Starting out with metal joining feels risky and slow. Many worry about consistency and human error in welding jobs. CNC welding offers a precise, automated path to solve that worry.

CNC welding is a method that uses computer‑controlled machines to join metal parts automatically. The system guides welding tools along programmed paths, giving accurate, repeatable welds while reducing manual work.

If you want reliable weld quality and faster production, read on. Below is a breakdown of how CNC welding works, why it is popular in fabrication, what materials it suits best, and where industries apply it worldwide.

How does CNC welding automation work?

Starting welding by hand can feel risky and uneven. Mistakes happen easily if a worker slips. CNC welding automation removes that risk by having a machine follow exact instructions.

In CNC welding systems, a computer program controls the welding equipment to carry out welds automatically using precise coordinates. The program defines where, how, and when to weld, giving high repeatability and consistent quality.

CNC welding automation works in several stages. First, a welding engineer or technician creates a digital model of the parts to be welded. That model includes the exact geometry and where welds should occur. Next, a CNC welding program is generated. This program contains the welding path, speed, angle, weld length, and sequence. The program is loaded into the CNC welding machine’s controller.

The workflow in practice

-

Fixture and positioning

The metal parts are placed and secured in a fixture or jig. This keeps parts from shifting during welding. Without a stable fixture, welds could misalign. The fixture ensures consistent placement across many units. -

Program execution

The controller reads the program instructions. It moves the welding torch automatically along the specified path. The torch angle, travel speed, and welding parameters remain controlled. No manual hand‑welding is needed. -

Welding parameters control

The machine controls current, voltage, wire feed rate (if wire welding), shielding gas flow, and weld timing. These parameters stay constant, avoiding human variation. -

Monitoring and feedback

Many CNC welding machines include sensors or feedback systems. These systems watch weld pool temperature, speed, or torch position. If something goes wrong, the machine can stop. This protects quality and reduces defects.

Why automation improves quality

Because the machine always follows the exact same instructions, welds stay uniform for every part. Human welders may vary pressure, speed, or torch angle from part to part. CNC welding removes that variability. As a result, welds have consistent penetration, bead shape, and strength. That consistency matters most in large‑scale production where many identical parts must meet the same standards.

Also, automation cuts down on the fatigue and errors that come with repetitive work. Human welders may get tired, lose focus, or move slightly differently over time. Machines do not tire. They do not get distracted. This leads to less scrap, fewer re‑works, and better yield overall.

Finally, CNC welding often integrates well with other automated systems. For instance, CNC welding machines can fit inside production lines where CNC cutting or CNC bending also happens. This lets manufacturers streamline the entire metal fabrication process. The result is faster production and lower labor cost, while keeping high quality.

Why is CNC welding used in fabrication?

Manual welding gives flexibility but also brings lower speed and inconsistent quality. Many fabricators struggle with re‑work and variable output. CNC welding solves these issues by offering speed, precision, and repeatability.

Fabricators use CNC welding because it delivers high throughput, consistent weld quality, and reduced labor cost compared to manual welds. It helps meet tight tolerances and handles repetitive tasks well.

When shops face high volume orders or need repeatable precision, CNC welding becomes very attractive. It offers these advantages over manual welding:

Consistent Quality and Repeatability

Machines follow the same program every time. That means weld bead, depth, and penetration stay the same. This consistency lowers inspection failures. It ensures each part meets design specs.

Faster Production and Higher Throughput

CNC welding moves fast. It does not pause for rest or repositioning the same way a manual welder does. It also avoids downtime due to human fatigue. This speed helps meet tight deadlines and large orders.

Lower Labor Demand and Skill Dependency

Manual welding demands skilled welders. Skilled welders are scarce and pricey. CNC welding reduces reliance on manual labor. Less training is needed. Once programmed, machines work with minimal supervision. That frees human workers for tasks that need human judgment or finishing touches.

Better for Complex or Large Assemblies

For intricate structures with many welds, manual welding can be error-prone or slow. CNC welding handles complex paths, repetitive weld points, or long weld joints more easily. It also improves accuracy over long weld seams. That reduces waste due to misalignment or weak joints.

Cost Savings Over Long Run

Although CNC welding equipment is expensive upfront, over time it saves on labor and scrap. For large production runs, these savings add up. Fabricators get lower cost per part and more predictable production schedules.

Because of these reasons, CNC welding is common in industries like automotive, construction, structural metal work, frameworks, enclosure manufacturing, and heavy equipment fabrication. Anywhere you need many high-quality welds, CNC welding is a strong choice.

Which materials suit CNC welding best?

Some metals weld easily under automation. Others pose problems. Fabricators must match materials and welding methods carefully. Using the wrong material or thin gauge can lead to defects.

CNC welding works best with common weldable metals such as mild steel, stainless steel, aluminum alloys, and some heat‑treatable alloys. These materials offer good weldability and consistent behavior under automated controls.

Here is a summary table covering materials and how suitable they are for CNC welding:

| Material Type | Suitability for CNC Welding | Comments on Behavior |

|---|---|---|

| Mild Steel (low‑carbon) | High | Easy to weld, stable heat zone, forgiving |

| Stainless Steel | High | Good corrosion resistance, good for precision welds |

| Aluminum Alloys | Medium–High | Needs proper parameter control, clean surface needed |

| High‑Strength Alloys | Medium | Requires precise heat control to avoid warping |

| Copper/Brass | Low–Medium | Conducts heat fast, harder to control weld pool |

| Galvanized Steel | Low | Coating vaporization can cause defects and fumes |

Why some materials work better than others

-

Mild steel: This metal is very weldable. It melts and fuses easily under common welding methods like MIG or TIG. The heat zone stays stable. This makes it ideal for automated welding where the torch path stays fixed.

-

Stainless steel: It welds well when using proper shielding gas and parameters. Automation ensures consistency in speed and torch angle. That leads to clean welds with good strength and corrosion resistance.

-

Aluminum alloys: These metals need more care. Aluminum has high thermal conductivity. If welding heat or speed is wrong, the weld can burn through or distort the part. CNC welding manages these factors precisely, so aluminum can be welded reliably when settings are correct. Pre‑cleaning the surface helps avoid contamination and porosity.

-

High‑strength alloys: These alloys need careful control. Heat can change metal properties or cause warping. CNC machines regulate heat and speed carefully. Still, these alloys may need post‑weld heat treatment or inspection to confirm strength.

-

Copper, brass, zinc‑coated metals: These are harder. They conduct heat quickly or vaporize coatings. That makes weld control tricky. Unless a shop tunes parameters well and possibly preps the surface, weld results may be inconsistent. For many fabricators, these metals remain less ideal for CNC welding.

In practice, shops pick materials that weld cleanly and consistently under automation. They avoid metals that require complex procedures unless absolutely necessary. That choice helps ensure yield, quality, and repeatability.

Where is CNC welding widely adopted?

Many industries across the world need reliable, repeatable welding for parts and structures. CNC welding fits exactly those needs. That makes it popular in many areas — not just heavy industry.

CNC welding finds wide use in sectors such as automotive manufacturing, structural steel fabrication, solar panel framing, lighting fixtures, heavy machinery, and building construction. These fields need many welds with consistent quality and they value speed and cost efficiency.

Typical application areas

Here is a table listing sectors and common CNC welding uses:

| Industry / Sector | Common Use Cases | Why CNC Welding Helps |

|---|---|---|

| Automotive Manufacturing | Car frames, chassis parts, brackets | High volume, tight tolerances, repeatability |

| Structural Steel Fabrication | Beams, trusses, support frames | Long welds, strong joints, consistent quality |

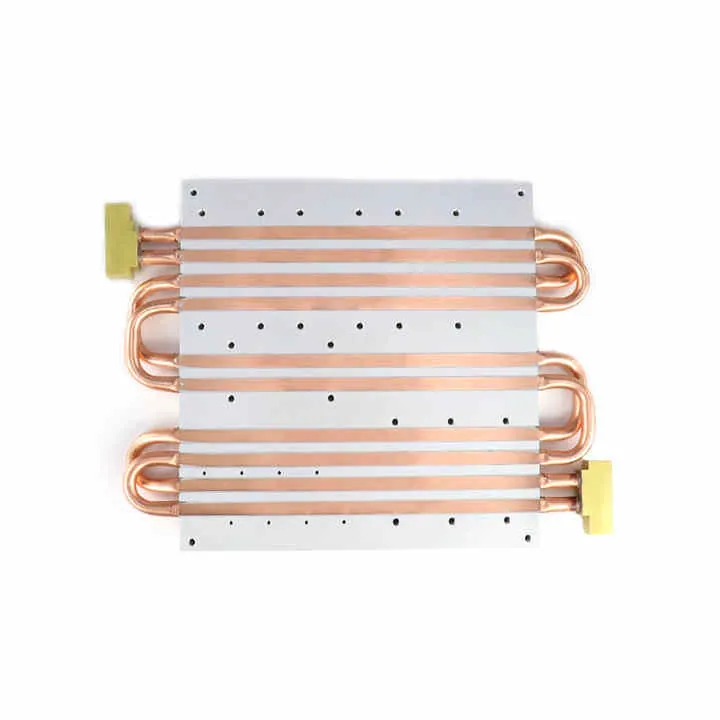

| Solar Panel Frames & Racking | Aluminum frames and supports | Lightweight alloys, precision needed |

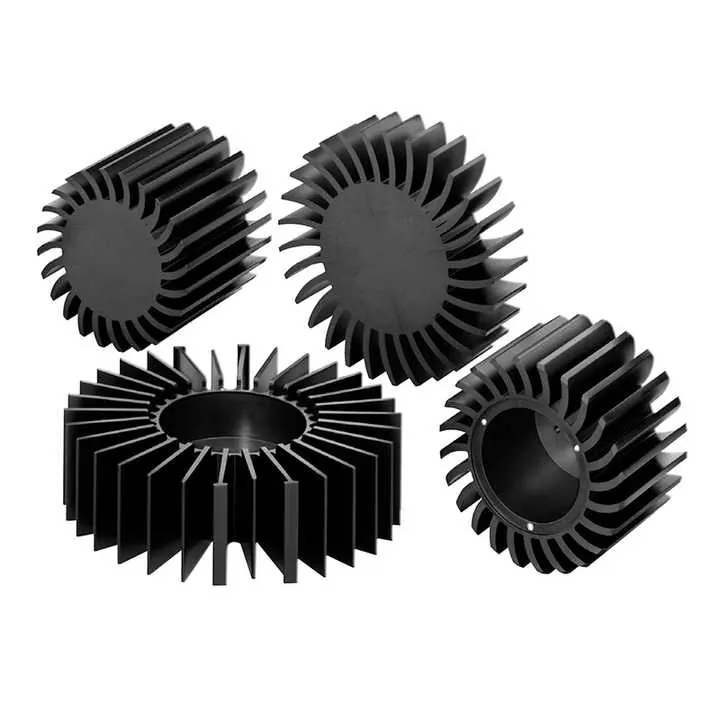

| Lighting Fixtures & Enclosures | Lamp bodies, housings | Sheet metal precision, clean weld seams |

| Heavy Machinery & Equipment | Frames, supports, housings | Thick metal, heavy structure, durability |

| Building Construction | Railings, staircases, metal frameworks | Uniform welds over many units, safety assurance |

Why these industries adopt CNC welding

-

Automotive industry often builds thousands of identical parts. CNC welding keeps every part the same. It reduces rejection rate. It speeds up throughput. It also helps meet safety and strength standards.

-

Structural steel shops build frames and supports that carry heavy loads. They need straight weld seams and uniform strength. CNC welding ensures welds are even, correctly placed, and strong. Weld consistency matters for structural integrity.

-

Solar panel frame manufacturing often uses aluminum. CNC welding controls heat and speed so aluminum frames stay precise and light. The frames must align exactly for panel mounting. Automation ensures that precision.

-

Lighting and enclosure fabrication demands clean weld seams and neat finish. CNC welding delivers smooth joints and consistent weld quality. That reduces finishing time (grinding, smoothing). It makes final products cleaner and ready for finishing or painting quickly.

-

Heavy machinery manufacturing requires thick metal welds and strong joints. CNC welding delivers consistent heat delivery and torch control. That helps weld thick plates without defects. For bulky or large frames, automation ensures uniformity across many segments.

Global and regional demand

CNC welding is common in factories around the world — from North America, Europe, to Asia and Africa. Wherever manufacturing and fabrication happen at scale, CNC welding has found a place. As more industries move toward automation, the demand rises.

In regions where labor is costly or skilled welders are scarce, CNC welding brings strong value. It cuts dependence on skilled manual welders. That helps in places with labor shortage. It also helps keep costs predictable.

In sectors where quality standards and safety regulations are strict — for instance, automotive safety, building codes, or structural load requirements — CNC welding offers consistent compliance. That makes it the go‑to method in many certified manufacturing operations.

Conclusion

CNC welding lets factories join metals with high precision, speed, and repeatability while cutting labor dependence. It suits common metals like steel, stainless steel, and certain aluminum alloys. Industries that need many consistent, strong welds — from automotive to structural steel, solar frames to heavy equipment — rely on CNC welding worldwide. As automation grows, CNC welding will stay a key tool in modern fabrication.