In today’s manufacturing world, CNC machining has become a cornerstone of precision and efficiency. But what exactly does production CNC machining entail, and why is it so critical to modern production lines?

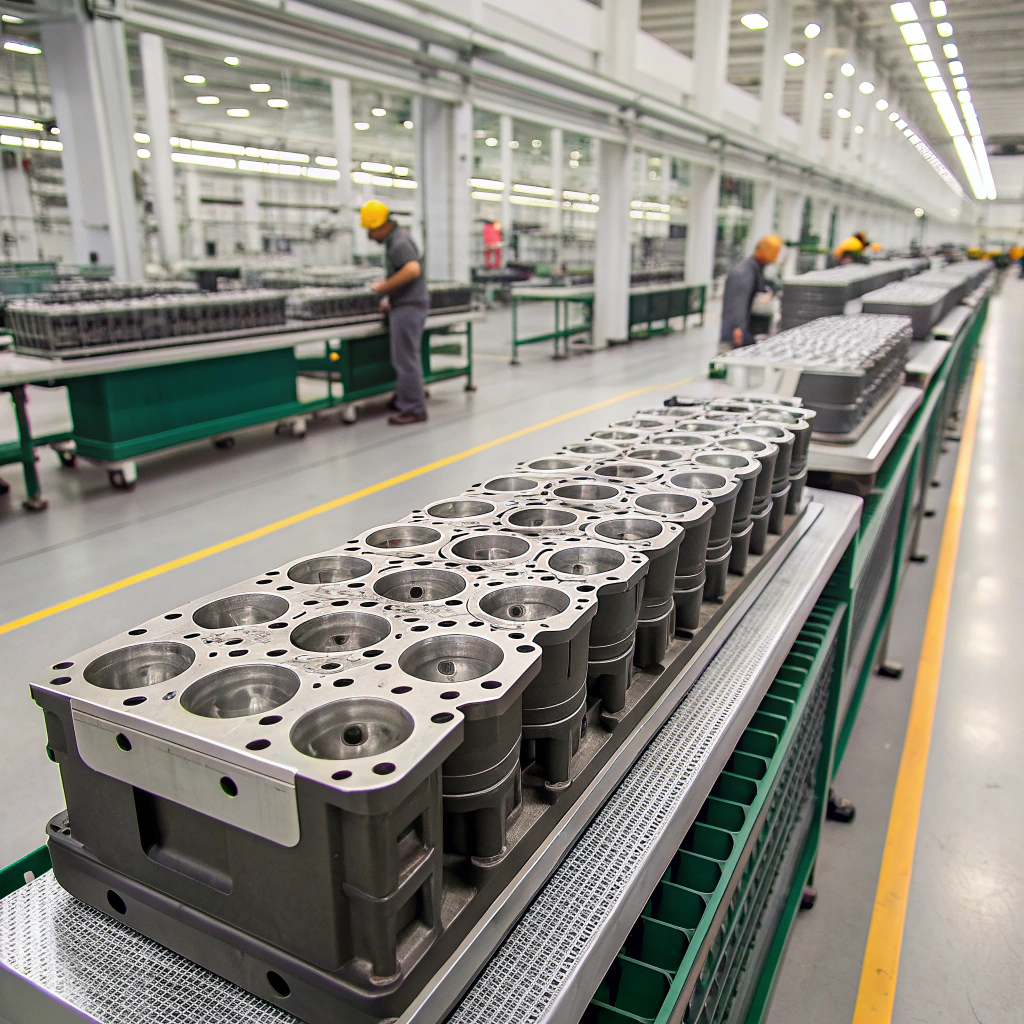

Production CNC machining is a highly automated manufacturing process used to create parts in large quantities with precision and consistency. This process involves using computer-controlled machines to cut, shape, and finish materials like metal, plastic, and composite to exact specifications.

The efficiency and precision of CNC machining have made it an essential part of many industries, especially those requiring high-volume production, such as automotive, aerospace, and consumer electronics. But how is it managed, and what are the latest trends shaping the future of large-scale CNC manufacturing?

What Are the Benefits of Production CNC Machining?

Production CNC machining offers several key advantages, making it the go-to solution for manufacturers looking to produce large volumes of parts with tight tolerances.

The main benefits include high precision, repeatability, and the ability to produce complex parts that would otherwise be difficult or impossible to make manually. It also reduces labor costs and material waste, ensuring that production remains cost-effective and efficient.

Precision and Consistency

CNC machines operate based on computer programming, which ensures the precision and consistency of every part produced. Once the program is loaded into the machine, it can produce thousands of identical parts with little variation in size or quality. This level of consistency is especially important in industries where even minor deviations can cause major issues, such as aerospace or medical device manufacturing.

Reduced Labor and Increased Speed

CNC machines automate much of the machining process, which reduces the need for manual labor and speeds up production. This not only lowers labor costs but also increases throughput. CNC machines can run for extended periods without requiring breaks, making them ideal for continuous production runs.

Capability for Complex Geometries

CNC machines can create intricate designs and complex geometries that would be difficult, if not impossible, with traditional manual methods. The use of multi-axis machines allows for complex cuts, engravings, and 3D shapes that can be made with high precision. This is particularly useful in industries like automotive and aerospace, where complex part designs are common.

How to Manage Production CNC Operations?

Managing production CNC operations requires careful planning and constant monitoring. To ensure optimal efficiency, there are several key factors to consider, from pre-production planning to post-production quality control.

Pre-Production Planning

Before any machining begins, it’s important to ensure that parts are designed for manufacturability. This means designing parts that are not only functional but also easy to machine, reducing the likelihood of production delays. Choosing the right material is also crucial—some materials are more difficult to machine than others, which can affect both the cost and speed of production.

Additionally, programming the CNC machine with the correct tool paths is vital. Poor programming can lead to inefficient machining, increased cycle times, and excessive tool wear. It's important to verify that the machine is correctly set up and that all the necessary tools are available.

Machine Setup and Calibration

Before starting production, each CNC machine needs to be properly set up and calibrated. This includes loading the correct program, checking for tool wear, and ensuring that all components are working correctly. Calibration checks should be performed regularly to ensure the machine is performing to specifications.

Ongoing Monitoring and Quality Control

Throughout the production process, continuous monitoring of both the machines and parts being produced is essential. Automated sensors and quality control systems can help detect any issues early, reducing the likelihood of defective parts reaching the customer. Regular sampling and inspection should be conducted to maintain part quality.

What Are the Trends in Large-Scale CNC Manufacturing?

The world of CNC machining is constantly evolving. In recent years, several trends have emerged that are shaping the future of large-scale CNC manufacturing. These trends focus on increasing efficiency, sustainability, and adaptability.

Automation and Robotics Integration

One of the biggest trends in CNC machining is the increased use of automation and robotics. By integrating robotic arms and automated material handling systems, manufacturers can increase speed, reduce human error, and lower labor costs. These automated systems can handle tasks such as loading and unloading parts, changing tools, and even conducting quality inspections.

IoT Integration

The Internet of Things (IoT) is transforming CNC machining by connecting machines to the internet, allowing manufacturers to monitor performance and detect potential issues in real time. Sensors embedded in CNC machines can provide data on everything from temperature to tool wear, allowing for predictive maintenance and reducing unexpected downtimes. This type of connected data improves decision-making and enhances overall efficiency.

Additive Manufacturing Integration

CNC machining and additive manufacturing (3D printing) are increasingly being used together in what is known as hybrid manufacturing. This approach combines the benefits of both subtractive and additive processes. CNC machines handle tasks like cutting and milling, while 3D printers are used for layer-by-layer material deposition. This hybrid method is particularly useful for creating complex parts with both subtractive and additive features.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are making their way into CNC machining operations. These technologies help optimize production by analyzing large amounts of data to predict machine failures, optimize cutting parameters, and even adjust the machining process in real time. AI and ML can significantly reduce the need for manual intervention while improving machine uptime and efficiency.

Digital Twins and Simulation

The use of digital twins—virtual models of physical CNC machines or production lines—is becoming more common. These virtual models allow manufacturers to simulate the entire production process before physical machining begins, reducing setup times and improving the accuracy of the final product. Simulating the process also helps identify potential issues before they occur, reducing the likelihood of costly errors.

Sustainability and Energy Efficiency

Sustainability is another major trend in CNC machining. Manufacturers are looking for ways to reduce their carbon footprint, optimize energy usage, and minimize material waste. Many modern CNC machines are more energy-efficient, and manufacturers are adopting green practices such as recycling waste materials and reducing water usage during the production process.

Cloud-Based Manufacturing Management

Cloud-based systems are increasingly being used to manage CNC machining operations. These systems allow manufacturers to track production in real-time, monitor machine health, and collaborate across multiple locations. The ability to access and share data from anywhere increases efficiency and helps ensure that operations run smoothly.

Conclusion

Production CNC machining has revolutionized manufacturing by offering precision, efficiency, and the ability to produce complex parts at scale. With ongoing advancements in automation, AI, and sustainability, the future of CNC machining is bright. By embracing these trends, manufacturers can continue to improve productivity and remain competitive in an ever-evolving industry.