CNC machining sounds complex. But once you understand milling and turning, and how they work together, it becomes clear why so many industries rely on them.

CNC milling uses spinning tools to shape metal or plastic. CNC turning spins the material itself. These two methods often work together to make strong, detailed, and accurate parts.

If you've ever wondered how modern machines create parts with high precision, this article will explain the key differences, how they complement each other, and why combining them is a game-changer in manufacturing.

How do milling and turning differ?

Many people confuse milling and turning because both involve machines cutting materials. But they operate in opposite ways. Knowing the difference helps you pick the right process for the right job.

In CNC milling, the cutting tool spins while the workpiece stays still. In CNC turning, the workpiece spins and the tool moves. Each method shapes parts in a unique way.

Understanding how each method works is important. Milling uses a tool that rotates at high speed. It removes material from the top, side, or even the inside of a solid block. This allows for complex shapes, holes, and slots.

Turning, on the other hand, rotates the material. A cutting tool touches the surface and removes layers. This is perfect for parts with round shapes, like shafts or rings.

Key Differences Table

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Rotation | Tool rotates | Workpiece rotates |

| Ideal Shape | Flat, irregular, detailed surfaces | Cylindrical or symmetrical shapes |

| Complexity | Good for complex geometries | Best for simple round parts |

| Tool Movement | Moves on multiple axes (X, Y, Z) | Moves mainly along X and Z axes |

| Material Handling | Fixed on a table or bed | Held in a spinning chuck |

Each method has its own use case. Milling is flexible and works on more axes, allowing it to produce a wide range of features. Turning is faster for round parts and usually has shorter cycle times.

Choosing between the two depends on the shape, tolerance, and function of the part. Often, both are used together to save time and increase part precision.

Why combine milling with turning?

It might seem easier to stick to one method. But combining both can actually save time, cut costs, and make better parts. This approach is common in modern CNC shops.

Combining CNC milling and turning reduces setups, increases precision, and handles both round and complex shapes in one machine. This saves time and avoids errors.

Modern CNC machines often come with both turning and milling heads. This hybrid setup is called a mill-turn machine. With it, you don’t need to move the part from one machine to another. The workpiece stays in place, and the machine switches tools automatically.

This means fewer setups. Every time you move a part between machines, you risk small alignment errors. These can cause the final part to be slightly off. But with a single setup, that risk disappears.

Benefits of Combining Both

| Benefit | Explanation |

|---|---|

| Fewer Setups | Part stays on the same machine, reducing human error |

| Faster Production | One machine does all work, reducing transfer time |

| Better Precision | Exact positioning is easier to maintain |

| More Complex Parts | You can cut different shapes without switching machines |

| Cost-Effective | Saves labor and reduces waste from part misalignment |

This is especially useful when parts need tight tolerances. For example, a medical device component that requires a round base and flat milled surface can be done in one go.

It also improves efficiency. A hybrid machine may cost more upfront, but over time, the savings in time and labor are significant. Many high-volume manufacturers now rely on mill-turn systems for this reason.

Which parts need both processes?

Not all parts are simple. Some need round edges and complex surfaces. These parts benefit most from combining milling and turning.

Parts that mix round and flat surfaces, like gears, pulleys, or turbine blades, usually need both milling and turning to be made correctly and efficiently.

Think about a car engine part. It might have a round shaft that must fit tightly inside a bearing. That shape comes from turning. But the same part may also need flat areas for mounting. Those flats come from milling.

Here are some real examples:

Common Parts Requiring Both Processes

| Part Type | Turning Function | Milling Function |

|---|---|---|

| Gear Housing | Turns to shape the outer ring | Mills holes and slots for assembly |

| Turbine Shaft | Turns shaft to exact diameter | Mills blades or grooves |

| Pulley | Turns round body | Mills keyway or bolt holes |

| Valve Body | Turns to fit pipes | Mills mounting surfaces |

| Medical Implant | Turns to form main body | Mills fine detail or textured areas |

These parts must be strong and precise. Using both processes ensures tight fits and smooth finishes.

Also, many aerospace and automotive parts need both turning and milling. Their designs are often compact, with features on every surface. Doing this with one type of machining would be too slow or not accurate enough.

By using both, we can meet tight tolerances. This also avoids the risk of damage when parts are moved between machines. It's all about balance—speed, accuracy, and part quality.

Where are these methods used?

CNC milling and turning are used everywhere—from your smartphone to airplanes. They power modern industries by making reliable, repeatable parts.

CNC milling and turning are widely used in aerospace, automotive, medical, and electronics industries where precision and durability matter most.

Each industry uses these methods in a unique way. But they all need precision and repeatability. These two processes make it possible to produce the same part, again and again, with almost no error.

Industries That Rely on CNC Milling and Turning

| Industry | Example Parts Produced |

|---|---|

| Aerospace | Turbine blades, landing gear, structural supports |

| Automotive | Pistons, crankshafts, transmission parts |

| Medical | Bone implants, surgical instruments, dental components |

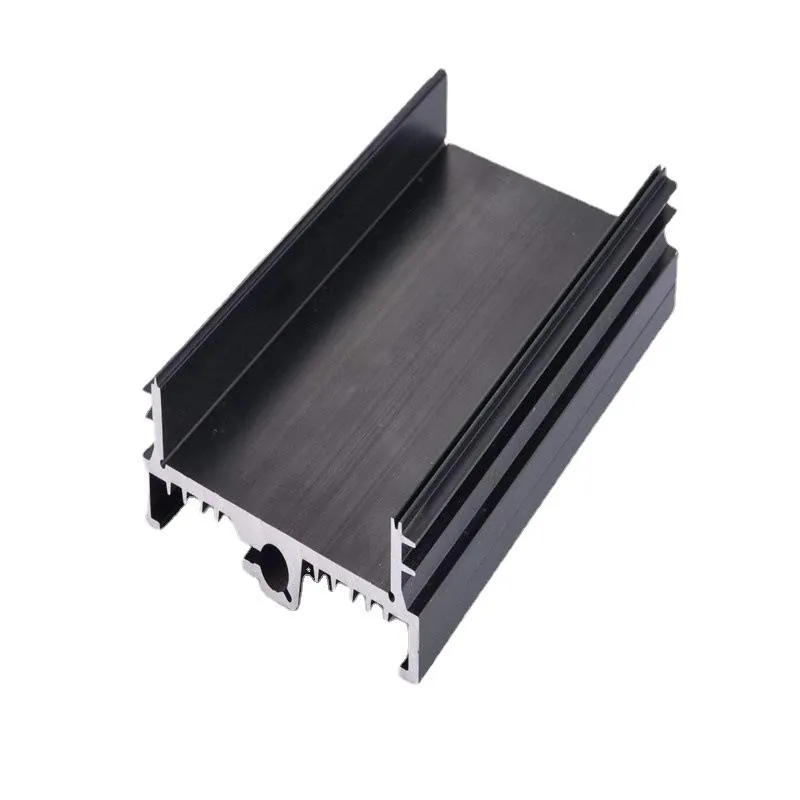

| Electronics | Housings, heat sinks, connectors |

| Robotics | Joints, frames, sensor brackets |

| Defense | Weapon parts, drone frames, vehicle armor fittings |

For example, in the medical field, parts need to be smooth and precise. A joint implant must fit perfectly in the body. Turning gives the part its shape. Milling adds surface texture or screw holes.

In electronics, milling is used to shape flat housings. Turning is used when the housing needs to be round or threaded.

Every day, new machines and tools improve these processes. Automation is increasing, making it easier to go from design to final product in just hours.

Conclusion

CNC milling and turning are essential parts of modern manufacturing. They each serve a different role, but when combined, they can create highly complex and precise parts. Whether for cars, planes, or medical tools, these processes bring ideas into the real world.