Modern manufacturing always asks: are Chinese CNC machines any good? Many buyers worry about quality and reliability when they see low prices for CNC from China.

Chinese CNC machines can deliver good performance for many tasks. Their quality depends on brand and build. In many cases they match international standards while offering lower cost.

Keep reading to see how Chinese CNC machines stack up around the world, why they cost less, who uses them, and what affects their reliability.

How do Chinese CNC machines compare internationally?

Many people expect big differences when they compare Chinese CNC machines with Western or Japanese ones.

Chinese CNC machines often offer similar basic functions as international brands. Their accuracy and features can be adequate for many factories.

Comparing features and cost

| Feature / Attribute | Typical Chinese CNC Machine | Typical Western / Japanese CNC Machine |

|---|---|---|

| Basic machining accuracy | ±0.05–0.1 mm (for mid-range models) | ±0.01–0.05 mm (top-grade models) |

| Components (spindle, drives) | Mix of local + some imported parts | Premium global-brand components |

| Control software | Standard G-code, some custom OS | Advanced proprietary systems |

| Price (for similar size) | 40%–60% lower cost | Higher cost due to premium parts |

| After-sales / support network | Growing, but uneven globally | Strong global support, wide network |

The table shows that Chinese CNC machines often deliver reasonable machining accuracy and good base functions. Their main weakness appears in premium-grade precision and long-term support. However, for many applications, their accuracy is “good enough”. The lower price makes them a serious choice for budget-conscious manufacturers.

Chinese machines increasingly adopt some imported parts. Some models even match the lower end of international machines. For basic and mid-level work the gap can be small.

Also Chinese makers often design for flexibility. They produce both standard and custom machines. For firms needing standard shapes or simple parts, performance is acceptable. For complex or ultra-precise parts, Western machines may still hold advantage.

In global markets, many users buy Chinese CNC for initial capacity expansion. Then later, they may invest in premium CNCs. That shows Chinese CNCs can serve as a stepping stone without heavy capital burden.

Thus globally Chinese CNC machines sit in a middle ground: not always as precise or durable as top brands, but often capable for many real tasks — especially when budget matters.

Why are Chinese CNC systems cost-competitive?

Low cost often looks too good to be true. Many buyers wonder why Chinese CNC machines cost much less than Western ones.

Chinese CNC makers benefit from cheaper labor, local supply chains, and large-scale production. They cut cost in many ways without always cutting basic functionality.

Often Chinese factories buy aluminum profiles, steel, electronic parts from local or regional suppliers. Labor cost is lower than in Europe or North America. Over many machines, these savings add up.

Large domestic demand inside China also helps reduce cost per unit. Many factories buy CNCs at once. That gives Chinese makers economies of scale. They pass savings to overseas buyers.

Local supply chains also shorten shipping and import costs for components. That reduces total production cost.

Chinese CNC manufacturers often simplify machine design. They choose simpler control systems and standard parts. That lowers cost further. Simplified design reduces maintenance parts cost too.

Many machines target emerging markets or budget-savvy buyers. These buyers accept lower precision or simpler features. They prioritize cost over premium features.

Because of these factors, Chinese CNC systems often cost 40–60% less than comparable foreign machines. For many buyers, the savings outweigh potential trade‑offs.

When a business needs to control costs, Chinese CNC offers a low-barrier entry to expand production quickly. That makes them attractive for small factories or startups.

Which industries adopt China-made CNC machines?

Many sectors around the world already use CNC machines made in China. The range is diverse, from furniture to solar to industrial parts.

Industries such as furniture manufacturing, aluminum framing for construction, lighting fixtures, solar‑panel frames, standard metal parts, and general fabrication often use China‑made CNC machines.

Industries and use cases

| Industry / Sector | Common CNC Uses | Why Choose Chinese CNC |

|---|---|---|

| Furniture & wood‑metal work | Cutting, shaping, drilling frames | Lower cost fits tight margins |

| Aluminum framing / construction | Cutting and shaping aluminum profiles | Good for standard sizes, keeps cost down |

| Lighting fixtures & metal art | Small batch cutting and shaping | Affordable for medium precision needed |

| Solar panel frame production | Extrusion trimming, drilling mounting holes | High volume demand, cost control is vital |

| General metal parts fabrication | Simple parts, batch fabrication | Cost-effective for standard parts |

Many light‑to‑medium manufacturing operations adopt Chinese CNC to keep cost low. For example, factories making aluminum window frames or standard profiles find Chinese CNC sufficient.

Small to mid-sized furniture makers often need flexible equipment but can’t spend too much. Chinese CNC gives them control and flexibility.

In solar frame production and lighting fixture manufacturing, demand is high but margins can be tight. Lower-cost CNC machines help maintain profit margins without sacrificing too much quality.

In general metal parts fabrication — standard brackets, frames, supports — buyers do not always need very tight tolerances. Chinese CNC works well for these tasks.

Thus China‑made CNC machines find their place in industries where volume or cost matters more than ultra-high precision.

What factors influence Chinese CNC reliability?

When people ask “are they any good”, reliability is often the biggest concern. Chinese CNC reliability varies a lot across makers and models.

Quality depends on brand reputation, component sourcing, manufacturing standards, and maintenance practices. Cheaper machines with unknown parts may perform poorly. Trusted makers with good QC deliver more stable results.

What affects reliability

Component quality

Machines built with high‑quality spindles, motors, drives, and good wiring tend to last longer. Lower cost machines may use cheaper parts. Those can fail more easily over time.

Manufacturing process and quality control

Factories that follow strict manufacturing protocols and inspection before shipment produce more reliable CNC machines. Those that skip tests may ship defective units.

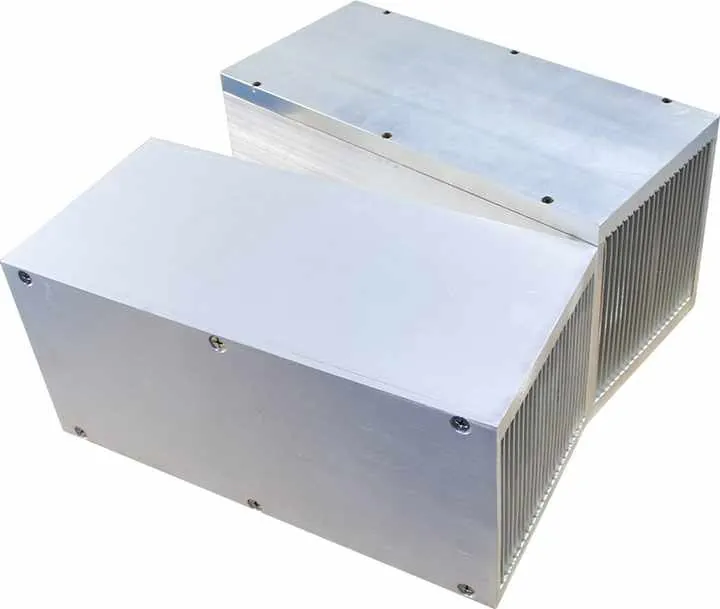

Surface treatment and materials (frame, bed)

Stainless, thick-walled frames resist warping and last longer. Thin or poorly treated frames can deform under heavy load or with time.

Service and maintenance culture

Even a good CNC needs regular maintenance. If operators ignore maintenance, any machine will degrade. Users should follow maintenance schedule: lubrication, cleaning, calibration.

Use case and workload

Heavy industrial use, 24/7 operation, or cutting hard metals stress the machine. For frequent heavy workload, only well-built machines with spare parts support survive.

Environment and setup

Workshop conditions — humidity, dust, temperature — affect machine life. Poor electrical conditions or unstable power also harm control boards and motors.

How to improve reliability when buying Chinese CNC

- Choose machines with known brand or good track record.

- Ask for parts list and origin. Prefer machines with quality spindles, standard drives, and good wiring.

- Ask for testing reports, QC certifications, or demo runs.

- Plan maintenance: regular cleaning, lubrication, alignment checks.

- Use stable electricity supply, clean workshop, proper grounding.

- Use machines within their design limits. Avoid pushing low‑end machines for tasks they aren’t meant for.

When buyers follow these guidelines, Chinese CNC machines can give reliable service comparable to more expensive machines. The difference comes from care in selection, setup, and maintenance — not just price.

Conclusion

Chinese CNC machines can be good choices when budget matters and tasks fit their capabilities. Their value appears when buyers choose wisely, maintain properly, and match machines to realistic needs.