Many manufacturers still waste time and material by guessing how to cut. CNC cutting design solves that with digital planning and machine precision.

CNC cutting design is a digital process that creates exact instructions for machines to cut materials like aluminum, steel, or wood. It ensures accuracy, repeatability, and material efficiency.

In this article, I’ll walk you through how CNC cutting design works, where it’s used, and why it’s essential for modern manufacturing.

How is CNC cutting design created?

Most people think CNC just cuts metal, but it’s the design before cutting that truly matters.

CNC cutting design is created using CAD software, nesting tools, and CNC programming to turn technical drawings into machine-readable instructions.

The creation process follows a clear workflow:

Step 1: Start with a Drawing

Every CNC cutting design starts with a 2D or 3D drawing. This may be a sketch from a client or a technical drawing from an engineer. It includes all shapes, sizes, and positions for cuts, slots, and holes.

Step 2: Convert Drawing to Digital Model

Using CAD software (like AutoCAD, SolidWorks, or Fusion 360), the sketch is recreated with exact dimensions. This is where precision begins. Designers add tolerances, part names, and assign layers for different features (cuts, engravings, drill holes).

Step 3: Optimize with Nesting

Next comes nesting. This step places multiple parts on one metal sheet, wood panel, or plastic plate to reduce waste. Nesting software calculates the best way to fit parts together.

Example Nesting Table

| Material Sheet Size | Number of Parts per Sheet | Waste (%) |

|---|---|---|

| 1220mm x 2440mm | 35 | 8% |

| 1500mm x 3000mm | 48 | 4.5% |

Step 4: Generate CNC Code

The design is then converted into G-code using CAM (Computer-Aided Manufacturing) software. This tells the machine what tool to use, how fast to move, where to start and stop.

Step 5: Simulation and Testing

Before real cutting begins, the code is simulated. This catches errors and shows tool paths in motion. Designers fix overlaps or tool collisions here.

Step 6: Send to Machine

Finally, the CNC machine receives the file and cuts the parts exactly as designed. No guessing. No redo.

This process saves time, reduces waste, and guarantees consistent output.

Why use digital design for CNC?

Making things by hand seems flexible—but it’s slow, inconsistent, and hard to repeat.

Digital design gives CNC machines clear, precise instructions, reducing errors, increasing speed, and making mass production possible.

There are several reasons why digital design is essential for CNC:

1. Higher Accuracy

Digital design eliminates human guesswork. Every line and hole is placed by coordinates, not rulers.

2. Better Efficiency

Once a design is finalized, it can be reused or adapted. A new order takes hours, not days.

3. Less Material Waste

With good nesting and simulation, almost every bit of the sheet is used. Mistakes are rare, which saves raw material.

4. Perfect Repeatability

Making 1,000 identical parts? Easy with digital design. Each part is as accurate as the first.

5. Faster Prototyping

Engineers can test a new product by adjusting the design file, not cutting by hand again.

6. Easier Collaboration

Teams can work on the same CAD file, even in different countries. Comments, revisions, and measurements stay visible.

Common CAD File Types

| File Type | Format | Use Case |

|---|---|---|

| .DXF | 2D | Laser and waterjet cutting |

| .DWG | 2D | Architectural and technical drawings |

| .STEP | 3D | Precise mechanical modeling |

| .IGES | 3D | Complex surface and geometry sharing |

For companies like mine that ship parts globally, digital design is non-negotiable. It ensures the factory in China and the buyer in Germany see the exact same thing.

Which projects need CNC patterns?

Some projects can get away with rough cuts. Others can’t afford even 1mm off.

CNC patterns are vital for projects that demand repeatability, detailed shapes, or zero error—such as architectural panels, mechanical parts, or custom aluminum profiles.

Here are project types that benefit the most from CNC patterns:

1. Large Batch Manufacturing

Factories that produce hundreds or thousands of identical items rely on CNC patterns. These could be parts for appliances, tools, or vehicles.

2. Aluminum Frames and Profiles

In construction or solar panel projects, aluminum extrusions need holes or slots in exactly the right place. A CNC pattern ensures all profiles are processed identically.

3. Furniture and Fixtures

In the furniture industry, CNC is used to cut decorative panels, structural supports, and connectors. Even a small miscut can ruin the assembly.

4. Equipment and Machinery Parts

Mechanical parts often have tight tolerances. Patterns help produce slots, holes, or gear interfaces with precision.

5. Signage and Artistic Panels

Designs with curves, lettering, or decorative cutouts need exact patterns. CNC lets you repeat them perfectly, even across large batches.

CNC Pattern Uses Table

| Project Type | CNC Pattern Role | Precision Needed |

|---|---|---|

| Solar Panel Frames | Hole alignment & drilling | High |

| Machinery Housings | Component fitting | Very High |

| Retail Fixtures | Visual alignment | Medium |

| Art Installations | Repeating aesthetic shapes | Medium to High |

| Custom Brackets | Tight bolt-hole tolerance | High |

Whether it’s for aesthetic value or engineering function, CNC patterns bring control to the process. They also help maintain quality across all units.

Where is CNC design applied?

It’s not just for metal shops. CNC design shows up in industries all around you.

CNC design is used in construction, solar energy, machinery, furniture, automotive, and even in decorative metalwork—anywhere accurate cuts are essential.

Here are some examples:

Construction and Architecture

CNC-designed aluminum frames are used for curtain walls, doors, and structural joints. The design ensures perfect fit across different building sections.

Solar Panel Manufacturing

Solar projects require large amounts of identical aluminum support rails. These need slots and holes cut with tight precision. CNC designs keep them uniform.

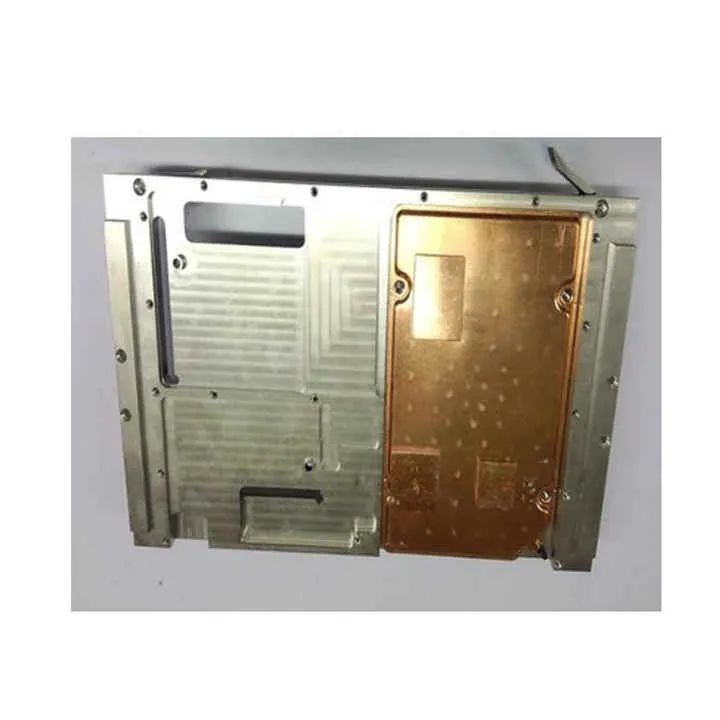

Machinery and Automation

Manufacturing equipment relies on precision. Machine frames, holders, and fixtures all need exact tolerances to function. CNC design helps get them right every time.

Furniture and Interior Design

From custom partitions to metal cabinet frames, furniture brands use CNC designs to create efficient and good-looking parts that fit together cleanly.

Automotive and Aerospace

Precision metal cutting ensures safety and performance. Whether it’s for mounting brackets, support frames, or control panels, CNC cuts it to spec.

Decorative Panels and Art Installations

Designers love CNC for making patterned panels, laser-cut aluminum screens, or branded signage. Repeating those designs by hand would take forever.

Tool and Die Making

Even tools themselves often require CNC-cut inserts, bodies, or holders. Accuracy is non-negotiable in this field.

These applications rely on digital accuracy. Without CNC design, many modern products would simply not fit, function, or look right.

Conclusion

CNC cutting design turns a concept into precision parts. It starts with a digital drawing, then translates into clean, repeatable cuts using CNC machines. From construction to furniture, solar to signs—CNC design keeps modern production sharp, efficient, and reliable.