Milling metal by hand often feels slow. Mistakes cost time and materials. CNC milling brings speed, precision, and less waste.

A CNC milling machine is a computer‑controlled tool that removes material from a solid block to shape precise metal (or other materials) parts. It cuts, drills, and carves based on digital designs.

CNC milling changed how parts get made. It makes complex shapes cleanly. It cuts the link between design and final product. Below I explain how it works, why we use CNC, what projects need it, and where it fits best.

How does a milling machine function?

Milling machines cut away material using rotating tools. The machine moves a solid block while a cutter shapes it precisely.

A milling machine works by holding a workpiece and spinning a cutting tool at high speed. The tool moves along multiple axes to remove tiny bits, forming the final shape.

When I think about how a milling machine works, I imagine a block of metal fixed on a table. The table can move forward/backward (Y‑axis) or left/right (X‑axis). Meanwhile a cutting tool spins fast, moving down (Z‑axis) to cut into the metal. By combining these movements, the machine shapes complex parts.

Basic parts and motions

| Component | Function |

|---|---|

| Worktable | Holds the workpiece and moves X/Y |

| Spindle | Holds the cutter and spins it |

| Cutter (end mill) | The cutting tool removing material |

| Axis motors | Drive precise motion on X, Y, Z axes |

| Controller & software | Use design files to guide movements |

As the controller reads a digital design (called a CAD file), it converts instructions into movements. Every small move cuts some metal. The process continues until the shape matches the design. The “chips” or metal dust fall away, leaving the part smooth and exact.

Why multiple axes matter

Older milling machines could only move in two directions. That limited shapes to simple blocks and holes. Modern CNC mills often have 3 axes (X, Y, Z). Some have 4 or 5 axes. These extra axes let the tool tilt or rotate. Then the machine can carve curved surfaces or angled slots in a single setup. This saves time and avoids repositioning the part multiple times.

Speed and precision

CNC machines spin the cutter at high RPM (hundreds to thousands). The motors move the table or cutter in very small steps — often fractions of a millimeter. As a result, one machine can produce many identical parts. Each part has tiny variation, well within tight tolerance. That precision matters for engineering parts, molds, or assemblies with many matching pieces.

Summary of function

The milling machine removes material bit by bit. A digital design tells it where to cut. The machine moves smoothly and fast along axes. The result is an exact shape from a plain block. This method beats manual cutting in speed, repeatability, and complexity.

Why use CNC for milling?

Manual milling works for simple jobs. Yet human error, limited speed, and shape complexity make it weak when parts need fine detail. CNC milling solves these issues.

CNC milling offers accuracy, repeatability, and efficiency. It handles complex designs with minimal error and high speed.

Humans can only move tools so fast and so steadily. For a single custom part, manual milling may suffice. But when you need many parts that match exactly, or shapes with fine details, repeating the same steps by hand often fails. CNC removes this problem. Once you program the design, the machine does identical copies every time.

Benefits of CNC milling over manual methods

- Precision and consistency: CNC can keep accuracy within tenths or even hundredths of a millimeter.

- Efficiency: The machine runs at high speed. It works long hours without fatigue.

- Complex geometry: CNC handles complex shapes, curves, pockets, holes at many angles.

- Repeatability: Every piece in a batch can be identical. That matters for mass production.

- Less labor skill needed: After programming, less manual skill is required to run the machine.

These advantages matter especially if parts are many, complex, or need tight tolerance. Also, CNC reduces waste. Because the machine cuts only what design needs, it eliminates over‑cutting or reworking.

When CNC shines vs when it might be overkill

Manual milling may work for one‑off prototypes or simple blocks. CNC often proves too expensive or unnecessary for tiny, simple jobs. But once you need many pieces, or precision beyond human ability, CNC wins.

| Scenario | Use CNC milling? |

|---|---|

| Simple block with few holes | Not necessary |

| Single custom prototype part | Possibly manual |

| Batch of identical parts | Yes |

| Complex curved or angled surfaces | Yes |

| Tight tolerance requirement | Yes |

Overall, CNC milling offers a powerful mix of speed, precision, and flexibility. That is why many industries adopted it.

Which projects need CNC milling?

Some projects need only simple cuts. Others need strong, exact, complex parts. Projects that demand precision, volume, or complexity often need CNC milling.

Projects needing tight tolerances, repeatability, and complex shapes will benefit most from CNC milling. These include batch manufacturing, precise metal parts, molds, and prototypes.

Selecting CNC milling depends on project scale and precision needs. For instance, if a project needs a single block with a rough shape for testing, manual methods may work. But for a batch of 100 metal brackets with exact hole placement and alignment, CNC is far better.

Examples of projects suited for CNC milling

| Project Type | Why CNC helps |

|---|---|

| Engine parts for machines | Need precision and strength |

| Custom metal brackets or frames | Require exact hole positions and alignment |

| Prototypes for new designs | Need speed and accuracy |

| Molds and dies for casting | Need perfect geometry and repeatability |

| Complex metal enclosures or parts | CNC shapes complex curves or angles easily |

When CNC milling is most cost‑effective

CNC milling becomes cost‑effective when:

- the job involves many identical parts;

- the parts have tight tolerance;

- shapes are complex or curved;

- you need consistent quality across all units;

- you want faster production than manual methods allow.

When a project meets one or more of these points, CNC milling not only speeds up work, but also saves cost in the long run.

I remember a time when our factory considered making a simple aluminum clamp by hand. We tested manual milling for one or two pieces. It worked but each piece differed slightly. Then we switched to CNC. The first batch of 200 units came out almost identical. That consistency saved us time, reduced waste, and avoided quality complaints.

Using CNC for a project is a decision about volume, quality, and long‑term efficiency. If a project expects repeat orders or needs stable output, CNC milling is often right.

Where is CNC milling applied?

CNC milling shows up in many industries. It builds parts for machines, vehicles, tools, and even consumer goods. Its reach is wide and growing.

CNC milling finds use in industries from automotive and aerospace to furniture and solar frames. Wherever precise metal parts are needed, CNC often helps.

Many sectors rely on CNC milling. For example, in automotive, engine blocks, transmission parts, brackets, and customized components come from CNC mills. Aerospace parts use CNC because they need high precision and strong, lightweight material.

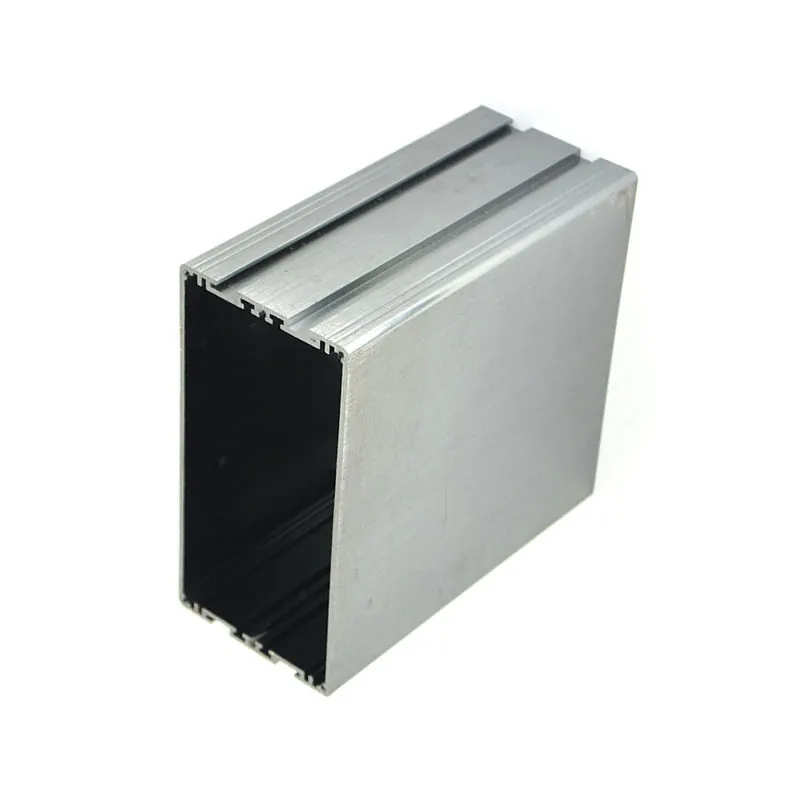

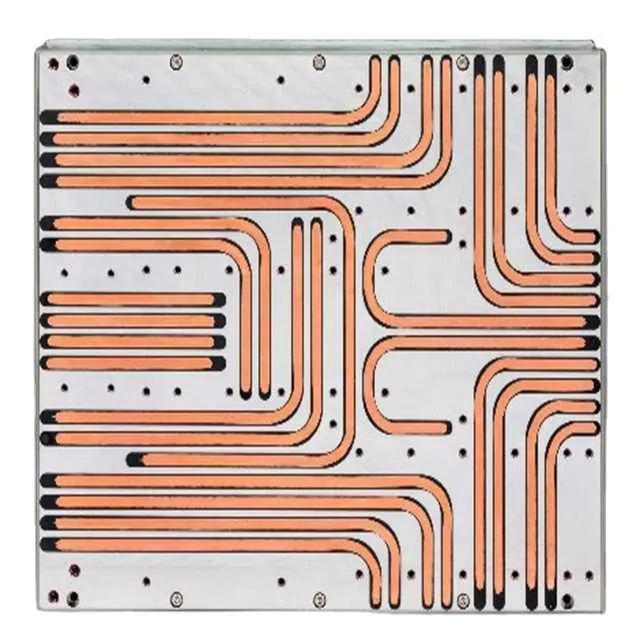

In architecture and construction, CNC helps cut aluminum frames, complex joints, and mounting hardware. Furniture firms sometimes use CNC to shape metal parts like legs or frames. In electronics, CNC cuts enclosures, heat sinks, and components with tight tolerance. Medical equipment and tools often require accurate parts — CNC delivers.

Broad areas of application

- Automotive and aerospace: Engine parts, structural components, housings.

- Industrial machinery: Gears, shafts, frames, custom fittings.

- Construction and architecture: Metal frameworks, window/door frames, architectural fittings.

- Furniture & lighting industry: Metal legs, supports, custom casings.

- Electronics and consumer goods: Enclosures, heat sinks, custom parts.

- Molds and tooling: Molds for casting, dies for pressing, injection molds.

Why CNC works across many sectors

CNC milling uses materials like aluminum, steel, brass, plastics, and more. That flexibility makes it suitable for many fields. The precision ensures parts fit and operate well. The speed and repeatability help meet large orders. Customization also becomes easier — changing a CAD file changes all parts.

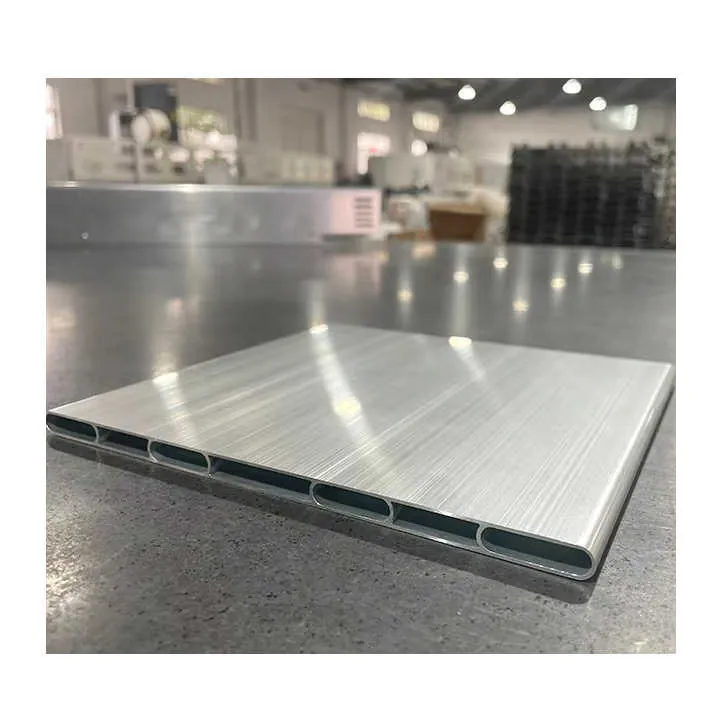

In sectors like solar energy, aluminum frames for solar panels often need exact dimensions. CNC milling helps produce them quickly and with uniform quality. In lighting manufacturing, aluminum heatsinks and housings benefit from CNC precision and surface finish.

When non‑metal materials are used

CNC milling is not limited to metal. It can also work with plastics, wood, composites, and others. For example, furniture makers use CNC to shape wooden legs or veneer parts. Designers use CNC to cut plastic prototypes quickly. That makes CNC useful beyond heavy industry.

Using CNC milling doesn’t always mean production of metal parts. Sometimes it supports testing, prototyping, or small‑batch production. That versatility helps many industries.

Conclusion

CNC milling machines turn digital designs into real parts with speed and precision. They work well when projects need accuracy, repeatability, or complex shapes. That makes CNC milling a key tool across many industries.