Struggling with traditional cutting methods that wear tools, distort parts, or slow production? That’s the pain point. Discover how CNC laser cutting tackles it with precision and speed.

A CNC laser cutting machine uses computer‑numerical‑control (CNC) to direct a high‑power, focused laser beam along a programmed path, melting or vaporising material to produce high‑precision cuts.

Let’s explore how it works, why it’s worth investing in, which tasks it suits best, and where you’ll find it used in industry.

How does a laser cutting machine operate?

Imagine a beam so focused it slices metal like butter—this is where things get technical and fascinating.

The system starts with CAD/CAM design, converts to G‑code for the CNC controller, then the laser head follows that path, with assist gas and lens focus, to cut the material.

To understand how a CNC laser cutting machine operates, let me break it down step‑by‑step and also discuss key components, process variables and practical considerations.

1. Design & programming

You start with a design in CAD software. Then you use CAM to convert the design into G‑code or similar CNC language. This code guides the machine’s movement. The CNC controller interprets the G‑code and moves the cutting head (or sheet) along the X and Y axes (and sometimes Z for focus adjustment).

2. Laser generation and focusing

A high‑power laser source (for example CO₂ gas laser, or fiber laser) produces a beam. That beam is directed through optics and focused by a lens to a very small spot on the workpiece. The small spot means very high energy density.

3. Cutting process

Once focused, the laser spot heats the material rapidly. In metals, it may melt or vaporise the material; assist gas (oxygen, nitrogen or air) may blow out the molten or vaporised material. The CNC then moves the laser head (or material) following the programmed path, creating a cut.

4. Assist gas & cooling

Assist gases perform several roles: they blow away molten material, may react (oxygen can aid cutting of steel by oxidation), and help keep the kerf clear. Cooling of optics and laser generator is also important because the laser system generates significant heat.

5. Material removal and finishing

As the beam moves, the kerf (the width of cut) is created. Many machines achieve very narrow kerf widths (under 0.1 mm in some cases). After cutting, parts may need inspection and possibly post‑processing (deburring, cleaning), though in many cases finishing is minimal.

6. Types of machine motion

There are different machine configurations:

- Flying optics: the laser head moves over a stationary workpiece.

- Moving table: the workpiece moves under a stationary head.

- Hybrid systems.

Critical parameters and what they affect

| Parameter | Impact on Cut Quality |

|---|---|

| Laser power | Higher power allows faster cutting, thicker material |

| Cutting speed | Too fast = no penetration; too slow = wide heat zone |

| Focus position | Affects kerf width, edge smoothness |

| Assist gas type | Influences cut speed, quality, and oxidation level |

| Material properties | Reflectivity and thickness affect cutting behaviour |

Practical considerations

Choose a machine matched to your material types and thickness. Ventilation and fume extraction are critical. Optics need regular maintenance. Material warping can be avoided with proper speed and power settings.

Why invest in laser cutting equipment?

Investing in equipment always involves risk, cost and benefits—here’s why laser cutting can tilt the balance in your favour.

Laser cutting equipment delivers high precision, minimal tool wear, fast throughput, less material waste and flexibility across many materials and designs—making it a solid investment for many manufacturers.

When evaluating whether to invest in a laser cutting machine, you need to examine the business case and also what to watch out for.

Main advantages

- High precision for intricate shapes and small features

- No need for mechanical tools, meaning less maintenance

- Clean edges with minimal need for post-processing

- Less waste due to narrow kerf and better material nesting

- Works with metals, plastics, composites, wood, and more

Strategic business benefits

Laser cutting supports fast response to custom orders, improves competitiveness, and reduces tooling costs. It’s ideal for small batch production and can reduce lead times significantly.

Trade-offs and considerations

Laser cutters cost more upfront. Running costs include power and maintenance. Certain materials are harder to cut. Safety requirements for fumes and heat must be followed.

Summary of investment factors

| Factor | Consideration |

|---|---|

| Upfront cost | High, but offset by reduced tooling and faster output |

| Versatility | Cuts many materials, especially thin metals |

| Productivity | High speed, good for both prototyping and batches |

| Maintenance | Needs regular checks on optics and cooling |

| Material limitations | Reflective or thick materials require special setup |

Which tasks suit laser cutting machines?

What kinds of jobs should you seriously consider for laser cutting? If you pick wrong types of tasks, you may not get full value.

Laser cutting machines excel at tasks requiring high precision, complex shapes, minimal tooling, and moderate thickness materials—especially where speed, flexibility and fine detail matter.

Laser cutting suits tasks that require clean edges, speed, and flexibility in design.

Tasks laser cutting handles well

- Complex geometries

- Variable production designs

- Thin-to-medium sheet materials

- Precision parts with minimal post-finishing

- Prototypes or small-batch runs

Example use cases

| Task | Why laser works well |

|---|---|

| Intricate metal brackets | Precision, speed, no tooling |

| Custom signage in aluminium | Clean cuts, design flexibility |

| Light chassis parts for electronics | Fast, accurate, minimal warping |

| Short runs of custom machine parts | No tooling cost, fast turnaround |

Less suitable tasks

- Very thick plates (over 25 mm)

- Highly reflective materials (copper, aluminium) without correct setup

- Very basic shapes in high volume (better suited for punching)

- Materials extremely sensitive to heat

Where are laser cutting machines used?

Let’s look at real-world industry sectors where laser cutting machines are employed—and maybe you’ll spot parallels with your business or your clients’ needs.

Industries such as automotive, aerospace, construction, medical, signage, textiles and sheet-metal fabrication use laser cutting machines because they need precision, speed, flexibility and quality.

Laser cutting is widely used in both heavy and light industries.

Common industries using laser cutters

- Automotive: Body panels, chassis, custom brackets

- Aerospace: Lightweight structures, precision components

- Construction: Structural metal parts, façade panels

- Sheet metal fabrication: General components, machine covers

- Medical: Implants, surgical tools, housings

- Signage/Furniture: Decorative panels, branding, artistic cuts

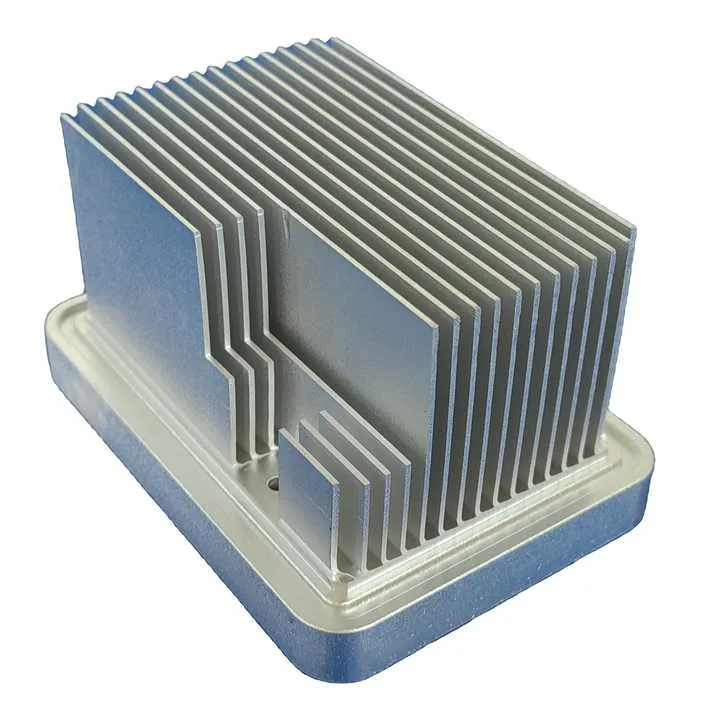

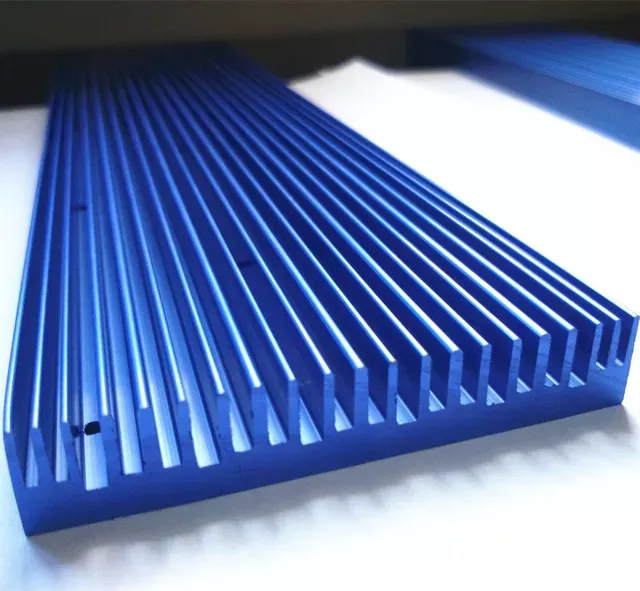

Match with aluminium profile industry

Laser cutting can work with extruded aluminium parts:

- End caps and custom plates

- Decorative façade elements

- Solar panel frames

- Custom cut-outs for hardware mounting

Export market relevance

Your global markets (North America, Europe, Africa, Middle East, Japan) all demand precision, short lead times, and flexibility. Laser cutting supports all of these expectations.

Sector summary

| Industry | Example Use Case | Laser Cutting Benefit |

|---|---|---|

| Automotive | Panels and brackets | Speed, repeatability |

| Aerospace | Lightweight components | Precision, no tooling |

| Construction | Structural base plates | Large format, fast processing |

| Medical | Small, precise tools | Clean cut, tight tolerance |

| Signage/Furniture | Artistic panels, letters | Flexible shapes, clean finish |

| Aluminium Products | End-plates, frames | Matches precision and volume need |

Conclusion

In this article I explained what a CNC laser cutting machine is, how it works, why it’s often a wise investment, which tasks it suits best and where it’s used. If your business involves custom shapes, high precision and diverse materials, laser cutting could enhance your offering and competitiveness.