Titanium CNC machining has become an essential technique for producing high-precision parts in industries like aerospace, medical devices, and automotive. With its strength and resistance to corrosion, titanium is a preferred material, but it requires special handling during the machining process.

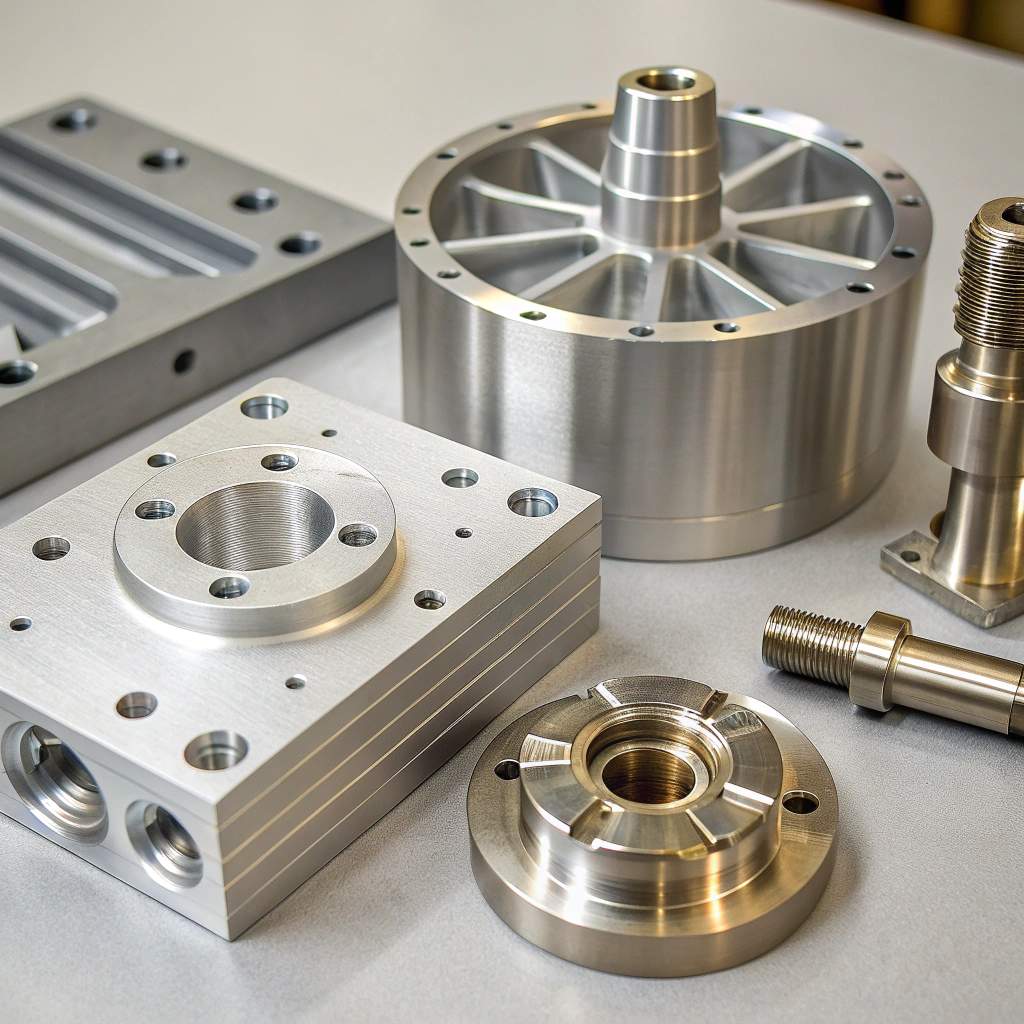

Titanium CNC machining refers to the process of shaping titanium using computer-controlled tools to create highly accurate and durable parts. These parts are used in critical applications where both strength and lightweight properties are required.

Titanium is a challenging material to work with. Its hardness and tendency to work-harden make it difficult for traditional machining methods. However, with CNC technology, we can achieve precise results while overcoming the challenges titanium presents.

What are the Benefits of Titanium CNC Machining?

Titanium is known for its remarkable properties like corrosion resistance, high strength-to-weight ratio, and biocompatibility, making it ideal for use in demanding environments. But what benefits does CNC machining bring to the table when working with titanium?

CNC machining allows for precise and repeatable production of titanium parts, making it perfect for industries that require high-quality components. The use of CNC machines ensures that each part is consistent and made to exact specifications. But there’s more—let's dive into the key advantages.

Precision and Accuracy

One of the most significant advantages of using CNC machining for titanium is precision. CNC machines use automated processes that remove material in highly controlled ways, ensuring that parts are manufactured to exact dimensions. This is crucial for industries like aerospace, where even the slightest error can lead to catastrophic failure.

Complex Designs Made Easy

Titanium parts are often complex, with intricate shapes and tight tolerances. CNC machines can handle these complex designs with ease, creating parts that would otherwise be difficult to produce using traditional machining methods. This ability opens up new possibilities for design in industries such as medical implants, where precise geometries are crucial.

Improved Surface Finish

Titanium has a tendency to create a rough surface when machined. However, CNC machining allows for smoother finishes, which is important for components used in fields like medical or aerospace. The ability to create clean, polished surfaces also improves the performance and longevity of the parts.

Material Efficiency

Titanium is expensive, so reducing waste during production is important. CNC machining is highly efficient, removing only the necessary amount of material to create the final part. This is especially beneficial when working with high-cost materials like titanium, as it helps reduce production costs.

Cost-Effective Production

While CNC machining can have higher upfront costs for the machinery, it offers significant cost savings over time. The ability to automate the process and produce high-precision parts reduces the need for manual labor and rework, making it more cost-effective in the long run.

How to Perform Titanium CNC Machining Effectively?

Machining titanium is not without its challenges. The metal’s hardness, tendency to heat up quickly, and the risk of work-hardening require special consideration. Let’s look at how to perform titanium CNC machining effectively and avoid common pitfalls.

When machining titanium, selecting the right tools, cutting parameters, and machining strategies is critical to ensure success. This means using the correct tools, applying the right cutting speeds, and ensuring that the machine setup is ideal for titanium’s unique properties.

Choosing the Right Tooling

When machining titanium, the first step is to select the right tools. Titanium is a hard and dense material, so using the wrong tool can result in rapid wear and poor results. Carbide tools are often the preferred choice for titanium machining because of their ability to withstand the material's toughness.

In addition to carbide tools, coatings like TiN (Titanium Nitride) are frequently used to reduce friction and extend tool life. The coating protects the tool from heat build-up, a major concern when machining titanium.

Optimizing Cutting Parameters

Cutting speed, feed rate, and cutting depth are all critical parameters when machining titanium. Typically, cutting speed should be lower than for other metals to prevent overheating and tool wear. A higher feed rate, however, is recommended to avoid excessive heat buildup and improve the cutting efficiency.

Here is a quick guide to help you choose the right cutting parameters for titanium:

| Cutting Parameter | Recommended Value |

|---|---|

| Cutting Speed | 30–80 m/min (depending on the alloy) |

| Feed Rate | 0.1–0.3 mm/tooth |

| Depth of Cut | Shallow cuts to reduce stress |

Additionally, using a coolant or lubricant is essential for controlling heat and extending tool life. High-pressure coolant systems can be particularly effective for titanium machining, as they help manage the heat generated during the cutting process.

Preventing Work Hardening

Titanium is prone to work hardening, which occurs when the surface layer of the material becomes harder as it’s subjected to heat and pressure. To prevent work hardening, ensure that the cutting tool is sharp and the feed rate is consistent. Avoid dwelling on any area of the part for too long, as this can cause localized hardening.

What Are the Advancements in Titanium CNC Machining?

Titanium CNC machining has come a long way. The latest advancements in technology have significantly improved machining processes, tool life, and production speed. Let’s explore some of the most notable advancements.

Technological advancements in CNC machining are enabling manufacturers to work with titanium more efficiently and at a lower cost. From improved tools to new machining strategies, these innovations are transforming the industry.

High-Energy Laser Cutting

Laser cutting technology has revolutionized how titanium is processed. Laser cutting is a non-contact process that uses a high-powered laser beam to cut titanium with extreme precision. This process produces less mechanical stress on the material, which helps maintain its integrity. Laser cutting is also faster compared to traditional methods, making it ideal for high-volume production.

Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, has opened up new possibilities for working with titanium. 3D printing allows for the creation of highly complex parts that would be difficult or impossible to make using traditional machining methods. In some cases, 3D printing is combined with CNC machining to produce parts that are both intricate and precise.

Hybrid Machining

Hybrid machining is another breakthrough that combines both additive and subtractive manufacturing. With hybrid machines, manufacturers can build up layers of titanium using additive manufacturing and then machine the part to its final shape. This approach can significantly reduce production time and material waste, making it a more efficient process for creating complex titanium parts.

Automation and AI Integration

Automation in CNC machining is becoming increasingly common, with robots and AI systems helping to streamline operations. Automation allows for faster setups, quicker tool changes, and improved consistency in production. AI algorithms can also optimize cutting parameters in real-time, further improving efficiency and reducing human error.

Enhanced Tool Coatings and Materials

New developments in tool coatings have increased the lifespan of tools used in titanium machining. Coatings like TiAlN (Titanium Aluminum Nitride) help reduce wear and friction, allowing tools to maintain sharpness longer and perform better during high-temperature machining. These coatings are especially important when working with titanium, as the material tends to heat up quickly during machining.

Conclusion

In conclusion, titanium CNC machining is essential for creating high-precision parts used in demanding industries. The benefits of using CNC machines for titanium include high accuracy, the ability to create complex geometries, and efficient material use. With advancements like laser cutting, additive manufacturing, and improved tool coatings, titanium machining is becoming faster and more cost-effective.