If you’re developing a high-performance product, choosing the right material and process is key—but it’s easy to get overwhelmed by technical jargon.

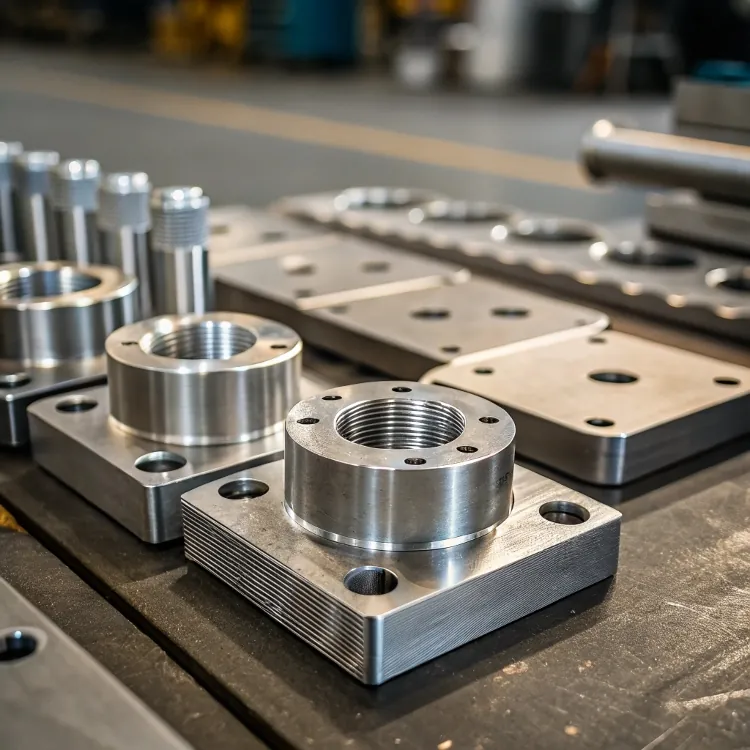

CNC machined aluminum refers to aluminum parts shaped by precision computer-controlled tools, known as CNC machines. This method ensures consistent quality, tight tolerances, and a smooth finish.

Understanding what CNC machined aluminum is can help you make informed decisions, whether you're designing a prototype or preparing for mass production.

Is CNC Aluminum Good?

If you're unsure whether CNC aluminum is reliable, you're not alone. Many engineers and buyers ask this when comparing different materials.

Yes, CNC aluminum is excellent for applications requiring strength, precision, corrosion resistance1, and lightweight performance. It is widely favored for both industrial and consumer applications.

CNC aluminum combines the benefits of aluminum as a metal—lightweight, corrosion-resistant, easy to work with—with the accuracy and repeatability of CNC machining. It can be machined into very complex shapes, with tolerances as tight as ±0.01 mm. It is also compatible with multiple surface treatments like anodizing, sandblasting, and brushing.

Common Properties of CNC Aluminum

| Property | Description |

|---|---|

| Material Hardness | Medium (can be strengthened via alloying) |

| Machinability | Excellent, especially 6061 and 6063 |

| Corrosion Resistance | High, especially after anodizing |

| Weight | Lightweight compared to steel |

| Surface Finishing | Smooth, customizable with coatings |

These features make CNC aluminum a preferred material across many engineering projects. From consumer electronics to aerospace, its adaptability is impressive.

What Are the Advantages of CNC Machined Aluminum Parts?

You might wonder why so many engineers choose aluminum for CNC machining over plastics or steel. That’s because it offers a very unique mix of benefits.

CNC machined aluminum parts are strong, lightweight, corrosion-resistant, and offer tight dimensional control—making them ideal for critical components in many industries.

Aluminum is easy to cut and responds well to milling and turning processes. Its low melting point reduces tool wear and improves surface finishes. That helps manufacturers save cost, time, and effort—while ensuring high precision2.

Key Benefits at a Glance

| Benefit | Explanation |

|---|---|

| High Precision | CNC machines can create parts with complex geometry accurately |

| Lightweight Strength | Perfect for applications that need weight reduction without losing strength |

| Versatile Finishing | Compatible with anodizing, painting, polishing, etc. |

| Cost-Efficient | Shorter cycle times mean faster production and lower costs |

| Eco-Friendly | Aluminum is fully recyclable |

Many of our clients in industries like medical devices and consumer electronics rely on CNC aluminum because it ensures consistent performance across batches.

How Is Aluminum Prepared Before CNC Machining?

Getting high-quality CNC parts doesn’t start at the machine—it starts with how you prep the raw material. Many problems can be avoided here.

Before CNC machining, aluminum is selected by grade, inspected, cleaned, and cut into manageable sizes. This ensures accuracy and prevents defects during processing.

Preparation begins with selecting the right aluminum grade3. The most common types are 6061, 6063, and 7075. Each has its own strength, hardness, and corrosion resistance levels. After choosing the material, it is inspected for surface damage or internal flaws, often using ultrasonic or dye-penetrant testing.

Preparation Steps

1. Material Selection

We choose the aluminum type based on your part’s mechanical and thermal needs.

2. Surface Cleaning

Any surface contaminants like oil or oxidation are cleaned off with solvents or mild abrasives.

3. Saw Cutting

Bars or sheets are cut down to the appropriate size to fit the CNC machine.

4. Stress Relief

For some grades, especially thick blocks, we apply heat treatment to reduce internal stress before machining.

5. Fixturing Planning

We design how the material will be clamped to the machine bed to minimize movement and distortion.

A well-prepped aluminum block results in a cleaner finish, reduced tool wear, and better accuracy throughout the entire CNC process.

What Industries Commonly Use CNC Machined Aluminum?

It’s easy to think CNC aluminum is just for fancy consumer gadgets—but it plays a key role in a wide range of industries.

Industries that use CNC machined aluminum include aerospace, automotive, medical devices4, electronics, robotics, and industrial automation.

The combination of high strength-to-weight ratio and excellent thermal/electrical conductivity makes CNC aluminum the go-to choice for both small and large-scale manufacturing projects.

Examples of Application by Industry

| Industry | Common Aluminum Parts |

|---|---|

| Aerospace | Structural brackets, interior frames |

| Automotive | Gear housings, heat exchangers, dashboards |

| Medical Devices | Surgical handles, robotic arms, connectors |

| Electronics | Housings, heat sinks, display bezels |

| Robotics | Arms, base frames, motor mounts |

| Automation Equipment | Sensor brackets, covers, moving parts |

At sinoextrud, we serve clients from all these industries. Whether it's for prototypes or full-scale production, CNC machined aluminum5 helps them meet both technical and market demands efficiently.

Conclusion

CNC machined aluminum offers precision, flexibility, and reliability across industries. It's a smart choice for anyone building functional, high-performance components.

-

Learn how CNC aluminum's corrosion resistance stacks up against other materials, ensuring durability in various environments. ↩

-

Discover the significance of high precision in CNC machining and how it impacts product quality and performance. ↩

-

Understanding aluminum grades is crucial for selecting the right material for CNC machining, ensuring optimal performance and quality. ↩

-

Learn about the importance of CNC machined aluminum in medical devices, enhancing precision and reliability in healthcare. ↩

-

Explore the advantages of CNC machined aluminum and how it enhances efficiency across multiple sectors. ↩