When you're a manufacturer or product developer, you might not always need thousands of parts at once. Sometimes, you just need ten, maybe fifty. That’s where small batch CNC machining becomes your best option.

Small batch CNC machining is a manufacturing approach where parts are produced in limited quantities, typically under 500 pieces, using computer-controlled machines.

This method allows for rapid production, lower upfront costs, and faster testing of designs. Let's look deeper into how it works and how you can make it work for your business.

What are the benefits of small batch production?

You don’t need to commit to high volumes to access high-quality parts. That’s the core appeal of small batch CNC machining. Whether you’re in R&D or launching a new product, it gives you flexibility and control.

The main benefits include reduced cost of entry, shorter lead times, easier design revisions, and less inventory pressure.

Small batch production offers a way to move fast and stay lean. It allows me to iterate designs without risking too much capital. If a part design needs changes, I can adjust without wasting thousands of units. This is crucial in industries like automotive, medical devices, or aerospace where design revisions are common.

Key Benefits Table

| Benefit | Description |

|---|---|

| Low Upfront Investment | No need for costly molds or large minimum order quantities. |

| Fast Turnaround | Production can start quickly, often within days. |

| Flexibility | Easy to change designs between batches. |

| Reduced Inventory | Produce only what you need, when you need it. |

| Quality Control | Smaller runs are easier to monitor closely for defects. |

Use Case: Early Product Development

In early-stage product development, small batch production lets me test designs in real-world conditions. It also helps with customer feedback before committing to full-scale manufacturing. I once worked with a client who needed aluminum parts for a prototype. We delivered 200 units within a week, which helped them secure investor funding. That speed and flexibility would’ve been impossible with traditional mass production.

How to manage small batch CNC projects?

Managing small batch CNC machining requires careful planning. It’s not just about making fewer parts — it’s about making smart decisions with limited resources.

To manage these projects well, focus on design optimization, clear specifications, reliable suppliers, and strong communication.

Let me walk you through the typical steps I follow when managing a small batch CNC project. This helps me avoid delays and quality issues, especially when customers are overseas.

Step-by-Step Management Guide

Step 1: Finalize Your Design

Always lock in your design before sending it to production. For CNC, every change can mean reprogramming or retooling, which adds cost and time.

Step 2: Choose the Right Material

Pick the material based on function, appearance, and budget. For example, I usually recommend 6061-T6 aluminum for structural parts due to its strength and machinability.

Step 3: Find a Reliable Supplier

Partner with a CNC workshop that has experience with small batch production. Not every factory is set up for low-volume work. I’ve built a network of suppliers who specialize in flexible setups and quick turnarounds.

Step 4: Communicate Clearly

Send 2D drawings, 3D CAD files, and tolerance requirements. Don’t assume your supplier knows what “tight fit” means — be specific.

Step 5: Set Up QA Checks

Even in small batches, quality matters. Ask for inspection reports or do a third-party check. I usually request a few parts from the batch to be inspected before shipping.

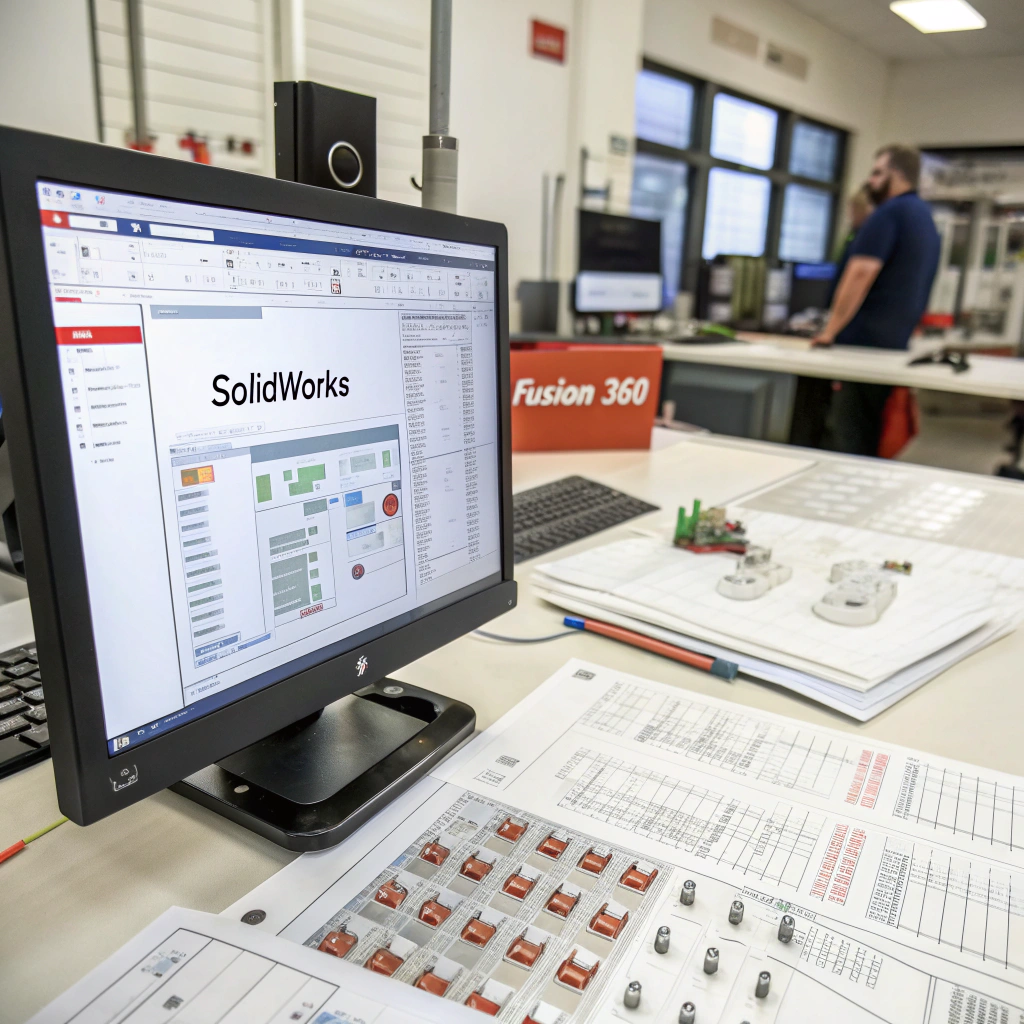

Tools & Templates I Use

| Tool | Purpose |

|---|---|

| CAD software (SolidWorks, Fusion 360) | To create and modify part designs. |

| Tolerance Table | To communicate acceptable deviation ranges. |

| Project Timeline Sheet | To track order status, lead times, and delivery. |

| Supplier Checklist | To assess whether a factory is suitable for small batch jobs. |

These steps help ensure smooth production, even with complex or custom parts.

What are the new trends in low-volume CNC machining?

The world of low-volume CNC machining is evolving fast. New technology, automation, and global demand are reshaping how we approach small batch production.

The latest trends include digital quoting systems, hybrid manufacturing, AI-driven toolpaths, and eco-friendly material sourcing.

I’ve seen a noticeable shift toward more intelligent workflows. More clients are asking for instant quotes and real-time tracking. At the same time, sustainability is becoming a key priority.

Trend 1: Digital Manufacturing Platforms

Platforms like Xometry and Fictiv are popular for a reason. They offer quick quotes, design feedback, and supply chain transparency. While I still prefer direct factory communication for custom jobs, these tools speed up procurement.

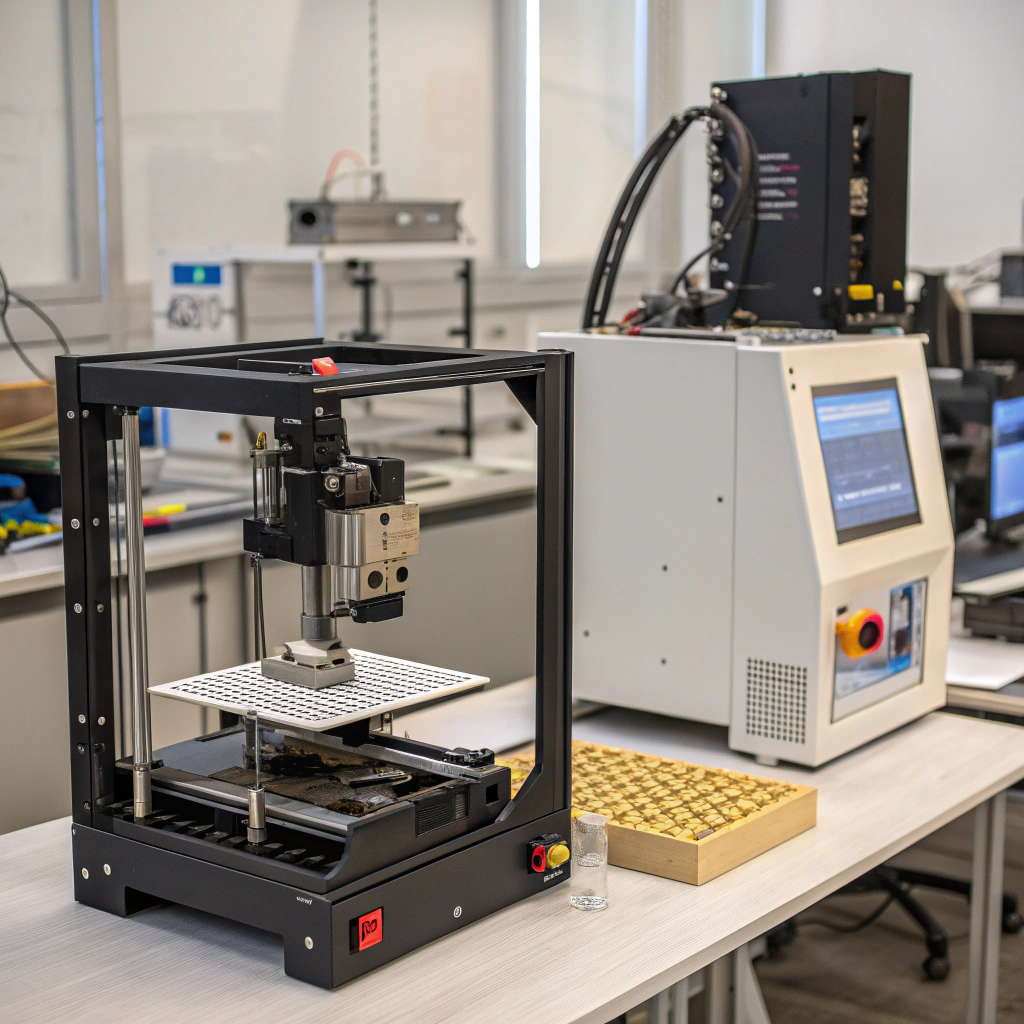

Trend 2: Hybrid Processes (CNC + 3D Printing)

Combining 3D printing with CNC is a big game changer. I use 3D printing for early concept validation, then move to CNC for final production. This mix saves time and gives clients more flexibility.

Trend 3: AI and Automation

CAM software is getting smarter. Some systems now generate toolpaths using AI, which reduces programming time and tool wear. I’ve used these on complex aluminum profiles, and the results were impressive.

Trend 4: Sustainable Materials

There’s growing demand for recycled aluminum and energy-efficient processes. Clients from Europe especially ask about our material sourcing and carbon footprint.

Future Outlook Table

| Trend | Impact |

|---|---|

| AI in Toolpath Generation | Faster programming, lower costs |

| Cloud-Based Collaboration | Real-time updates, better communication |

| Recycled Aluminum Use | More eco-friendly, meets regulatory standards |

| Automated Quality Inspection | Higher consistency, faster feedback |

By staying ahead of these trends, I can offer more value to clients, especially those in fast-moving or regulated industries.

Conclusion

Small batch CNC machining is a powerful tool for agile manufacturing. It brings speed, flexibility, and precision to projects that don’t need large volumes. From prototyping to pilot runs, this method fits well with today’s fast-changing product cycles.