Manual cutting often leads to mistakes, inconsistent results, and long production times. Many manufacturers face these issues daily. CNC machines solve this by offering speed, precision, and repeatability.

A CNC machine is a computer-controlled tool that automates cutting, drilling, milling, or shaping tasks using programmed instructions. It removes the need for manual adjustments, leading to faster, more accurate production.

Let’s explore how CNC machines work, why they’re better than manual tools, what tasks need their precision, and where they’re used across industries.

How does a CNC machine work?

Many people picture machines that just follow orders. But how do CNC machines really move and cut so accurately?

CNC machines operate using pre-programmed code (G-code) to control movements along multiple axes, guiding the tool to cut materials into desired shapes. These machines follow exact paths with high repeatability.

The basics of CNC operation

CNC stands for “Computer Numerical Control.” A typical CNC setup includes:

| Component | Function |

|---|---|

| Controller | Interprets G-code and sends movement signals |

| Machine bed | Holds the material in place |

| Cutting tool | Rotates or moves to shape the material |

| Axis system | Moves the tool/material in X, Y, Z (and more) directions |

| Software | CAD/CAM programs create and simulate tool paths |

The operator first designs the part using CAD software. Then, CAM software generates the G-code. This code tells the CNC machine how fast to move, how deep to cut, and where to go.

Axis movement and control

Most CNC machines operate on 3 axes:

- X: left and right

- Y: front and back

- Z: up and down

Advanced machines use 4, 5, or 6 axes for complex shapes. These include rotational movements that allow the tool or part to tilt, spin, or angle. This flexibility cuts parts that would otherwise need multiple setups.

Step-by-step process

- Create a CAD model of the part

- Convert the model into G-code using CAM software

- Load the code into the CNC machine

- Mount the raw material

- Start the program — the tool follows the code to cut the part

Each movement is precise, usually down to microns. The process is consistent, so each part comes out the same.

Why choose CNC over manual tools?

Manual machines need constant supervision, skilled labor, and careful hand-control. That leads to slow, inconsistent results.

CNC machines offer higher speed, better accuracy, repeatability, and automation compared to manual machining. They reduce labor costs and allow complex cuts that are hard to do by hand.

Major advantages over manual methods

| Feature | Manual Machine | CNC Machine |

|---|---|---|

| Accuracy | Depends on operator | Controlled by software |

| Speed | Slower | Much faster |

| Complexity | Limited to simple shapes | Handles complex geometries |

| Repeatability | Hard to keep consistent | Perfect repeatability |

| Labor | Needs skilled workers | Can be semi-automated |

| Setup | Requires adjustments per part | Once set, runs automatically |

Reduced human error

With manual work, small hand movements can lead to big mistakes. CNC eliminates this by sticking to the programmed code. The operator only loads material and presses start. The machine does the rest — exactly the same way every time.

Faster production, lower cost

Once programmed, CNC machines can run 24/7. This cuts turnaround time. Also, fewer mistakes mean less scrap and rework. That saves money. While CNC machines cost more upfront, they save more over time through efficiency and lower labor cost.

Complex geometry

Cutting a 3D curve or angled hole by hand is nearly impossible. CNC does it easily. It handles undercuts, contours, and deep features — all from the same setup. That boosts flexibility and capability.

Which tasks require CNC precision?

Not all jobs need advanced machines. But many industries rely on CNC when precision, detail, or complex shapes matter most.

CNC machines are essential for tasks requiring tight tolerances, repeatable output, complex geometry, or fine finishes. This includes aerospace parts, custom tools, and detailed prototypes.

Common CNC tasks

| Task | Why CNC is ideal |

|---|---|

| Milling complex parts | Handles curves, slots, and angled cuts |

| Drilling precise holes | Accurate depth and spacing |

| Cutting patterns in sheet metal | Fast, repeatable shapes |

| Engraving logos or labels | Fine detail and clear results |

| Making dies or molds | High surface finish and tight tolerance |

Key traits of CNC-required jobs

Jobs that benefit from CNC often share these traits:

- High volume: Many identical parts needed

- Fine tolerance: Small error margins

- 3D shape: Surfaces that curve or change angles

- Repeat use: Part must perform the same way every time

- Detailed features: Threads, slots, or channels too fine for manual tools

Examples from real manufacturing

- An automotive supplier needs 5,000 aluminum brackets with tight hole alignment. CNC handles this with no variation.

- A medical device company designs a custom surgical tool with curved handles and finger grooves. CNC mills the part from titanium precisely.

- A custom bike maker wants unique chainrings with fine logo engravings. CNC laser or mill does this perfectly.

These tasks need more than what manual tools or 3‑axis setups can do. They need the consistency, fine motion control, and advanced pathing only CNC offers.

Where are CNC machines used?

Modern manufacturing relies heavily on CNC. You’ll find these machines in shops big and small, across industries and countries.

CNC machines are used in aerospace, automotive, electronics, medical, construction, and general manufacturing to produce accurate parts efficiently. Their ability to handle complexity makes them essential in advanced production.

Key industries using CNC

- Aerospace: Aircraft parts, engine components, brackets. Requires extreme precision and strong materials.

- Automotive: Engine blocks, pistons, gears, custom brackets. CNC ensures fit and finish.

- Medical: Implants, surgical tools, enclosures for devices. Needs high accuracy and biocompatible materials.

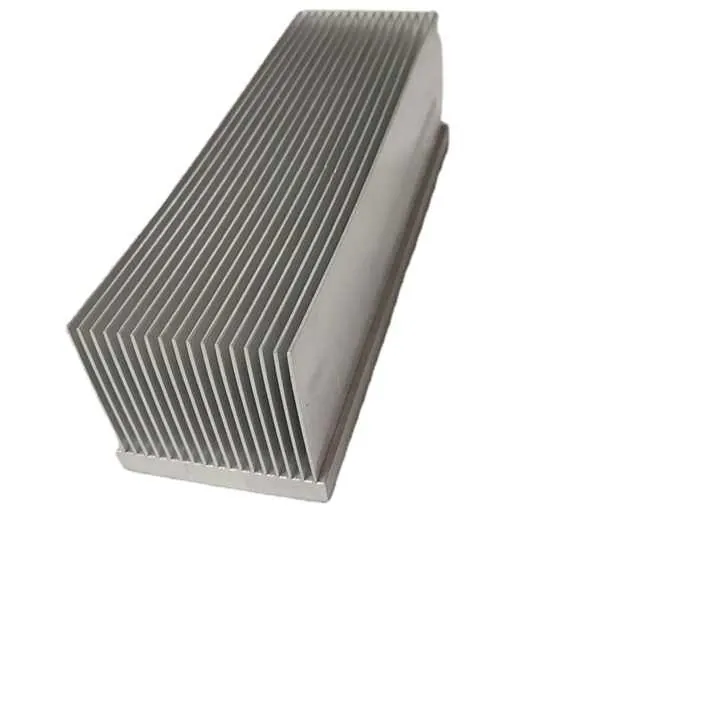

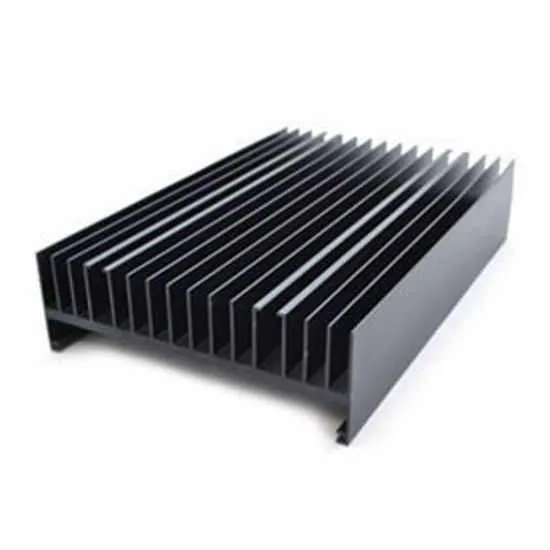

- Electronics: Phone casings, cooling plates, connectors. CNC creates complex housings from aluminum or plastics.

- Tooling & mold: Mold bases, injection dies, press tools. CNC handles complex geometry and fine finishes.

- Construction: Aluminum profiles for facades, brackets, joints. Custom shapes and holes cut cleanly.

Why CNC fits global industry needs

Businesses now ship worldwide. They must keep quality consistent across batches. CNC ensures every part meets specs, no matter where made. It also speeds up delivery by removing manual steps.

In regions like Europe, North America, and East Asia, CNC is essential for competitive production. Emerging markets use CNC to scale quickly and meet global standards.

Whether it’s a single custom job or a run of 10,000 parts, CNC keeps things precise, clean, and fast.

Conclusion

CNC machines transform how we cut, shape, and build. They remove guesswork, lower labor needs, and boost accuracy. From simple drilling to high-end aerospace milling, CNC tools offer repeatable precision. Their role across industries shows their value: speed, flexibility, and control. When accuracy and scale matter, CNC is the answer.