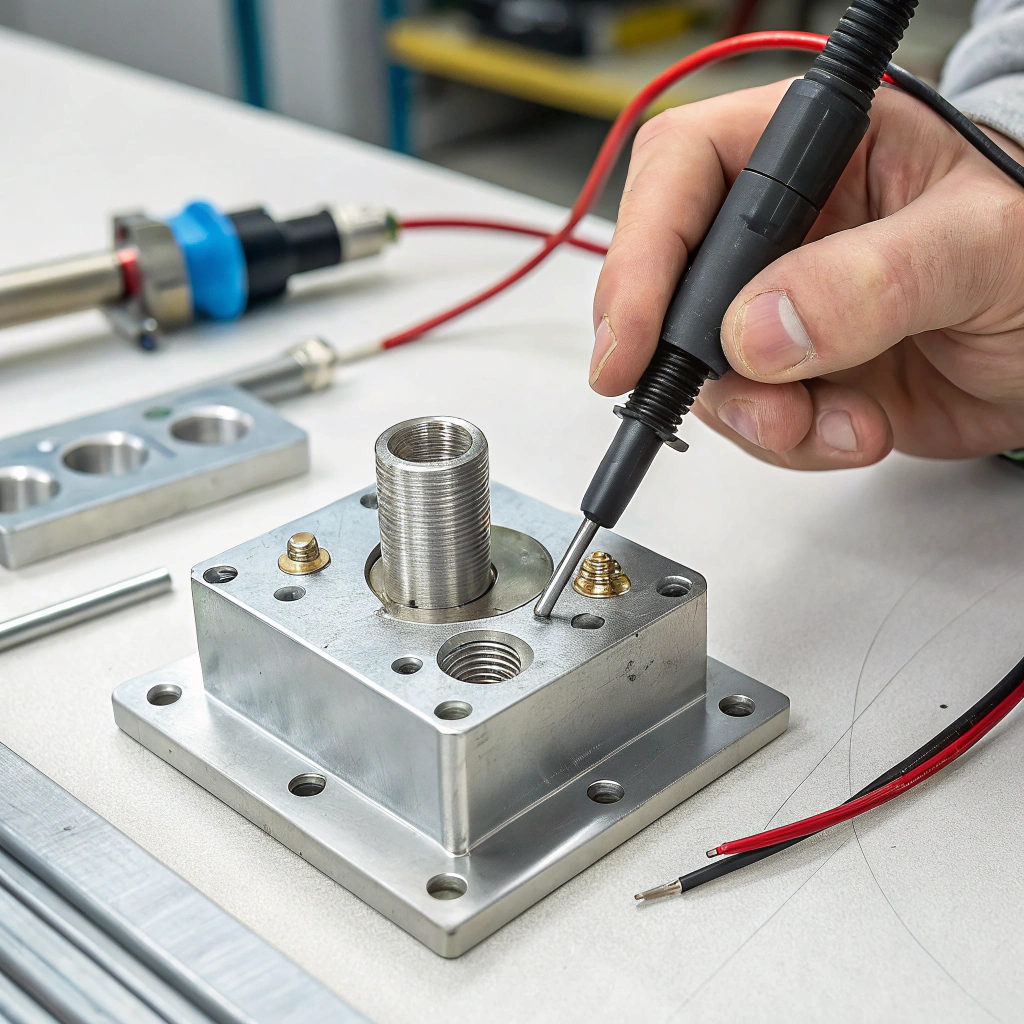

Wire EDM (Electrical Discharge Machining) uses a thin, electrically charged wire to erode conductive materials through rapid, controlled sparks, enabling extremely precise and complex cuts.

This process allows me to shape hard metals without applying force or heat directly. It’s ideal for applications needing high accuracy and fine detail, especially in the tool and die, aerospace, and medical sectors.

Why Is Wire EDM Cutting Valuable for Precision Work?

Precision manufacturing often pushes the limits of what standard tools can handle. We need methods that work beyond those boundaries.

Wire EDM cutting provides superior accuracy, handles extremely hard materials, leaves no mechanical stress, and produces smooth, burr-free edges.

Benefits of Wire EDM in Precision Manufacturing

| Feature | Advantage |

|---|---|

| Tight Tolerances | Achieves tolerances as close as ±0.002 mm |

| No Tool Pressure | Ideal for delicate or thin components |

| Works on Hard Metals | Easily cuts hardened steels, titanium, and tungsten |

| Intricate Geometry | Capable of complex shapes and sharp internal corners |

| Burr-Free Finish | No need for secondary deburring |

Traditional cutting tools may fail or deform hard parts. EDM uses spark erosion, meaning there’s no contact and virtually no distortion. That gives me the ability to create precision components that meet even the most demanding specs.

How to Use Wire EDM Cutting Effectively?

It’s not just about owning the equipment — effective use of wire EDM means controlling every part of the process with discipline and precision.

To use wire EDM effectively, I prepare the part properly, choose the right wire and fluid, carefully program the cut path, and control spark settings for smooth, accurate results.

Essential Steps in the Wire EDM Process

-

Part Preparation

- Material must be conductive (steel, aluminum, etc.)

- Surface should be clean and mounted securely

-

Wire Selection

- Brass or coated wire, usually 0.10–0.30 mm in diameter

- Finer wires allow finer details but are slower

-

Dielectric Fluid Setup

- Deionized water is standard

- It removes debris and cools the part

-

Program the Cut

- CAD software generates the toolpath

- Parameters include spark rate, wire feed speed, and flushing pressure

-

Monitoring

- Watch for wire breaks, spark stability, and debris buildup

- Adjust fluid flow and tension if needed

Key Design Considerations

| Aspect | Best Practice |

|---|---|

| Corner Radii | Use small arcs to avoid wire overshoot |

| Part Thickness | Consider flushing efficiency on deep cuts |

| Kerf Width | Allow for 0.1–0.3 mm overcut from spark gap |

| Recast Layer | Consider finish passes to reduce affected zones |

If I ignore these factors, even the best EDM setup will produce imperfect parts. But by mastering them, I ensure that every part comes off the machine clean and ready to go.

What Are the Latest Innovations in Wire EDM Cutting?

Wire EDM has been around for decades, but today’s machines are more advanced than ever. The new tech makes it faster, smarter, and even more precise.

Recent innovations in wire EDM include ultra-fine wires, automated threading, adaptive spark control, real-time monitoring, and improved material compatibility.

What’s New in Wire EDM?

1. Ultra-Fine Wire Technology

Some modern machines can use wires as thin as 0.02 mm. This makes it possible to produce micro-components in electronics or medical devices.

2. Smart Automation

Wire threading systems now re-feed the wire automatically after a break. Machines also auto-adjust settings based on part geometry.

3. High-Speed Roughing Modes

New pulse generators allow faster material removal while maintaining accuracy. That means shorter cycle times on production parts.

4. Rotary and 5-Axis Motion

Multi-axis machines allow angled cuts, tapered walls, and even 3D contours — something I couldn’t do with older 2-axis setups.

5. Cleaner, Eco-Friendly Operation

Some systems now recycle dielectric fluids, use lower energy pulses, and have better enclosures for environmental control.

Comparing Traditional and Modern Wire EDM

| Feature | Traditional EDM | Modern EDM |

|---|---|---|

| Wire Change | Manual | Automatic threading |

| Spark Control | Fixed settings | Adaptive, real-time adjustment |

| Cut Geometry | 2-axis only | 4- or 5-axis cutting |

| Speed | Slower rough cuts | High-speed roughing + finish passes |

| Maintenance | Manual monitoring | Predictive diagnostics |

With these upgrades, I can produce more parts faster, with better finishes, less downtime, and more reliable performance — all of which are critical for B2B manufacturing.

Conclusion

Wire EDM cutting is one of the most precise and versatile machining methods available. It’s perfect for cutting hard metals, complex shapes, and tight tolerances with no mechanical force. By mastering setup, programming, and process control — and keeping up with the latest technology — I can deliver superior results and meet the high demands of modern manufacturing.