If you're involved in machining or designing mechanical parts, understanding the difference between spotface and counterbore holes can be essential for your work. Let's break it down.

Spotface and counterbore holes serve different purposes in machining. Spotfaces smooth and flatten surfaces around holes, while counterbores create recessed areas for fastener heads. The choice between the two depends on the application and the desired result.

To make an informed decision about whether you need a spotface or counterbore, it’s important to understand their individual applications and how they impact the functionality and appearance of your part. Let’s explore these hole types in more detail.

What is a Spotface Hole?

Have you ever wondered why some holes are surrounded by smooth, flat surfaces? That’s a spotface. It’s more than just a hole – it’s part of a precision process.

A spotface is a shallow, flat area around a hole, typically created to allow a bolt, nut, or washer to sit flush against the surface. It’s ideal for creating a clean seating area for fasteners.

A spotface serves an important function in ensuring that fasteners, like bolts and nuts, have a level and smooth surface for proper seating. Unlike counterbores, spotfaces don’t cut deep into the material. The primary goal is to clean up the surrounding area around a hole, removing rough edges or surface irregularities, which could lead to problems when tightening fasteners.

The key purpose of a spotface is to create a smooth, flat area that ensures a good fit for washers, bolts, or nuts. For example, when assembling machinery, the spotfaced area provides a flat seating surface for fasteners, preventing them from tilting, which could cause failure or misalignment in critical applications.

Spotfacing is commonly used in situations where the fastener needs to fit flush with the material surface or where external surface aesthetics are important. For instance, in structural applications or decorative uses, spotfacing can help achieve a cleaner appearance while enhancing the functionality of the fastening system.

Another benefit of spotfacing is that it reduces stress around the hole. When fasteners are tightened, having an even, flat seating surface can prevent undue pressure on the surrounding material. This can be crucial in materials prone to deformation, such as aluminum or softer metals.

Here’s a comparison of spotface depth versus typical hole size:

| Hole Size | Spotface Depth |

|---|---|

| 10mm | 1-2mm |

| 20mm | 2-3mm |

| 30mm | 3-4mm |

As you can see, spotfaces are shallow compared to the full depth of the hole itself, often extending just far enough to create a clean, flat seating area.

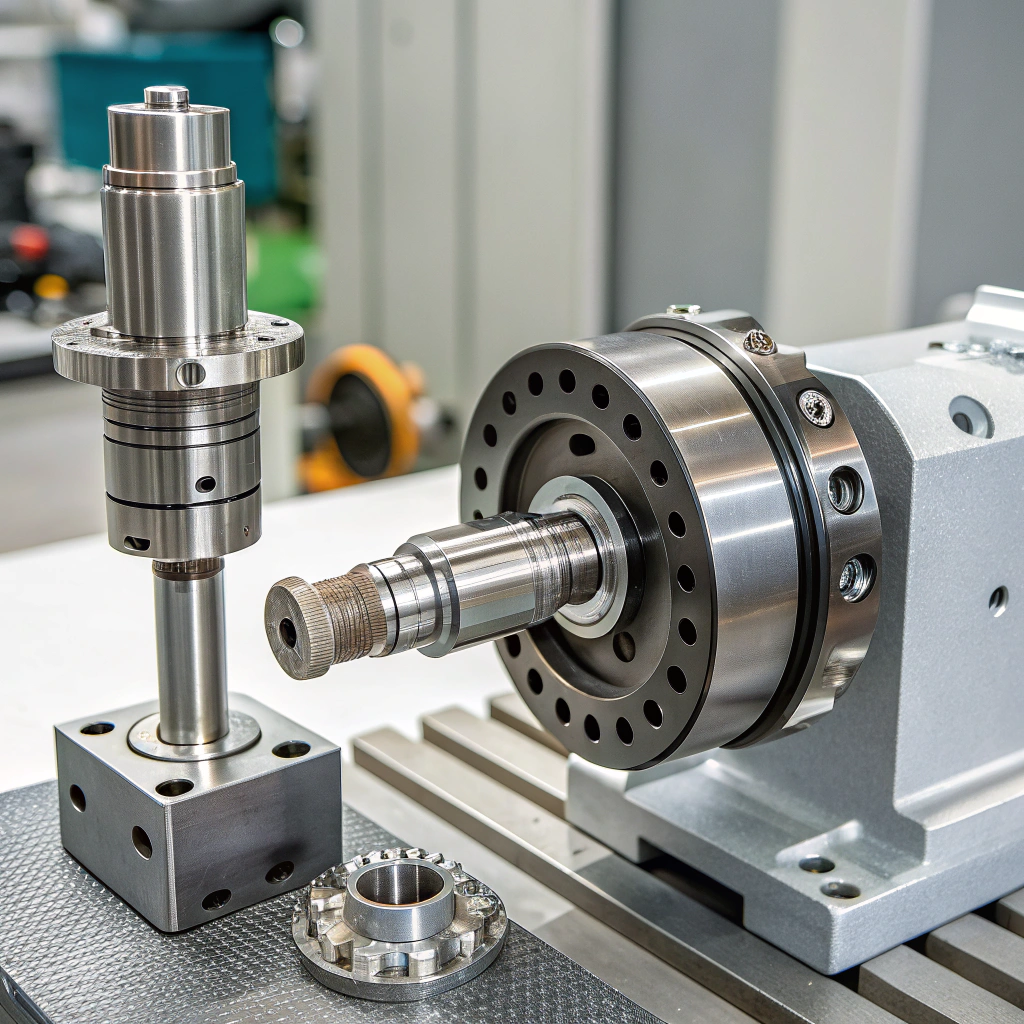

What is a Counterbore Hole?

A counterbore hole might look similar to a spotface at first, but it serves a very different function. So, what exactly makes a counterbore unique?

A counterbore is a cylindrical hole with a flat bottom, designed to allow a fastener, such as a bolt, to sit below or flush with the surface of the material. It's used when you need more depth and a recessed fit.

A counterbore is a type of hole that involves drilling a larger hole at the top of an existing hole. The result is a step-like feature that allows a fastener, such as a bolt head, to sit recessed below the surface. This is particularly useful when you need to conceal the fastener or avoid any interference with other parts that might sit on top of the material.

In applications like machinery and structural components, counterbores are often used to allow the head of a fastener to be flush with the surface, giving the part a cleaner, more streamlined appearance. By using a counterbore, you can prevent the fastener head from protruding, which could otherwise create a physical obstruction or result in poor alignment with adjacent parts.

Counterbores are also useful when the assembly requires a recessed fastener for load distribution. When a fastener is recessed into the material, the load is more evenly distributed across the surface, which can be essential for maintaining the structural integrity of the part. For example, in automotive or aerospace industries, a counterbore ensures that fasteners don’t create stress points on critical components.

Another reason to use a counterbore is for achieving precision in assembly. When parts must fit together with exact tolerances, having a counterbore ensures the fastener is correctly positioned and that there is no play or misalignment.

The depth of a counterbore varies depending on the size of the fastener and the material thickness, but it generally involves drilling deeper than a spotface.

Here’s a typical comparison of counterbore dimensions based on bolt size:

| Bolt Size (mm) | Counterbore Diameter | Counterbore Depth |

|---|---|---|

| M6 | 12mm | 6mm |

| M10 | 20mm | 10mm |

| M12 | 24mm | 12mm |

The counterbore is deeper and typically requires more precision compared to a spotface, as it needs to accommodate the fastener head properly.

When Should You Choose Spotface vs. Counterbore?

Not sure when to use spotfacing or counterboring? Understanding the differences in their purposes will help you decide the best option for your machining needs.

Spotfacing is ideal when you need a flat seating area around a hole for washers or fasteners, while counterboring is necessary when you need to recess the fastener’s head below the surface for a clean finish.

Choosing between spotfacing and counterboring depends largely on the specific requirements of your design and the function of the fasteners. If the primary goal is to ensure that a fastener, such as a nut or bolt, sits flush against the surface, a spotface is the best choice. The shallow, flat area around the hole ensures proper seating without affecting the depth of the hole itself.

On the other hand, if you need the fastener to be recessed into the material, such as in situations where clearance is required for adjacent parts or for aesthetic reasons, a counterbore would be the better option. The recessed nature of the counterbore allows the fastener to sit below the surface, making it suitable for applications where protruding fasteners might cause interference.

In some cases, both processes may be needed. For example, if you're assembling a part where a fastener needs to sit flush with the surface, but you also need to recess the fastener slightly for a cleaner look or better fit, a combination of spotfacing and counterboring may be used in different areas of the part.

It’s also important to consider the material you're working with. Softer materials may require a spotface to ensure proper fastener seating without damaging the surrounding area. Harder materials, on the other hand, may require counterboring for deeper recesses to ensure that the fasteners fit correctly and don’t interfere with other components.

The choice ultimately comes down to the desired function, appearance, and the type of fastener being used. Both processes are simple, but they play crucial roles in creating precise, functional, and aesthetically pleasing parts.

Conclusion

In summary, spotfacing and counterboring serve different yet essential functions in machining. Spotfaces are perfect for creating flat seating areas for fasteners, while counterbores are ideal for recessed fastener heads. Choosing the right method ensures a smoother, more efficient assembly process and better final product.