3-axis machining works for most parts—but what if the part has holes on the side, or needs rotation during cutting? That’s where 4-axis CNC machines step in.

A 4-axis CNC machine is a computer-controlled milling machine that adds a rotational axis (usually around the X-axis), allowing more complex shapes and multi-side machining without repositioning the part.

This extra axis unlocks new capabilities. Let’s dive into how it works, what it can do, and why it’s important in advanced manufacturing.

How does a 4-axis CNC machine work?

Traditional machines move up, down, left, and right. But sometimes, that's not enough to reach all sides of a part. 4-axis machining solves this.

A 4-axis CNC machine operates like a standard 3-axis machine, but adds a rotary axis—typically called the A-axis—that rotates the workpiece to allow access to multiple sides.

This extra movement opens new options. Instead of removing the part and rotating it by hand, the machine spins it during the process.

Motion Breakdown:

| Axis | Direction | Description |

|---|---|---|

| X-axis | Left to right | Horizontal movement of cutting tool |

| Y-axis | Front to back | Depth positioning of the tool |

| Z-axis | Up and down | Tool height control |

| A-axis | Rotation around X-axis | Spins the workpiece for side machining |

4-axis machining can be done in two ways:

- Indexing (or positional): The rotary axis turns, then locks in place before cutting begins

- Continuous (or simultaneous): The rotary axis moves during cutting for complex geometries

In continuous 4-axis mode, the tool can mill around a cylinder, engrave curved surfaces, or cut features on multiple faces in one setup.

This eliminates the need to manually reposition the part between operations, which improves accuracy and reduces cycle time.

Why use 4-axis over 3-axis?

3-axis machines are reliable—but they have limits. As parts get more complex, switching to 4-axis unlocks serious advantages.

A 4-axis CNC machine is better than a 3-axis machine when parts require side features, angled cuts, or machining on multiple surfaces without repositioning the part manually.

With a 3-axis setup, all cuts happen from above. If you need to machine a hole on the side, you’d have to stop the machine, remove the part, flip it, and realign. Each step adds time and potential for error.

With 4-axis, the machine does all of that automatically.

Comparison Table:

| Feature | 3-Axis CNC | 4-Axis CNC |

|---|---|---|

| Tool Movement | X, Y, Z axes | X, Y, Z + A-axis (rotational) |

| Setup Changes | Manual repositioning | Automatic rotation |

| Multi-Face Machining | Requires multiple steps | Can be done in one operation |

| Complex Geometry | Limited | Supports angled and side features |

| Precision | Lower with manual setup | Higher with automatic rotation |

Key Benefits of 4-Axis:

- Cuts all sides of a part in one setup

- Reduces downtime from manual repositioning

- Improves overall part accuracy and surface finish

- Shortens cycle times, increases productivity

- Enables new part designs not possible with 3-axis

For example, imagine machining a propeller blade, a camshaft, or a spiral groove. With a 3-axis machine, this is hard or even impossible. With 4-axis, it becomes standard.

Which parts require 4-axis machining?

Some parts can’t be made properly without rotating them. If it has side holes, curved grooves, or multiple faces—it’s probably a job for 4-axis.

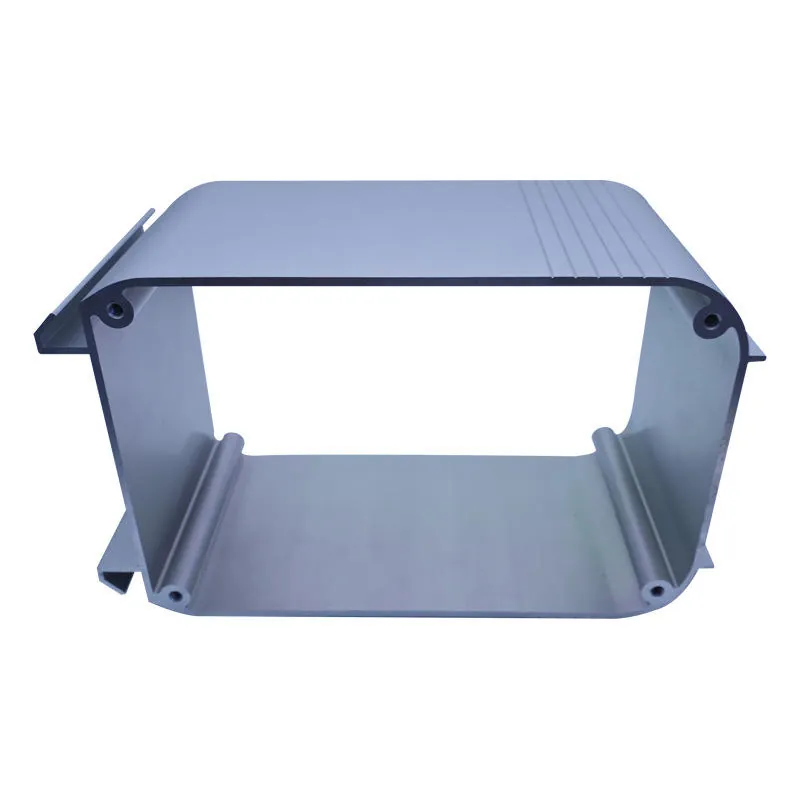

Parts that require 4-axis machining include those with side holes, slots, engravings on curved surfaces, or any features that wrap around a cylindrical body.

When parts must be machined on multiple sides, or involve round profiles, 4-axis saves time and increases precision.

Examples of 4-Axis Machined Parts:

| Part Type | Application Area |

|---|---|

| Camshaft | Automotive engines, needs curved grooves |

| Turbine blade | Aerospace and energy sectors |

| Flanged shafts | Pumps, gearboxes, motors |

| Round heat sinks | Electronics, LED lighting |

| Threaded pipe fittings | Oil and gas, plumbing, fluid systems |

| Decorative columns | Furniture, architectural design |

These parts often require:

- Holes at 90° angles

- Precision alignment between faces

- Uniform spacing around a cylinder

- Smooth transitions from one side to another

4-axis makes these features possible without extra fixturing or manual flipping.

It also supports light engraving on curved surfaces—ideal for logos or part numbers on cylindrical components.

Where are 4-axis CNC machines used?

As products become more complex, 4-axis machining finds its way into more industries. It’s now a must-have in modern manufacturing.

4-axis CNC machines are used in aerospace, automotive, defense, medical, and consumer industries where parts require complex geometries and multi-surface machining.

Wherever you need fast, accurate, and repeatable machining on multiple faces—4-axis fits.

Industry Applications:

| Industry | 4-Axis Machining Applications |

|---|---|

| Aerospace | Impellers, brackets, structural connectors |

| Automotive | Engine cams, transmission parts, axles |

| Defense | Weapon mounts, optical systems, sensors |

| Medical | Surgical tools, implants with contoured shapes |

| Consumer Goods | Bicycle components, camera mounts, tool parts |

Shop Use Cases:

- Prototyping – Machining all faces quickly for testing

- Short-Run Production – Reduces cost per part by saving time

- Engraving – On curved surfaces for branding or traceability

- Tooling – Making complex dies, molds, or fixtures

Even small job shops are adopting 4-axis CNC to stay competitive. It opens the door to new clients and higher-value jobs.

Conclusion

A 4-axis CNC machine adds a powerful rotary feature to standard milling, allowing faster, more precise machining of complex, multi-surface parts. Whether for one-off prototyping or high-volume production, it’s a valuable upgrade that delivers accuracy, flexibility, and competitive advantage.