CNC fabrication is a precise manufacturing process that uses computer-controlled machines to create complex and accurate parts from raw materials. CNC (Computer Numerical Control) machines automate the fabrication process, improving speed, precision, and consistency. This technology has revolutionized industries like metalworking, woodworking, and plastic fabrication.

CNC fabrication integrates advanced machinery and digital controls to produce high-quality, custom parts. The process begins with a digital design, which is translated into machine instructions, and the machine cuts, shapes, or assembles materials accordingly. In this article, we’ll explore how CNC fabrication is performed, why it enhances fabrication quality, which projects benefit from it, and where it fits into the overall production process.

CNC fabrication is a game-changer for industries that need precision and efficiency in their manufacturing processes. Let’s dive deeper into how this technology works and why it’s so widely used.

How is CNC Fabrication Performed?

CNC fabrication is performed using specialized computer-controlled machinery. The process begins with a digital design, often created in CAD (Computer-Aided Design) software. Once the design is ready, it’s converted into machine-readable instructions, typically G-code, which guides the CNC machine in its operations. This allows the machine to follow precise paths and perform various operations like cutting, drilling, milling, or turning.

Step-by-Step CNC Fabrication Process:

- Design Creation: The first step in CNC fabrication is creating a design using CAD software. This design includes detailed specifications for the part or product.

- G-code Generation: The CAD design is then converted into G-code, a set of commands that tell the CNC machine how to move and operate.

- Machine Setup: The raw material is loaded onto the CNC machine, and the machine is calibrated to the necessary settings.

- Fabrication: The CNC machine follows the G-code to perform the required tasks, such as cutting, shaping, or assembling the material.

- Post-processing: After fabrication, the part may undergo additional processes, such as cleaning, finishing, or assembly.

By automating these steps, CNC fabrication eliminates many of the errors and inconsistencies associated with manual fabrication, resulting in higher-quality parts and more efficient production.

Why Does CNC Improve Fabrication Quality?

CNC fabrication improves fabrication quality by eliminating human error, increasing precision, and providing greater control over the production process. With CNC machines, parts can be produced with tight tolerances and consistent quality, ensuring that each piece meets the exact specifications required.

Ways CNC Improves Fabrication Quality:

- Precision: CNC machines are highly accurate, often capable of achieving tolerances of a fraction of a millimeter. This ensures that each part meets the exact dimensions specified in the design.

- Consistency: Once a CNC program is set, the machine can replicate the same process for every part, ensuring consistency throughout a production run.

- Reduced Human Error: Automated processes reduce the chances of mistakes that can occur during manual fabrication, such as misalignments or incorrect measurements.

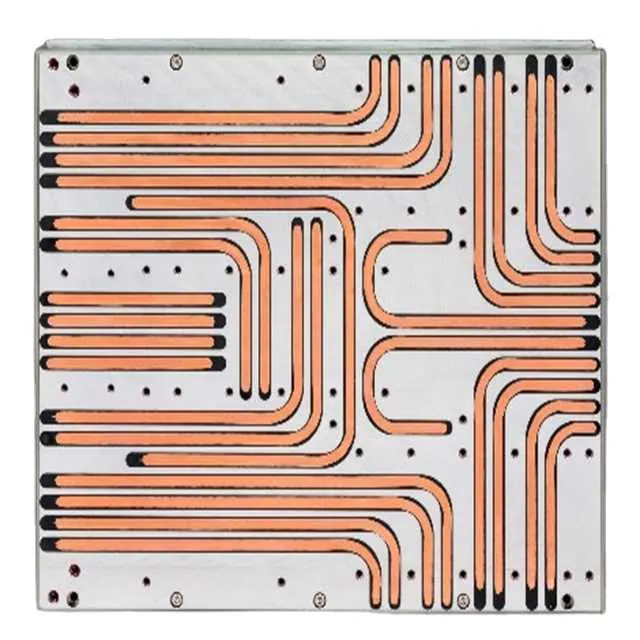

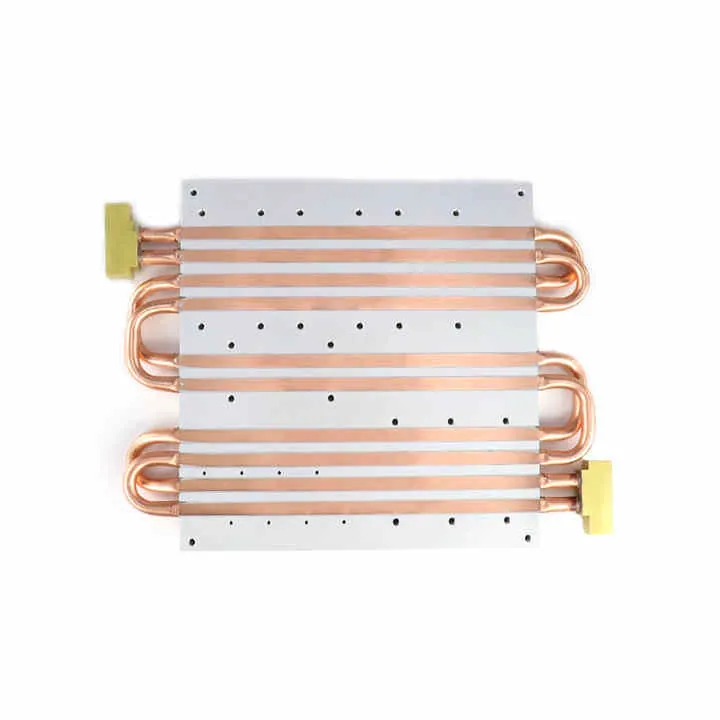

- Complex Geometry: CNC machines can handle complex shapes and geometries that would be impossible or very difficult to achieve by hand, providing greater design freedom.

With CNC fabrication, manufacturers can produce highly accurate parts, even in high-volume runs, while ensuring that each piece matches the design specifications exactly.

Which Projects Benefit from CNC Fabrication?

CNC fabrication is ideal for projects that require high precision, repeatability, and complex geometries. It is particularly useful for industries that produce custom or intricate parts on a large scale, as CNC machines can quickly adapt to different designs without sacrificing quality.

Projects That Benefit from CNC Fabrication:

| Industry | Common Projects | Benefits of CNC Fabrication |

|---|---|---|

| Aerospace | Engine components, turbine blades | High precision, lightweight materials |

| Medical | Surgical instruments, implants | Custom parts, exact tolerances |

| Automotive | Engine blocks, transmission parts | Consistent quality, complex geometries |

| Electronics | Circuit boards, connectors | Small, precise parts, quick turnaround |

For example, in the aerospace industry, CNC fabrication is used to produce highly detailed and lightweight engine parts that must meet strict performance standards. Similarly, the medical industry relies on CNC fabrication for creating customized implants or surgical instruments, where precision is crucial.

Where Does CNC Fabrication Fit in Production?

CNC fabrication fits into the production process as a critical step in manufacturing complex and precise components. It is often used in conjunction with other manufacturing processes, such as injection molding, 3D printing, and welding, to create fully functional products.

Role of CNC Fabrication in Production:

| Stage of Production | Role of CNC Fabrication |

|---|---|

| Prototyping | CNC fabrication is often used to create prototypes, allowing designers to quickly test and iterate their designs. |

| Mass Production | Once a design is validated, CNC fabrication can be used for mass production of parts, ensuring consistency and efficiency. |

| Final Assembly | CNC machines can also be used for finishing touches, such as drilling holes, threading, or adding complex details to components. |

CNC fabrication can streamline the production process by reducing the time spent on manual operations, minimizing waste, and improving overall efficiency. It fits perfectly in industries that require precision and high-quality components, such as aerospace, automotive, medical, and electronics.

Conclusion

CNC fabrication is a vital technology in modern manufacturing. By using automated processes to create precise parts, CNC fabrication improves quality, speed, and consistency in production. Whether in aerospace, automotive, or medical industries, CNC fabrication is the key to producing complex, high-quality components efficiently and accurately.