Starting with a problem: many people begin CNC machining without clear idea how fast the cutting tool should spin. They run at wrong speed and ruin the workpiece, or waste time.

Spindle speed in CNC means how fast the cutting tool rotates per minute (RPM). It determines how the tool engages with the material.

Spindle speed matters a lot for cut quality, tool life, and machining time. This article explains how spindle speed works, why it matters, material rules, and where to set it. Keep reading to avoid common CNC mistakes.

How is CNC spindle speed controlled?

Spindle speed is not random. It is set carefully. That decides how fast the tool spins.

The CNC controller or machine operator sets spindle speed through the machine control panel or program. It sends signals to the spindle motor to rotate at the chosen RPM.

When a CNC job begins, the operator or the CAM program sets the spindle speed value. This value is usually in revolutions per minute (RPM). The CNC controller sends a command to the spindle drive motor. The drive adjusts voltage or frequency to reach and keep that RPM. Modern CNC machines often use variable-frequency drives (VFD) or servo motors. These let the operator choose many speed levels. Older machines may use fixed pulley/belt systems, where mechanical pulleys decide a small set of speeds.

Types of spindle speed control

- Variable-frequency drive / inverter control: The controller changes the electrical frequency to adjust motor speed. This gives fine control and flexible RPM settings.

- Servo motor control: The machine uses a servo motor that the controller can precisely set to any RPM within its range. It also keeps RPM stable under load.

- Mechanical pulley/belt drive: The machine has fixed pulley sizes; changing a belt or pulley changes speed in steps. This gives few discrete speed options.

In many shops, the spindle speed is specified in the CAM program or G‑code file. For example, a G‑code line might say S1200 to set 1200 RPM. When the CNC program reaches that line, the control sends command to spindle drive and waits until it reaches 1200 RPM before proceeding.

On some machines, the operator can override speed manually via control panel while machining. This helps adjust speed in real time if cutting feels too slow or causing chatter.

Because of these control methods, modern CNC machines offer good flexibility and allow precise tuning for different tools and materials. That helps improve cut quality and tool life.

Why does spindle speed affect machining?

Fast or slow tool spin changes how the cutting tool interacts with material. The wrong speed can damage tool or part.

Spindle speed affects cutting quality, heat generation, tool wear, and machining efficiency — too fast or too slow causes bad results.

When a tool rotates, its cutting edge meets material. The speed of rotation defines how many times per minute the edge passes a point on the material. If the speed is too high, the tool may cut too fast. This creates heat, melts or burns material (especially plastics or soft metals). High heat can warp the part or reduce tool life. It may also cause rough surface or chatter marks.

If the speed is too low, the tool may drag instead of cut cleanly. This leads to tearing, rough surfaces, or extra force on tool and machine. Low speed can also cause poor chip evacuation. Chips may clog the tool, scratch the surface, or break the tool.

Another key factor is the cutting tool itself. Tools have design limits (material, coating, flute geometry). Each tool works best in a speed range. Outside that range tool may dull fast or break.

Also material type matters. Softer materials often need lower speed. Hard materials need higher speed for clean cut, but too high can burn or overheat. So operator must match speed to both tool and material.

Lastly, spindle speed links to feed rate (how fast tool moves along material) and cutting depth. A balanced combination ensures smooth cut, good surface, and long tool life. Changing spindle speed without adjusting feed or depth can still cause problems.

Thus spindle speed is key to machining success. Proper speed improves cut quality, extends tool life, avoids part damage, and reduces wasted time.

Which materials require specific spindle speeds?

Different materials need different spindle speeds. Using a wrong speed can ruin work or even break tool.

Each material has a recommended RPM range based on hardness, thermal properties, and chip behavior. Some materials need slow speed, some fast, some medium.

Here is a simple table of common materials and typical spindle speed guidance:

| Material | Relative Hardness | Typical Spindle Speed Range (RPM) |

|---|---|---|

| Soft Wood (pine etc) | Very soft | 800–2000 |

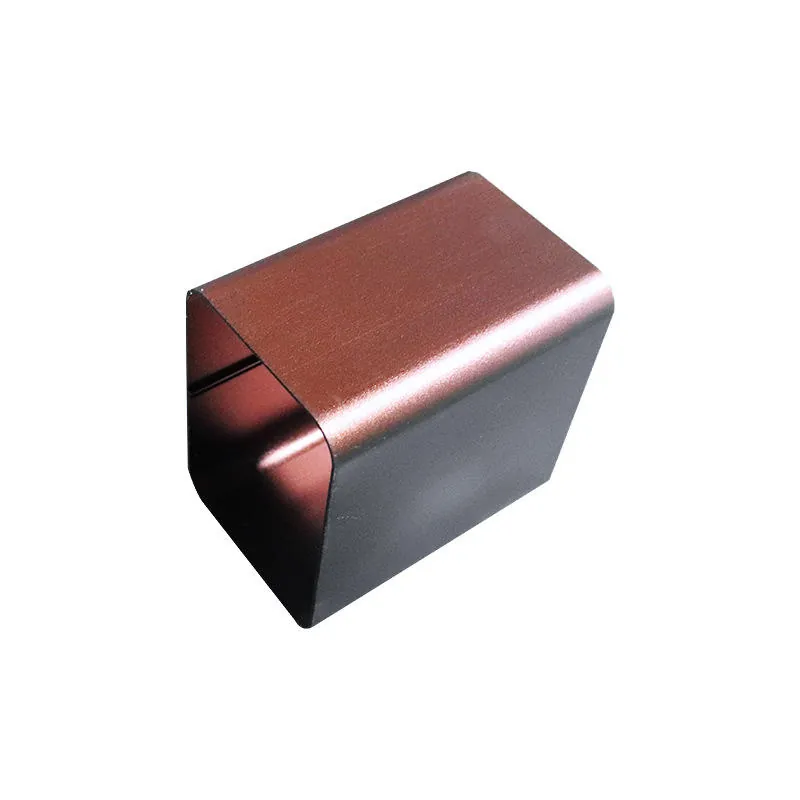

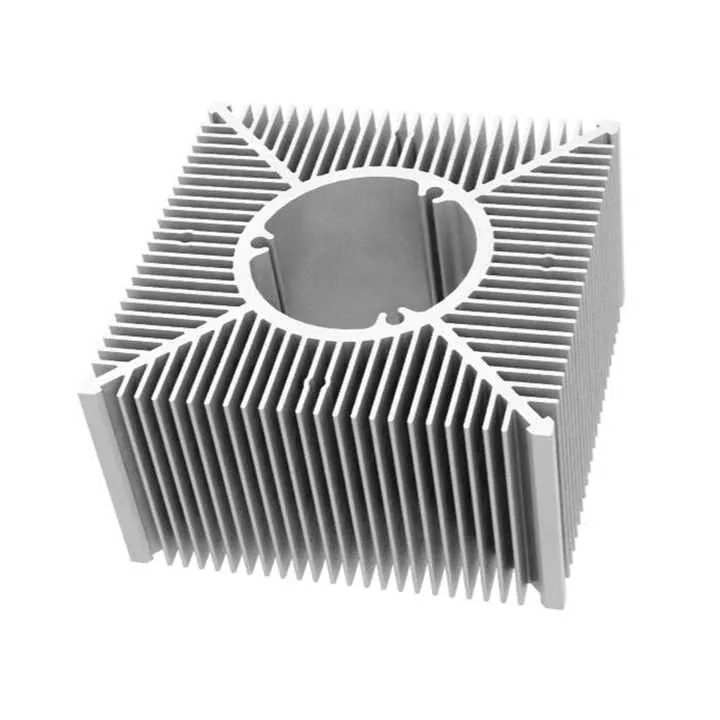

| Aluminum (6061, 6063) | Soft metal | 1000–3000 |

| Mild Steel | Medium hardness metal | 600–1500 |

| Stainless Steel | Hard metal | 400–1000 |

| Acrylic / Plastic | Soft but sensitive | 600–1500 |

| Brass / Copper | Soft metal | 800–2000 |

The table gives rough RPM ranges. Each case may change due to tool type, tool diameter, depth of cut, and coolant use.

Why material nature changes speed needs

Soft materials

Soft wood or plastic tend to melt or burn if spin is too fast. Their chips can smear or clump. To cut clean, spindle speed must stay moderate. Lower speed gives cleaner cut and reduces heat.

Metals

Metals offer resistance to cutting. Soft metals like aluminum cut clean at higher speeds because they shear easily. Hard metals like stainless steel cause heat and tool wear if speed is too high. Lower speed helps prolong tool life and avoid overheating.

Tool and chip factors

Tool size and shape matter. A small diameter tool spins faster than a large one. Deeper cuts or harder materials need slower speed. Coolant can help at higher speed by reducing heat.

In practice, I often check manufacturer recommendations for tool + material. Then I start at low end of range and watch chip shape, finish, and noise. If cut is smooth and chips clean, I can increase speed a bit. If chips melt, tool smokes, or finish is rough, I reduce speed.

Also combining speed with feed rate matters. For example, with aluminum, a 6 mm end mill at 2000 RPM and correct feed gives good finish. But if feed is too slow at that RPM, aluminum may melt. That leads to built‑up edge and poor finish. So I always treat speed and feed together when choosing settings.

Where do operators adjust spindle speed?

Spindle speed is set either in the CNC program or via machine controls. Operator chooses where based on job needs and machine type.

Operators adjust spindle speed in the machine’s control panel, in the CNC program (G‑code), or via CAM tool settings before running the job.

Often the process works like this: When programming the job in CAM software, the user picks tool, material, and cutting parameters. The CAM then writes a G‑code file. In that file lines like S1500 instruct the machine to spin at 1500 RPM. When the machine reads that line, the controller sends command to spindle drive.

In some jobs, the operator may want to adjust speed during machining. Common reasons: material is inconsistent, tool shows vibration, or finish is not good. On many CNC machines, the control panel has a spindle override knob or keypad. The operator can raise or lower speed in real time.

Here is a table summarizing typical adjustment sites:

| Setting Method | Where It Is Adjusted | When It Is Used |

|---|---|---|

| G‑code in CNC program | In code file before run | For fixed, repeatable jobs |

| CAM software tool path | In CAM before code generation | For planning jobs with tool/material data |

| Machine control panel | On machine during running | For fine‑tuning, response to problems |

If a project uses multiple materials or tools, each tool path can set its own spindle speed. That helps optimize for each cut. For example, drilling may use 1200 RPM, rough milling 1800 RPM, finishing 2500 RPM.

In some shops, speed setting is part of standard operating procedure. The operator fills in a setup sheet before work begins. That sheet includes tool type, material, spindle speed, feed rate, and depth of cut. This helps maintain consistency and prevent mistakes.

Sometimes the machine has presets or memory entries for common materials. Operator selects the material type and machine suggests default speed. That saves time and lowers error.

By choosing spindle speed carefully at setup or adjusting during run, operators control tool life, surface finish, cut quality, and cycle time. This control matters a lot for efficiency and quality in CNC machining.

Conclusion

Spindle speed in CNC is the rotation rate of the cutting tool. It controls how clean, fast, and safe the cut is. Different materials need different speeds. Operator sets speed in program or machine panel. Choosing correct speed helps quality, saves tool life, and avoids waste.