Sometimes sheet metal just won’t bend the way it should. Projects delay. Costs rise. Frustration builds.

A CNC press brake machine is a computer-controlled tool used to bend sheet metal with high precision, consistent angles, and repeatable quality, even on complex profiles.

Manual machines can be slow and error-prone. But CNC press brakes remove guesswork. They automate precision bending. That’s why modern manufacturers depend on them for efficiency.

How does a CNC press brake operate?

Many think bending metal is all muscle. In truth, it’s more about smart control and precision programming.

A CNC press brake uses a programmable system to control ram motion and back gauge positioning, automating metal bending with accuracy and repeatability.

A CNC press brake works by applying force to a metal sheet placed between a punch and a die. The force comes from hydraulic or electric actuators. The operator inputs the bending angle, position, and sequence through a digital control panel. The machine then calculates how to position the tools and apply pressure to form the desired shape.

Key Components of a CNC Press Brake

| Component | Function |

|---|---|

| Ram | Moves vertically to apply bending force |

| Punch & Die | Shape the metal during bending |

| Back Gauge | Positions the metal accurately |

| CNC Controller | Stores and executes bending programs |

| Foot Pedal | Controls machine activation by operator |

Step-by-Step Process

- Operator selects or inputs bending program

- Sheet metal is placed and aligned using the back gauge

- Press brake lowers the punch onto the metal

- Pressure bends the sheet into the desired angle

- Machine retracts automatically

- Repeat if multiple bends are required

This automation reduces human error. It also saves time on adjustments. Some systems even simulate bends before operation, helping operators preview outcomes and avoid mistakes.

Why use CNC press brakes for bending?

Traditional bending is often inconsistent. Angles vary. Errors multiply with volume.

CNC press brakes offer fast, consistent, and high-precision metal bending, ideal for complex shapes and high-volume production runs.

A CNC press brake bends faster than a manual machine. It can store many programs, each optimized for different materials, thicknesses, and shapes. That means setup is quicker. The output is more consistent, even for large batches.

Benefits of CNC Press Brakes

| Advantage | Description |

|---|---|

| Accuracy | Bending tolerance often within ±0.1 mm |

| Repeatability | Delivers same results across thousands of parts |

| Versatility | Handles various materials and thicknesses |

| Reduced Waste | Fewer errors mean less scrap |

| Time Savings | Faster setup and bending cycles |

| Lower Skill Barrier | Easier for new operators to learn and use |

Flexibility in Custom Projects

This is especially important when bending custom aluminum profiles. Different alloys bend differently. A CNC system can adjust for this automatically. It applies the correct pressure and angle each time.

In our production, CNC press brakes help us form intricate solar frame sections, architectural trims, and LED housing structures. Without this technology, we couldn’t guarantee fit and finish at the required volume.

Which industries depend on press brakes?

Not every product starts flat. But many begin with a sheet.

Industries like automotive, construction, aerospace, and electronics rely on press brakes to form precise metal parts from aluminum, steel, and other materials.

Press brakes serve as a backbone for many sectors. They transform raw sheets into functional components used in everything from airplanes to solar panels.

Industry Applications

Automotive

- Car body panels

- Chassis components

- Brackets and mounting parts

Construction

- Building facades

- Window and door frames

- HVAC ducting

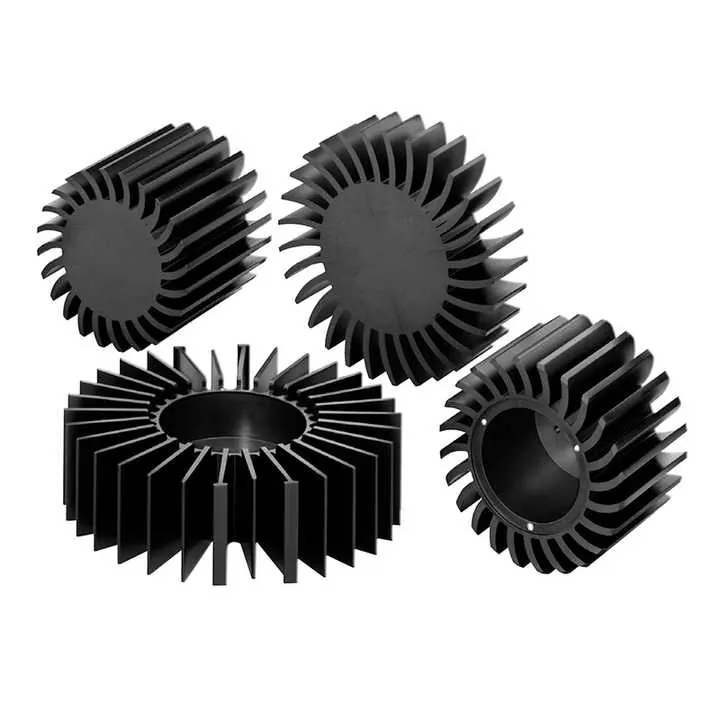

Electronics

- Enclosures for devices

- Aluminum heat sinks

- Server racks

Renewable Energy

- Solar panel frames

- Mounting rails

- Wind turbine housing parts

Why These Sectors Rely on CNC

Each of these sectors demands accuracy, speed, and cost efficiency. CNC press brakes meet those needs. They support lean manufacturing. They reduce manual labor. And they deliver consistent quality, part after part.

We’ve seen this in our cooperation with solar companies across Europe. They need large aluminum extrusions bent with tight tolerances. CNC technology makes this possible.

Where do CNC press brakes improve accuracy?

Accuracy isn’t just about numbers—it’s about performance in real-world use.

CNC press brakes improve accuracy in angle control, part positioning, and repeatable quality, even when working with varying material types or thicknesses.

A key area of improvement is angle accuracy. Manual machines often produce angles that vary due to human error or material inconsistencies. CNC systems compensate for material spring-back and adjust force automatically.

How Accuracy Is Achieved

1. Real-time Monitoring

Sensors track ram position, pressure, and back gauge alignment. Feedback loops adjust parameters during bending.

2. Dynamic Compensation

CNC controllers adjust pressure or stroke to account for:

- Material thickness variation

- Alloy properties

- Temperature effects

3. Intelligent Bending Software

Some systems come with offline simulation tools. These help optimize bending sequences, avoiding collisions or deformities.

Use Case: Thin-Wall Extrusions

Thin-walled aluminum can deform easily. Manual bending often causes cracks or uneven angles. Our CNC press brakes apply the precise force curve required. This ensures consistent bends, whether it’s a 1mm architectural panel or a 3mm thick LED frame.

In precision parts, 0.5 degrees can mean failure. CNC bends stay within ±0.1°, reducing inspection time and improving overall production speed.

Conclusion

CNC press brake machines automate metal bending with precision and efficiency. They offer unmatched repeatability, lower production costs, and support across many industries where quality matters.