Titanium anodizing is an electrochemical process used to increase the natural oxide layer on the surface of titanium metal. This oxide layer not only enhances the material's corrosion resistance but also provides the opportunity to create vibrant, durable colors through interference effects. Anodizing titanium is commonly used in a wide range of industries, including aerospace, medical devices, and consumer goods.

Titanium anodizing involves immersing the titanium part in an electrolytic solution and applying a voltage to it. This process creates a thick oxide layer on the titanium surface, which can be customized in thickness depending on the intended purpose. This anodized layer significantly improves the metal's properties, making it more durable and aesthetically appealing.

Anodized titanium is commonly used for decorative purposes, in addition to providing protection against corrosion and wear. It is also utilized for its electrical insulation properties in certain applications.

What Are the Benefits of Titanium Anodizing?

Titanium anodizing offers a wide range of benefits that make it one of the most popular surface treatment methods for titanium. From improving the material's durability to adding aesthetic appeal, anodizing enhances titanium’s overall performance.

Titanium anodizing provides both functional and aesthetic advantages, including improved corrosion resistance, enhanced wear properties, and a wide range of vibrant color options. Here are some of the most notable benefits of anodizing titanium.

Enhanced Corrosion Resistance

One of the most significant benefits of titanium anodizing is its ability to improve the material's resistance to corrosion. Titanium, in its raw form, is already highly resistant to corrosion, but anodizing further enhances this property by creating a thicker, more protective oxide layer. This makes anodized titanium an ideal choice for harsh environments such as marine or chemical industries.

Increased Wear Resistance

The anodized layer on titanium also increases its resistance to wear and abrasion. The oxide layer acts as a protective barrier that helps reduce surface damage caused by friction and mechanical wear. This makes anodized titanium an excellent choice for components subjected to high wear, such as medical implants, automotive parts, and aerospace components.

Aesthetic Appeal and Color Options

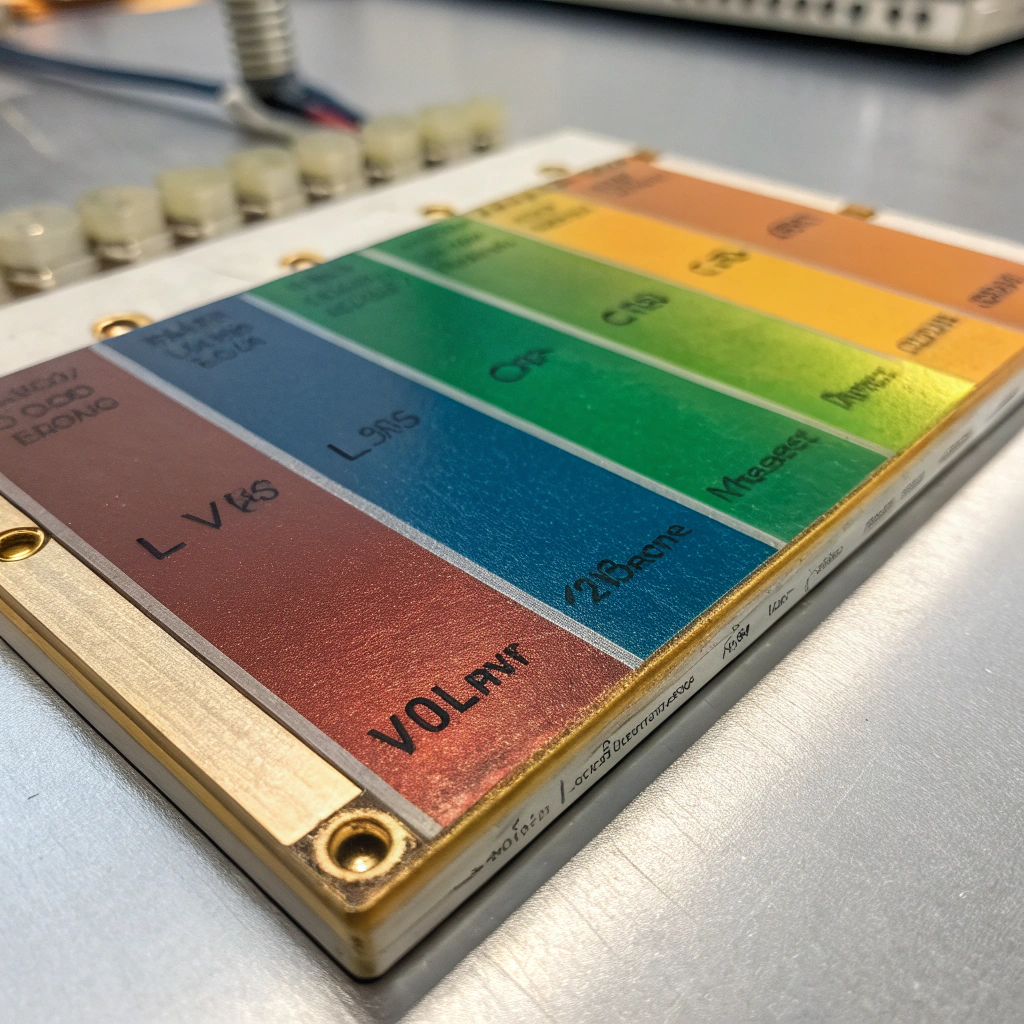

Anodizing titanium can produce a wide array of vibrant colors, including gold, blue, purple, and rainbow effects. These colors are a result of the interference effect of light on the oxide layer. This aesthetic benefit makes anodized titanium an attractive choice for decorative purposes, such as jewelry, watch components, and high-end consumer products.

Electrical Insulation

Another key benefit of anodizing titanium is its ability to provide electrical insulation. The oxide layer created during the anodizing process is a poor conductor of electricity, which can be beneficial in applications where electrical insulation is needed. This makes anodized titanium ideal for use in electrical components, sensors, and other electronic devices.

Environmental Resistance

Anodized titanium is highly resistant to environmental degradation. It is not affected by UV radiation, is immune to many chemicals, and can withstand extreme temperatures. This makes it suitable for a variety of challenging environments, including those found in the aerospace and marine industries.

How to Perform Titanium Anodizing Correctly?

Titanium anodizing requires a precise and controlled process to ensure the desired results are achieved. The key to successful anodizing is controlling the voltage, electrolyte composition, and immersion time, as well as using the correct titanium alloy.

To perform titanium anodizing correctly, it is essential to follow a step-by-step process that includes preparation, anodizing, and post-treatment to ensure a high-quality oxide layer. Here is a breakdown of the key steps involved in anodizing titanium.

Step 1: Surface Preparation

Before anodizing, the titanium part must be thoroughly cleaned to remove any dirt, grease, or oxidation. This is typically done by using an alkaline or acidic cleaning solution, followed by rinsing the part in distilled water. The cleaner the titanium surface, the better the anodizing results will be.

Step 2: Setting Up the Anodizing Bath

The anodizing bath consists of an electrolytic solution, usually sulfuric acid, but other acids like phosphoric acid or organic acids can also be used depending on the desired outcome. The titanium part serves as the anode in the electrolytic bath, while the cathode is typically made of lead, stainless steel, or a similar conductive material.

The voltage applied to the bath is crucial in determining the thickness and properties of the oxide layer. For example, a higher voltage creates a thicker oxide layer, which may lead to stronger corrosion resistance but can also affect the color of the anodized surface.

Step 3: Anodizing the Titanium

Once the part is in the anodizing bath, a direct current (DC) voltage is applied. The voltage is typically in the range of 10-100 volts, but it can vary depending on the alloy and the specific characteristics needed. The anodizing process takes place as the titanium surface reacts with the electrolyte to form the oxide layer. The color of the anodized surface is also influenced by the voltage, with different voltage levels creating different interference effects and colors.

Step 4: Rinsing and Drying

After anodizing, the titanium part must be rinsed thoroughly in distilled water to remove any residual acid from the surface. The part is then dried using compressed air or left to air dry. The anodized titanium is now ready for inspection or further processing.

Step 5: Post-Treatment (Optional)

For enhanced durability, the anodized titanium can undergo post-treatment processes, such as sealing. Sealing involves immersing the anodized part in hot distilled water or a sealing solution, which helps to close the pores of the oxide layer, making it more resistant to wear and corrosion.

What Are the Latest Innovations in Anodizing Titanium?

The field of titanium anodizing continues to evolve with the development of new techniques and technologies that enhance the process and open up new possibilities for its applications. From more sustainable practices to enhanced color effects, these innovations are driving the future of titanium anodizing.

The latest innovations in titanium anodizing focus on improving the efficiency, environmental sustainability, and aesthetic effects of the process. Here are some of the key trends shaping the future of titanium anodizing.

Environmentally Friendly Anodizing

Traditional anodizing processes use harsh chemicals, such as sulfuric acid, which can be harmful to the environment. Recent advancements in anodizing technology focus on reducing the environmental impact of the process. Eco-friendly anodizing solutions are being developed that use less toxic chemicals and generate fewer waste products, helping to make the process more sustainable.

Improved Color Control

New anodizing techniques are allowing for more precise control over the color and finish of anodized titanium. Innovations in voltage control, as well as the development of new electrolyte formulations, are enabling manufacturers to achieve even more vibrant, uniform, and customizable colors. This is particularly important for industries where aesthetics are a key consideration, such as jewelry and consumer electronics.

High-Temperature Anodizing

High-temperature anodizing is another innovation that is gaining traction. This process involves anodizing titanium at elevated temperatures, which results in thicker oxide layers that offer even better protection against corrosion and wear. High-temperature anodizing is particularly useful for components that will be exposed to extreme conditions, such as in aerospace or industrial machinery.

Anodizing with Nanotechnology

Nanotechnology is being incorporated into the anodizing process to create even more durable and functional oxide layers. By incorporating nanoscale materials into the anodizing solution or directly onto the titanium surface, manufacturers can enhance the properties of anodized titanium, such as increasing its hardness, wear resistance, or biocompatibility. This has great potential in medical and aerospace applications.

Conclusion

In conclusion, titanium anodizing is a versatile and effective surface treatment that improves the properties and appearance of titanium components. With benefits ranging from enhanced corrosion resistance to vibrant color options, anodizing plays a key role in various industries. As technology advances, innovations in anodizing methods continue to enhance the process, making it more sustainable, efficient, and customizable.