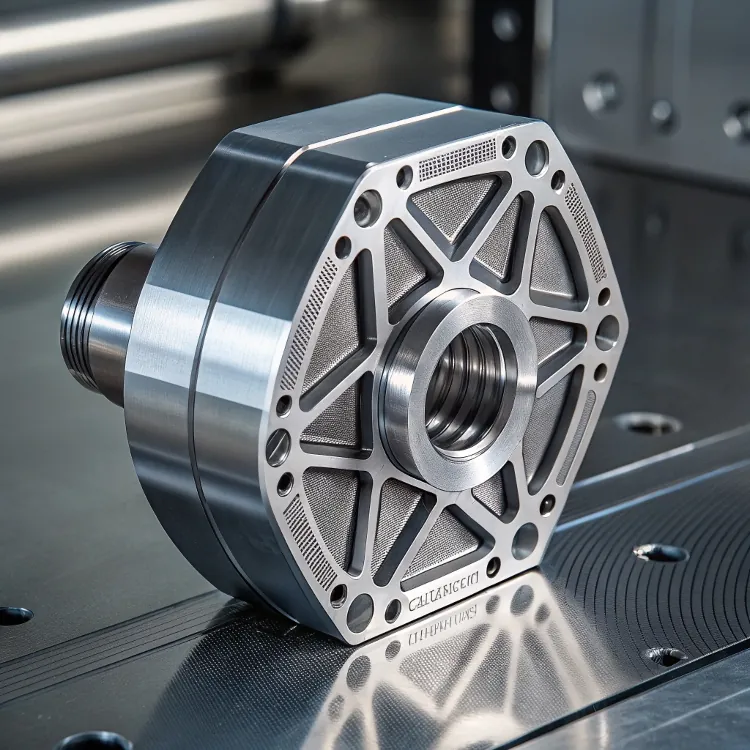

When you're designing a product with tight tolerances, tricky geometries, or sleek looks, the question always comes up: is CNC aluminum worth it?

Yes, CNC aluminum is often worth it due to its ideal balance of strength, weight, machinability, and cost for many industries including electronics, medical, and automotive.

Still, whether it's the best fit depends on your specific application needs. Let's explore why so many of my customers choose CNC aluminum—and when it's not the right answer.

What Are the Key Benefits of Using CNC Aluminum?

You may be struggling with heavy materials, poor surface finishes, or slow lead times. Many engineers hit these pain points during development.

CNC aluminum solves these issues with its high strength-to-weight ratio, fast machining speed, and excellent surface finish, making it perfect for rapid prototyping and production.

Fast Machining = Faster Delivery

Aluminum cuts faster than steel and doesn't require the same heavy-duty tooling. That means quicker prototypes, more flexible iteration cycles, and shorter lead times.

Great Strength-to-Weight Ratio

Here’s a simple table comparing key material properties:

| Material | Density (g/cm3) | Yield Strength (MPa) | Machinability (1-10) |

|---|---|---|---|

| Aluminum 6061 | 2.7 | 276 | 9 |

| Steel 1018 | 7.87 | 370 | 6 |

| Plastic ABS | 1.04 | 40 | 10 |

You can see aluminum is much lighter than steel but still strong enough for most structural parts.

Excellent Surface Finish and Post-Processing

Aluminum supports many finishing options: anodizing, sandblasting, brushing, powder coating, and more. This flexibility is why it's widely used in electronics housings, medical equipment, and consumer products.

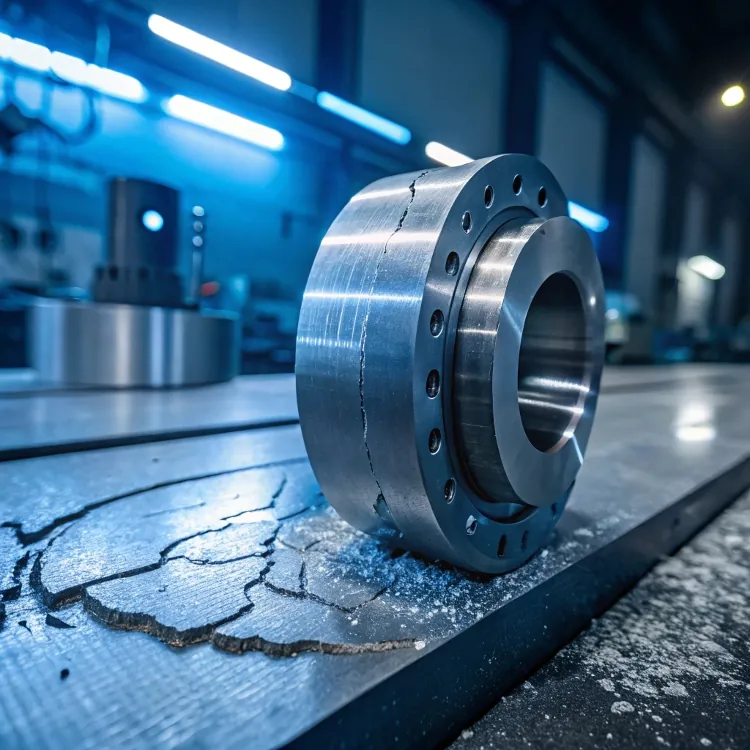

What Drawbacks Should You Consider with CNC Aluminum?

Not everything about aluminum is perfect. Some issues only show up after production begins.

CNC aluminum can deform under high stress, and certain alloys have poor corrosion resistance unless treated, requiring surface finishes.

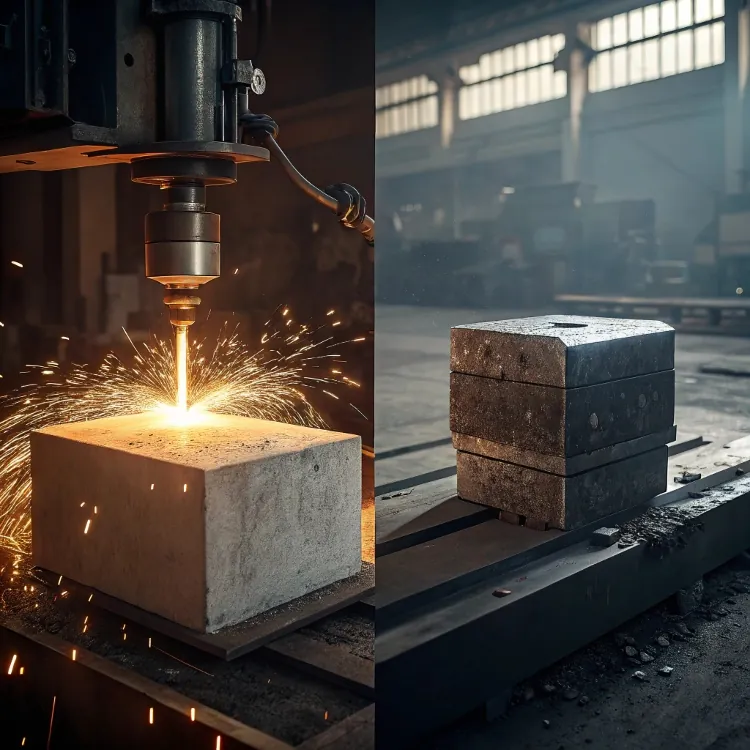

Material Waste and Cost Concerns

Unlike plastic molding or die casting, CNC machining is subtractive. You start with a solid block and cut away. That means more waste material, especially for parts with deep cavities or hollow features.

Thermal Expansion and Deformation

Aluminum expands more than steel when exposed to heat. This could affect applications requiring thermal stability. For example, in high-temperature environments, the dimensional stability of aluminum could cause issues.

Galvanic Corrosion

If you're mating aluminum with stainless steel or carbon steel, be careful. Without proper coating or insulation, galvanic corrosion may occur due to electrical potential differences between metals.

Which Aluminum Alloy Suits Your CNC Project Best?

Choosing the wrong alloy can ruin surface finishes or compromise mechanical performance. I've seen clients rework entire designs due to alloy mismatches.

Aluminum 6061 is the most versatile alloy for CNC projects, but 7075 is preferred when higher strength is required, and 5052 is ideal for corrosion resistance.

Common Alloys at a Glance

| Alloy | Best For | Strength | Corrosion Resistance | Cost |

|---|---|---|---|---|

| 6061 | General-purpose structural parts | Medium | Good | $ |

| 7075 | Aerospace, high-stress components | High | Moderate | $$$ |

| 5052 | Marine, enclosures, brackets | Low | Excellent | $$ |

Application Matching

- Use 6061 if you're making enclosures, brackets, or chassis for devices or tools.

- Choose 7075 if you need lightweight parts with high strength for aerospace or racing applications.

- Select 5052 when corrosion resistance is a top priority, such as in marine hardware.

How Does CNC Aluminum Compare to Steel in Cost and Performance?

You might think steel is the stronger choice. It often is—but it's not always the better one for your project.

CNC aluminum is lighter, easier to machine, and offers faster turnaround than steel, though it trades off on strength and thermal stability.

Weight and Machinability

Aluminum is about one-third the weight of steel. In projects like drones, medical devices, or wearables, every gram matters. Plus, aluminum is easier to cut and drill, saving time and tool wear.

Cost Comparison

Although aluminum material costs may be slightly higher per kilogram, lower machining time often offsets this.

| Comparison Metric | CNC Aluminum | CNC Steel |

|---|---|---|

| Machining Time | Short | Long |

| Tool Wear | Low | High |

| Surface Finish Options | Many | Fewer |

| Post-processing Needs | Often needed | Sometimes |

| Final Part Weight | Light | Heavy |

If you’re designing a lightweight consumer product, aluminum is the better deal. But for industrial frames or mechanical arms under high load, steel still rules.

Conclusion

CNC aluminum is a smart choice for many precision parts thanks to its strength, machinability, and finish options. Still, it's important to pick the right alloy and know when steel is better.