Making parts by hand takes time and often leads to mistakes. But CNC machines changed everything—bringing speed, control, and repeatability to modern manufacturing.

A CNC machine is a computer-controlled device that automates the movement of cutting tools to shape materials like metal, plastic, or wood with precision and consistency.

Today, CNC machines are the foundation of factories, workshops, and even hobby garages. They’re used to create parts for everything from cars to furniture. Let’s look at how they work and why they’re so widely used.

How does a CNC machine operate?

Before CNC, machinists turned wheels and levers by hand. Now, those actions are automated with computers and code.

A CNC machine operates by interpreting a digital design file and using motors to control tools that cut or shape the material step by step, following exact instructions.

CNC stands for “Computer Numerical Control.” This means the machine receives instructions in the form of numerical code—usually G-code—that tells it exactly how to move.

Main Workflow of a CNC Machine:

- Design – A part is drawn using CAD (Computer-Aided Design) software

- Programming – The design is converted into G-code using CAM software

- Machine Setup – Material and tools are loaded into the machine

- Operation – The CNC executes the program, shaping the material

- Finishing – Parts are cleaned, checked, and packaged

Key Components of a CNC Machine:

| Component | Function |

|---|---|

| Controller Unit | Reads code and sends commands to machine |

| Drive Motors | Move machine parts with high precision |

| Tooling System | Holds and changes the cutting tools |

| Workholding Devices | Secure the raw material in place |

| Feedback System | Monitors position and corrects errors |

CNC machines can move in multiple directions, often called axes:

- 3-axis: Moves up/down, left/right, and forward/backward

- 4-axis: Adds rotation around one axis

- 5-axis: Rotates the part or tool in multiple directions

This allows CNC machines to make very detailed and complex parts that would be impossible to make by hand.

Why are CNC machines important?

Modern industries demand speed, accuracy, and cost control. Manual processes can't keep up—but CNC machines can.

CNC machines are important because they automate part production, reduce errors, increase efficiency, and enable mass manufacturing of complex and high-precision components.

CNC technology doesn’t just make things faster. It makes them better. Every part can be made to the same exact standard. That’s vital in industries like aerospace, where one tiny flaw could mean failure.

Benefits of CNC Machines:

| Advantage | Description |

|---|---|

| Precision | Achieves tight tolerances, often within microns |

| Consistency | Every part comes out the same |

| Efficiency | Runs 24/7 with minimal supervision |

| Flexibility | Easily switch between part designs |

| Safety | Operators don’t need to touch moving tools |

In addition to producing parts, CNC machines also save time on setup. Tool changes, path calculations, and cutting speeds are all pre-programmed.

They also help lower waste. With smart nesting algorithms and optimized tool paths, more material gets used and less ends up in the scrap bin.

CNC vs Traditional Methods

| Feature | CNC Machine | Manual Method |

|---|---|---|

| Speed | ✅ Fast | ⚠ Slow |

| Repeatability | ✅ High | ⚠ Depends on operator |

| Complexity | ✅ Very High | ⚠ Limited |

| Scalability | ✅ Easy to scale | ⚠ Difficult |

| Cost Over Time | ✅ Efficient | ⚠ Labor-intensive |

These advantages make CNC machines essential in competitive industries, where timelines are tight and quality can’t be compromised.

Which tasks require CNC precision?

Some parts are too small or complex for human hands. That’s where CNC precision really shines.

Tasks that require CNC precision include mold making, gear cutting, engine part production, surgical tools, and aerospace components—where accuracy is critical.

Precision means more than just small numbers. It means exact fit, tight seals, balanced weight, and flawless symmetry. These qualities matter in both tiny and large parts.

Common High-Precision Tasks:

| Task | Why CNC Is Essential |

|---|---|

| Mold Making | Complex 3D forms and fine details |

| Gear Manufacturing | Requires exact tooth profiles and alignment |

| Medical Implants | Must match body perfectly and meet regulations |

| Engine Components | High heat and stress demand tight tolerances |

| Watchmaking | Microscopic gears and decorative patterns |

Precision Needs by Industry:

| Industry | Precision Application |

|---|---|

| Aerospace | Turbine blades, fasteners, control parts |

| Automotive | Pistons, housings, mounts |

| Medical | Titanium implants, scalpels |

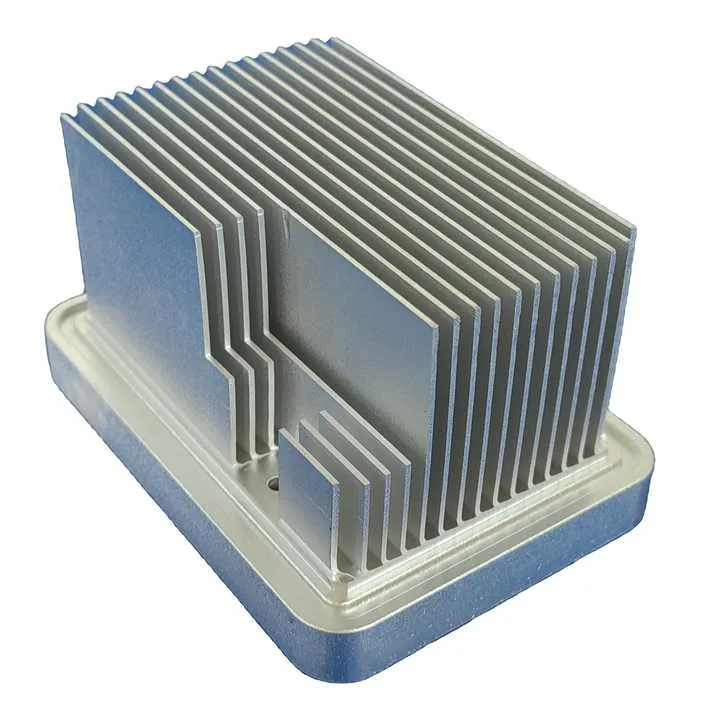

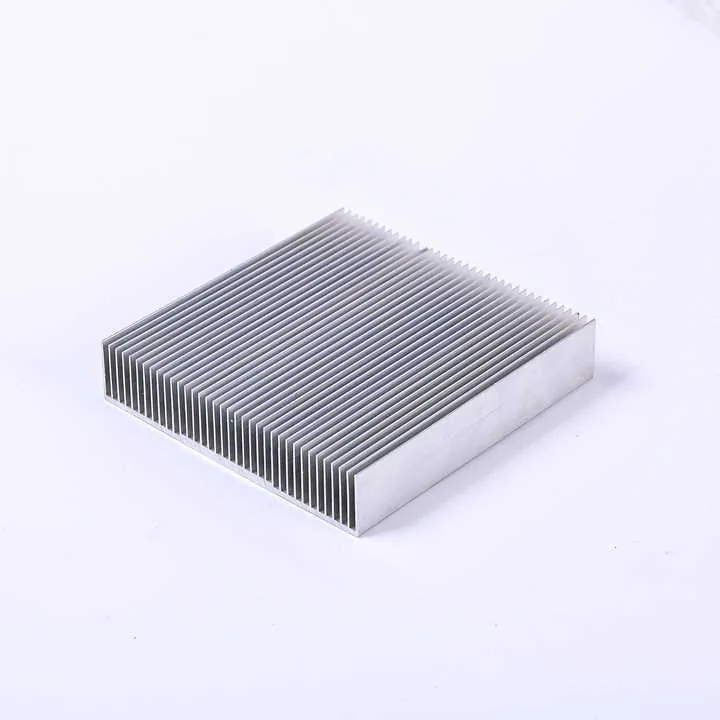

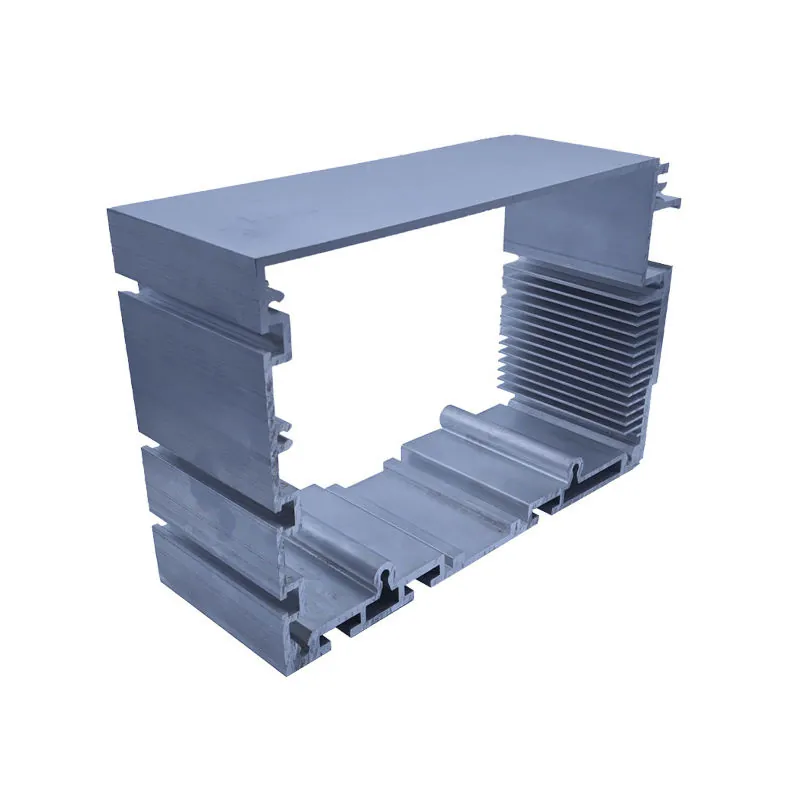

| Electronics | Heat sinks, micro-device enclosures |

| Optics | Lens mounts, micro-adjustment screws |

CNC machines can cut metals, plastics, and composites to specifications that are hard to measure without advanced tools. Some CNC machines use feedback systems like laser sensors to correct tool paths in real-time.

When the margin for error is almost zero, CNC technology is the solution.

Where are CNC machines used?

You’ll find CNC machines anywhere that parts are made. That includes factories, labs, schools, and even small garages.

CNC machines are used in sectors like aerospace, defense, automotive, consumer goods, and energy for manufacturing parts, tools, prototypes, and final products.

They are used for one-off custom jobs, rapid prototyping, and full production runs. And they aren’t just for big companies. Many small shops use CNC to compete globally.

Industries Using CNC Machines:

| Industry | Common Uses |

|---|---|

| Aerospace | Aircraft brackets, landing gear parts |

| Defense | Firearm parts, armor plating, drones |

| Automotive | Engine blocks, gearboxes, chassis components |

| Consumer Products | Knives, metal frames, decorative panels |

| Renewable Energy | Wind turbine parts, solar frame brackets |

Real-World Applications:

- In construction, CNC machines make window frames, curtain wall components, and structural joints.

- In electronics, they produce enclosures, brackets, and heat sinks with tiny features.

- In education, CNC is taught to train students for engineering and product design.

From stainless steel screws to aluminum laptop frames, CNC machines shape the modern world. Even signs, furniture, and art installations rely on this technology to deliver perfect finishes.

Conclusion

CNC machines changed the way we make things. They bring speed, accuracy, and efficiency to tasks that once took hours. From tiny gadgets to big aircraft parts, CNC machines are the hidden engines behind modern manufacturing.