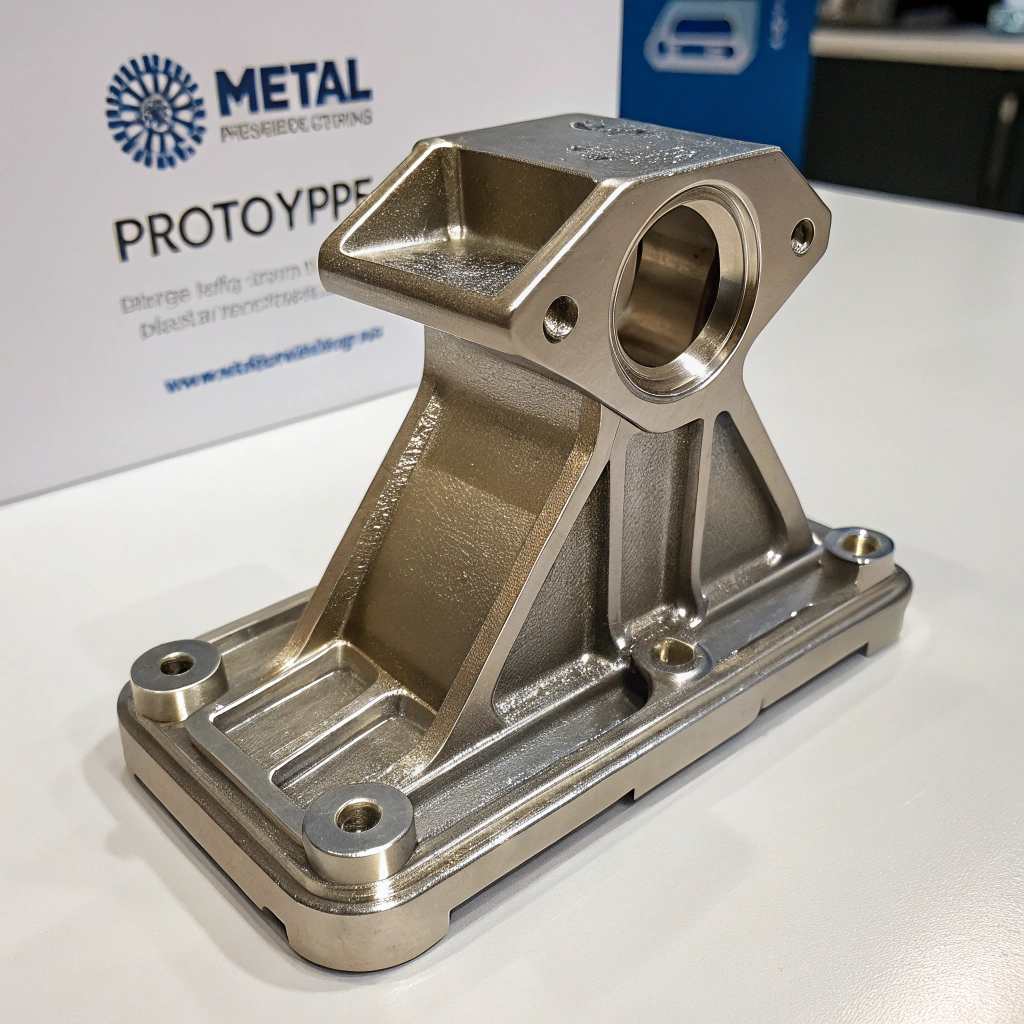

Metal prototyping refers to the process of creating a preliminary model or prototype of a product using metal materials, typically through techniques like CNC machining, 3D printing, or casting. These prototypes are used for testing, design validation, and functionality assessments before full-scale production begins.

Metal prototyping allows engineers and designers to create a physical representation of their ideas in metal, providing an opportunity to evaluate their designs in real-world conditions. By using actual metal materials, manufacturers can assess the mechanical properties, durability, and overall design feasibility of a product early in the development process.

This process is crucial for industries that rely on metal components, such as automotive, aerospace, and industrial machinery, where precision and performance are critical.

Why is Metal Prototyping Important?

Metal prototyping is essential because it allows designers to test their ideas and designs before committing to full production, saving both time and money in the long run. By creating a metal prototype, manufacturers can identify and fix potential issues early in the process, leading to more efficient and reliable final products.

Metal prototyping is important because it helps verify design concepts, test material properties, and ensure manufacturability before mass production. Below are several reasons why metal prototyping is a valuable tool in product development.

Early Testing and Validation

Creating a metal prototype allows for physical testing of a design before committing to large-scale production. This helps identify potential issues such as fitment, functionality, and material performance. By testing prototypes in real-world conditions, designers can make adjustments and refine their designs to improve product quality.

Reducing Development Costs

Prototyping in metal can help reduce the costs associated with manufacturing by preventing expensive mistakes during full-scale production. Identifying design flaws or production challenges early on allows for cost-effective adjustments, ensuring that the final product is both functional and cost-efficient.

Design Flexibility

Metal prototyping enables designers to experiment with various design concepts, materials, and manufacturing methods. With prototypes, designers can evaluate multiple iterations of a product, making it easier to optimize designs for performance, aesthetics, and manufacturability.

Speeding Up Time to Market

By creating and testing metal prototypes quickly, companies can bring their products to market faster. Prototyping allows designers and engineers to rapidly iterate and make changes, accelerating the development cycle and reducing the time between concept and final product.

How to Make a Metal Prototype Efficiently?

Making a metal prototype efficiently requires a clear understanding of the project requirements, the appropriate prototyping methods, and the tools and technologies involved. The process should be optimized to reduce waste, cost, and production time while ensuring high-quality results.

To make a metal prototype efficiently, it’s essential to choose the right prototyping method, select appropriate materials, and streamline the production process. Here are the key steps to consider when creating a metal prototype.

Step 1: Define the Purpose and Requirements

The first step in making a metal prototype is to clearly define the purpose and requirements of the prototype. Understanding the function of the part, the material properties needed, and the intended testing methods will help guide the choice of manufacturing method and materials.

Step 2: Choose the Right Prototyping Method

There are several methods available for creating metal prototypes, each with its own advantages depending on the project:

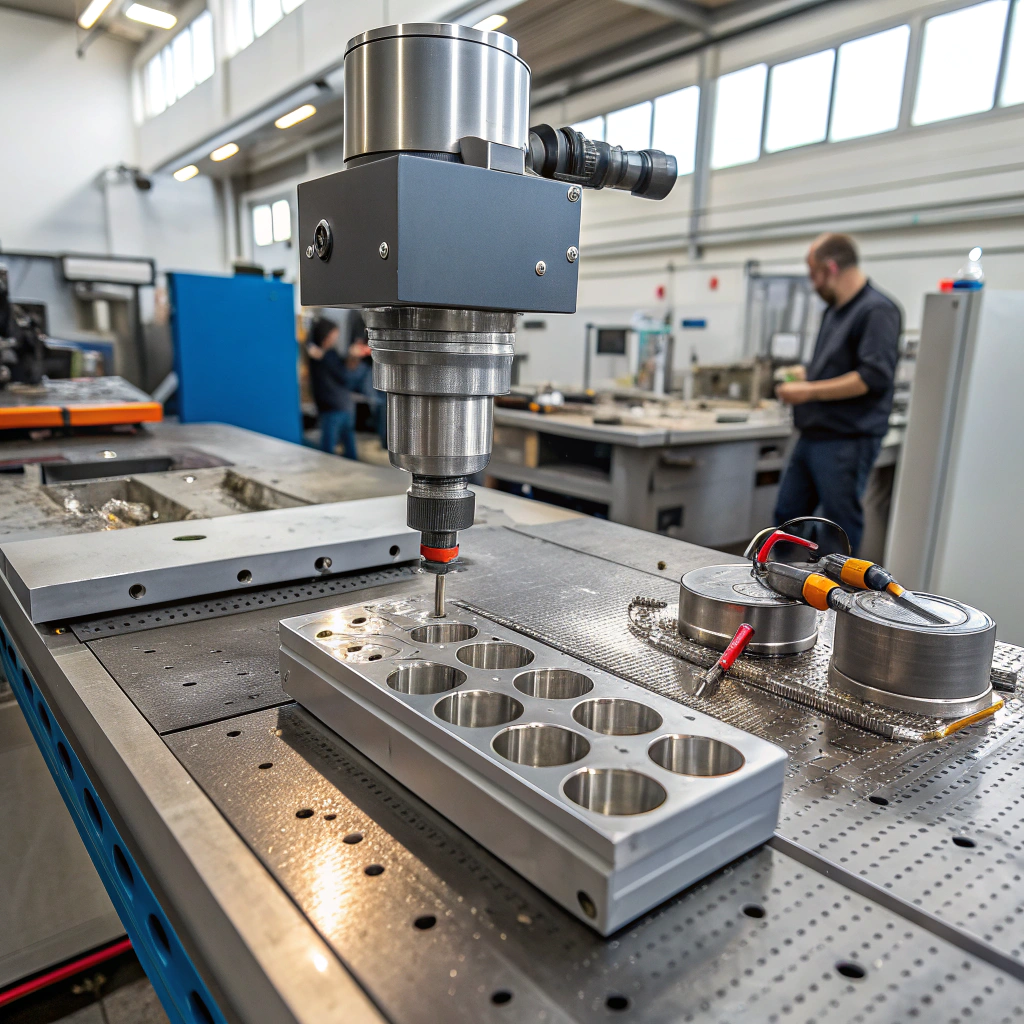

- CNC Machining: A precise method for producing high-quality metal parts from solid blocks of material, ideal for parts that require tight tolerances and intricate details.

- Metal 3D Printing (Additive Manufacturing): A faster and more flexible option for creating complex geometries, especially for low-volume production runs. Metal 3D printing is great for prototypes that have intricate shapes or require rapid iteration.

- Casting: Ideal for producing larger quantities of prototypes, casting allows for creating metal parts by pouring molten metal into molds. This is particularly useful for parts that are too complex for traditional machining methods.

- Sheet Metal Fabrication: A versatile method for creating metal prototypes through bending, cutting, and shaping flat sheets of metal. This is particularly useful for lightweight or thin-walled components.

Step 3: Select Materials Carefully

Selecting the right material for the prototype is essential for ensuring that the final product will perform as expected. Consider factors such as strength, weight, corrosion resistance, and cost when choosing materials. Common metals used for prototyping include aluminum, stainless steel, titanium, and brass.

Step 4: Use Efficient Design Software and Tools

To ensure a smooth prototyping process, it’s important to use efficient design software and tools. Computer-aided design (CAD) software is essential for creating precise 3D models that can be directly used in CNC machining or 3D printing. Additionally, simulations and analyses can help predict how the prototype will behave under different conditions.

Step 5: Optimize the Production Process

Streamlining the production process can significantly improve the efficiency of metal prototyping. This involves minimizing material waste, reducing setup times, and using automated processes where possible. Choosing the right prototyping method and utilizing advanced technologies like robotic arms or automated CNC machines can improve both speed and consistency.

What Are the Trends in Metal Prototyping Technologies?

Metal prototyping technologies are evolving rapidly with advancements in manufacturing processes, materials, and automation. These innovations are enabling faster, more accurate, and cost-effective prototyping solutions, revolutionizing the way products are developed.

The latest trends in metal prototyping focus on automation, 3D printing technologies, and sustainable practices. Here are some of the key trends shaping the future of metal prototyping.

3D Metal Printing (Additive Manufacturing)

3D metal printing continues to gain popularity as it allows for the rapid production of highly complex and customized metal parts. Technologies like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) enable the creation of metal prototypes with intricate geometries that are not possible with traditional manufacturing methods. This trend is particularly beneficial for industries like aerospace, automotive, and healthcare, where customization and lightweight designs are essential.

Hybrid Manufacturing

Hybrid manufacturing, which combines additive and subtractive processes, is emerging as an efficient solution for metal prototyping. This approach allows for the flexibility of 3D printing for complex shapes, while also enabling the precision and material strength of traditional machining methods. Hybrid machines can reduce lead times and costs, making them ideal for rapid prototyping and low-volume production runs.

Automation and Robotics

Automation is transforming the metal prototyping process by increasing efficiency and precision. Robotic arms, automated CNC machines, and automated inspection systems are reducing human error, speeding up production, and ensuring consistency in the final prototypes. The use of AI and machine learning to optimize processes is also becoming more common, further enhancing productivity.

Sustainable Prototyping Practices

As environmental concerns grow, the focus on sustainability in prototyping technologies is increasing. New materials and methods are being developed to reduce waste and energy consumption. For example, metal 3D printing can minimize material waste by using only the exact amount of material required for the prototype. Additionally, the development of recyclable and eco-friendly materials for prototyping is gaining attention in industries aiming for greener production processes.

Cloud-Based Prototyping and Digital Twin Technology

The rise of cloud computing is enabling manufacturers to store and process large amounts of design data, improving collaboration and efficiency in the prototyping process. Digital twin technology, which creates virtual replicas of physical prototypes, is also emerging as a trend. This allows designers and engineers to simulate real-world conditions and make adjustments to prototypes in a virtual environment before physical production.

Conclusion

In conclusion, metal prototyping is a critical process in product development that allows designers to test and validate their designs before full-scale production. By choosing the right prototyping method, selecting appropriate materials, and embracing the latest trends in technology, manufacturers can create high-quality prototypes efficiently. With the continuous advancements in 3D printing, automation, and sustainability, the future of metal prototyping looks promising, providing even more opportunities for innovation and improvement in various industries.