I’ve seen industrial systems fail because the wrong alloy was picked. The heat builds, components degrade, downtime hits hard.

Choosing the right alloy grade for heat sinks means balancing thermal conductivity, strength, cost and manufacturability for industrial use.

In the rest of this article I’ll walk you through key questions about heat sink alloys—from what performs best, to how grades affect durability, what tests matter, and when you need specialized alloys for tough environments. Let’s dive in.

Which alloys offer optimal heat dissipation?

Imagine your system overheating because the alloy slows the heat flow—this is a serious risk.

Alloys such as 6063 and 6061 in the 6000‑series aluminium family are widely used for heat sinks because they offer a good balance of thermal conductivity and structural performance.

When I evaluate alloys for heat sinks, one of the first things I check is thermal conductivity (k, W/m·K). A higher value means heat moves more readily from the heat source into the sink and then into the surrounding air. For example, the alloy Aluminium 1060 (a nearly pure aluminium grade) has very high thermal conductivity (~229 W/m·K) but is mechanically weak and less practical for rugged industrial systems.

Meanwhile, common extruded alloys like Aluminium 6063 come in around ~200 W/m·K depending on temper, and Aluminium 6061 around ~150‑170 W/m·K.

But conductivity is only part of the story. You also need an alloy that can be extruded into a finned profile, that has enough strength for mounting or vibration loads, and that offers corrosion resistance and manufacturability. For example, 6063 is highly extrudable, good for intricate fins, and takes anodising well.

Here is a simple comparison:

| Alloy | Approximate Thermal Conductivity | Strength / Extrudability | Typical Use |

|---|---|---|---|

| 1050 (pure‑like) | ~229 W/m·K | Low strength, very soft | Simple, low‑load heat sinks |

| 6063 | ~200‑218 W/m·K | Good extrusion, moderate strength | General industrial heat sinks |

| 6061 | ~150‑170 W/m·K | High strength, decent extrusion | Heat sinks with structural load or harsher duty |

When I’m specifying for a customer, I’ll often choose 6063 when the primary goal is the best fin geometry and thermal performance, but I’ll shift to 6061 when there’s added mechanical load or ruggedness needed.

Also, keep in mind that beyond material choice, the geometry of the heat sink, the fin density, the airflow, and the interface with the heat‑source matter a lot. An optimized fin profile in a slightly lower conductivity alloy can outperform a poor design in a high‑conductivity alloy. That’s why for industrial use we treat geometry, alloy, tooling and finish all together.

Finally, while many think “copper is best” because of its thermal properties (~400 W/m·K in pure copper), copper’s cost, weight, and extrusion difficulty often make aluminium alloys a more realistic choice in large‑scale industrial heat sinks.

How do alloy grades impact heat sink durability?

Durability matters. If your heat sink cracks, corrodes, or deforms, your cooling fails.

Alloy grades impact durability through mechanical strength, corrosion resistance, and fabrication robustness—for example stronger alloys mitigate vibration damage, and those with better surface treatments resist harsh environments.

When I assess durability, I look at three main aspects: mechanical strength and load‑bearing capacity, corrosion / surface degradation, and how the alloy behaves under thermal cycling and fatigue.

Mechanical strength & fabrication

Alloys like 6061 give higher tensile strength compared to 6063. 6061‑T6 has significant strength advantages making it suitable where the heat sink is also a structural component.

If a heat sink is mounted on heavy equipment, experiences vibration, or must maintain flatness for thermal contact, you might choose 6061 rather than 6063—even if you sacrifice some thermal conductance.

Corrosion resistance & surface treatment

In industrial environments, heat sinks might see humidity, chemical exposure, salt spray, or outdoor conditions. The alloy choice plus surface finish (anodising, electro‑coating) influences durability. Aluminium forms a thin oxide layer, giving passive corrosion resistance. But added alloying elements and extruded shapes may expose intermetallics or defects that degrade in harsh conditions.

If you choose a soft alloy for best conductivity but low strength (say 1050), you risk deformation, creep under load, or damage in a high vibration environment. So durability becomes a limiting factor.

Thermal cycling & fatigue

In industrial use, heat sinks often face repeated thermal cycling—power systems turning on/off, ambient temperature swings, high loads. These cycles stress the material through expansion/contraction, and if the alloy has low fatigue strength or poor thermo‑mechanical stability, micro cracks or warpage may form over time.

Implications for design and supply

As I plan for industrial applications, I include the following:

- Select an alloy grade that meets the mechanical environment (e.g., vibration, mounting loads)

- Ensure the surface treatment is compatible with the environment (e.g., salt spray, chemical exposure)

- Confirm that the supplier provides extrusion accuracy, flatness, and dimensional control

- Discuss minimum wall thicknesses and extrusion tolerances with the alloy choice in mind

In summary: the alloy grade matters a lot for durability. Even an alloy with excellent thermal conductivity can fail prematurely if it cannot handle the mechanical and environmental load.

What tests verify industrial alloy performance?

You don’t want to guess whether your alloy will perform—you need proof via testing.

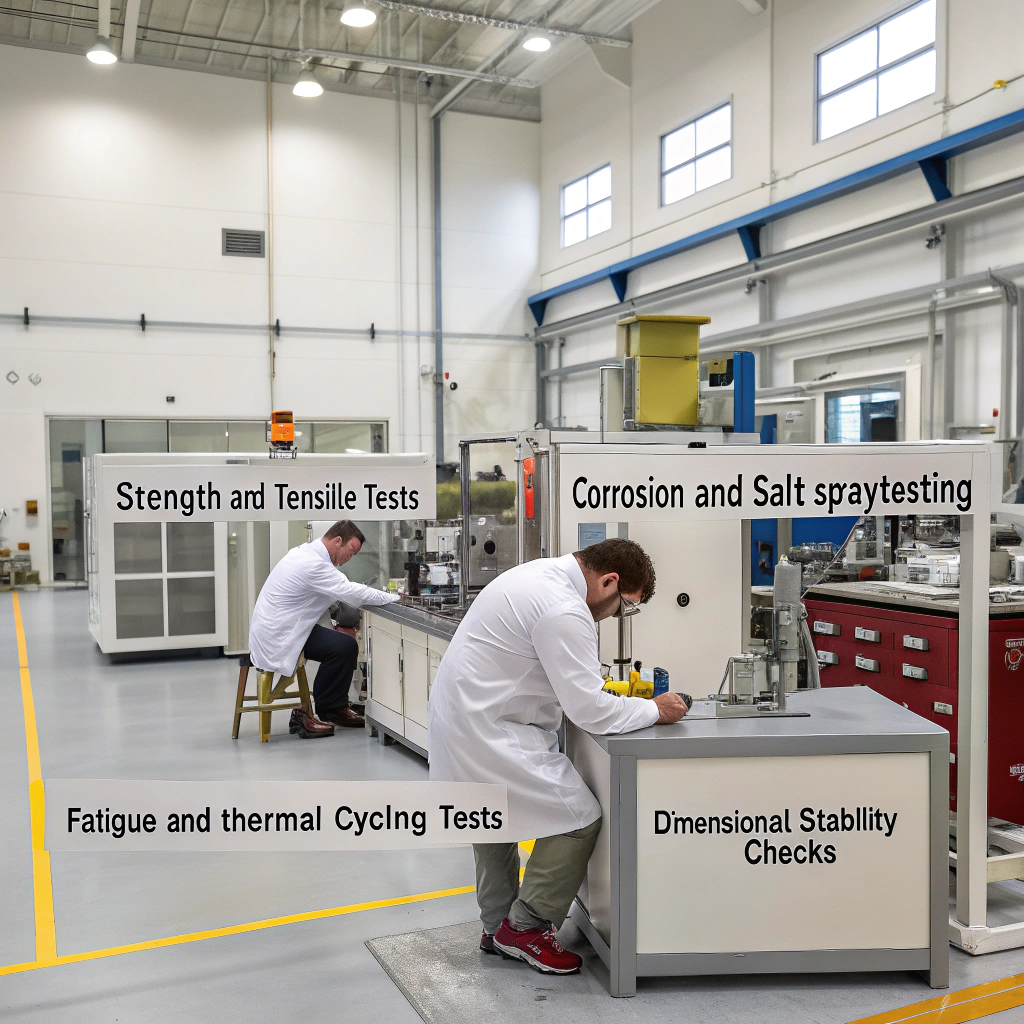

Key tests to verify alloy performance for heat sinks include thermal conductivity measurement, mechanical strength/tensile tests, corrosion/salt spray testing, fatigue/thermal cycling tests and dimensional stability checks.

For me, verifying alloy performance is about gathering data across thermal, mechanical and environmental domains. Here are the major test categories I use and why they matter:

1. Thermal conductivity / heat transfer test

Measure the alloy’s thermal conductivity or the finished product’s thermal resistance (°C/W) under realistic load and geometry conditions. It verifies whether the material and design meet the system’s cooling needs.

2. Mechanical strength / tensile & yield tests

Check if the alloy matches its published yield strength, tensile strength, and elongation specs. This confirms the material can handle mounting forces and vibrations without deformation or cracking.

3. Fatigue / thermal cycling tests

Industrial heat sinks often face repeated heating/cooling cycles. You must test for cracking, warpage, or thermal resistance drift. It confirms the longevity of both the alloy and the joint.

4. Corrosion / environmental tests

Use salt spray or humidity chamber testing to assess corrosion resistance, especially for outdoor, marine or chemical-exposed heat sinks. Surface treatments like anodising help, but base alloy still matters.

5. Dimensional stability / interface testing

Check that extrusion and machining maintain flatness and contact surfaces after processing and during use. Poor flatness reduces thermal contact, raising temperature and reducing reliability.

| Test Category | Why It Matters | Typical Specification |

|---|---|---|

| Thermal conductivity / resistance | Measures cooling performance | ≤ specified °C/W under load |

| Tensile / yield strength | Confirms durability under load | Matches alloy grade spec |

| Thermal cycling / fatigue | Reliability under changing temps | No cracks or warpage |

| Corrosion / environmental | Resistance to degradation | Salt spray hours passed |

| Dimensional / interface | Ensures good heat transfer | Flatness and finish within spec |

I treat testing as part of alloy selection—not something to add later. A good supplier will offer this data or help arrange tests.

Are specialized alloys needed for harsh environments?

When the environment is extreme—salt spray, high vibration, high temperature—you might need special alloys beyond the standard ones.

Yes, for harsh environments you often need specialized alloys (or surface treatments) that deliver corrosion resistance, higher strength, thermal stability and compatibility with rugged conditions.

In industrial use, “harsh environment” can mean outdoors near the sea, in chemical plants, exposed to wide temperature swings or heavy vibration. Standard 6063 or 6061 may not always be enough.

What counts as harsh?

- Marine air or salt fog

- Outdoor exposure with heat and rain

- Environments with acid, oil mist or chemical spray

- Power modules under high vibration (e.g., transport)

- Places with thermal shocks, frequent power on/off cycles

Alloy choices for tough jobs

- Use anodised 6063 or 6061 with thick oxide layer for better corrosion

- Consider 1050A only when strength is not needed, like passive radiators

- For marine or aggressive chemical exposure, copper or AlSiC composites may be required

- Coated or painted surfaces add protection, but base alloy must still be suitable

These setups increase costs. So, I match alloy to the application carefully. Many times, 6063 with hard anodising works well. But for extreme conditions, clients may need more exotic materials.

Conclusion

In choosing alloy grades for industrial heat sinks, I look first at thermal performance, then durability (mechanical plus environment), then validate via testing, and finally assess whether the environment demands specialized alloys. Balancing conductivity, strength, manufacturability and cost is key for a successful system.