Modern manufacturing looks completely different from the past. Manual labor and simple tools are no longer enough to meet today’s speed and precision demands. That's where CNC machine tools come in.

A CNC machine tool is a computer-controlled device that shapes, cuts, drills, or mills material with extreme precision. It automates machining by following pre-set digital instructions.

These tools are transforming industries. They're not only faster than manual methods but also more accurate and cost-efficient. Let’s explore how they work and why they matter.

How do CNC machine tools function?

Manual machining is slow and error-prone. Operators must measure, adjust, and cut every time by hand. That creates room for mistakes and inconsistent quality.

CNC machine tools work by reading coded instructions called G-code, which tell the machine what actions to take, how fast to move, and where to go.

They use computers to control movement across multiple axes — typically X, Y, and Z. A spindle rotates cutting tools, and servo motors ensure accurate positioning. These machines handle different materials, from metals and plastics to composites.

How CNC tools operate step by step:

- CAD design – First, a digital drawing is created using CAD (Computer-Aided Design) software.

- CAM programming – Then, CAM (Computer-Aided Manufacturing) software converts the design into G-code.

- Machine setup – The operator loads material into the machine.

- Execution – The CNC machine reads the G-code and follows each command precisely.

Key components of a CNC machine:

| Component | Function |

|---|---|

| Controller | Brain of the machine, processes G-code |

| Servo motors | Move components precisely |

| Spindle | Rotates the cutting tool |

| Tool turret | Holds and changes tools |

| Worktable | Supports the raw material |

Because they run on software, CNC machines can repeat tasks perfectly. That consistency is hard to achieve with manual methods.

Why are CNC machine tools essential?

Manufacturing without CNC tools is like writing books by hand in the digital age. It's slow, costly, and inconsistent.

CNC machine tools are essential because they offer high precision, fast production, repeatability, and cost-efficiency across various industries.

They allow businesses to scale operations while keeping quality high. Even small batches can be produced with exact specifications. This is especially important in industries like aerospace and automotive, where precision matters.

Benefits of using CNC tools:

| Benefit | Explanation |

|---|---|

| Precision | Achieves tolerances within microns |

| Speed | Reduces time compared to manual machining |

| Automation | Runs unattended for long hours |

| Safety | Keeps workers away from dangerous manual operations |

| Flexibility | Can switch between tasks by changing the program |

| Consistency | Produces identical parts every time |

A CNC system can also work around the clock, including overnight or during weekends, without fatigue. That leads to increased productivity and reduced labor costs.

These tools also reduce waste. Fewer errors mean fewer raw materials are lost. Over time, this adds up to major savings and better sustainability.

Which tasks require CNC machine tools?

Some tasks demand more than just precision — they require repetition, complexity, or delicate materials. Manual tools can’t keep up with such demands.

CNC machine tools are used for cutting, drilling, milling, turning, engraving, and shaping parts in manufacturing and prototyping.

Different types of CNC machines are suited to different jobs. For example, a CNC lathe spins material and uses cutting tools to shape it, while a CNC milling machine rotates tools to remove material from the surface.

Common tasks performed by CNC machines:

- Cutting sheet metal to size with laser precision

- Drilling holes in exact locations for assemblies

- Engraving serial numbers on parts

- Milling complex surfaces like engine components

- Turning cylindrical objects for plumbing or machinery

CNC machine types and their functions:

| Machine Type | Task Description |

|---|---|

| CNC Milling | Cuts and shapes material using rotating tools |

| CNC Lathe | Spins material and cuts with stationary tools |

| CNC Router | Handles soft materials like wood or plastic |

| CNC Plasma Cutter | Cuts metal using a plasma torch |

| CNC Laser Cutter | Uses laser beams for fine, detailed cutting |

Each machine offers unique capabilities. Together, they form a complete toolkit for modern factories.

Where are CNC machine tools used?

Not all industries need CNC tools, but those that do depend on them completely. Their accuracy and automation are key to staying competitive.

CNC machine tools are used in aerospace, automotive, electronics, medical, construction, and energy industries for precision manufacturing.

These industries require parts that meet strict standards. In some cases, like in medical implants or airplane parts, failure is not an option. CNC machining ensures each part meets exact specs.

Industries and applications:

| Industry | Application Examples |

|---|---|

| Aerospace | Engine parts, wing components, structural supports |

| Automotive | Gear systems, pistons, brake systems |

| Medical | Surgical tools, bone plates, dental implants |

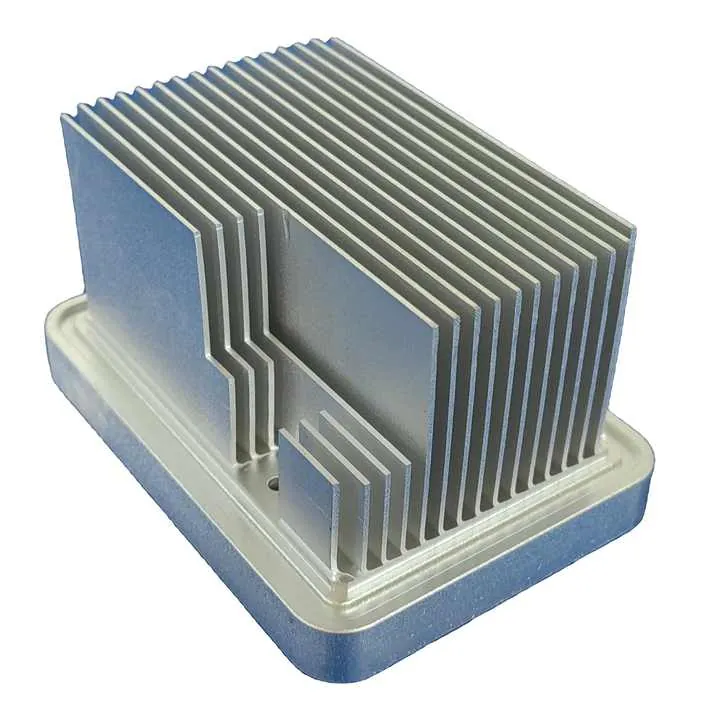

| Electronics | Phone casings, PCB enclosures, heatsinks |

| Construction | Metal frames, support beams, brackets |

| Renewable Energy | Wind turbine hubs, solar panel frames |

Why these industries need CNC:

- Precision – Even tiny errors can cause failures in airplanes or medical tools.

- Durability – CNC-made parts meet high mechanical standards.

- Efficiency – Fast production keeps costs low and deadlines on track.

In construction, CNC helps build aluminum framing systems used in windows, doors, or curtain walls. In electronics, CNC makes cases and connectors used in millions of devices. Even in art and design, CNC can create sculptures and prototypes with great detail.

Conclusion

CNC machine tools are the backbone of modern manufacturing. They automate complex tasks with speed and precision. From cutting metal to shaping medical tools, they deliver the reliability industries need to grow and innovate.