A small misalignment can ruin an entire production run. Traditional drilling methods often fail under tight tolerance requirements. CNC drilling solves this with automation and accuracy.

A CNC drilling machine is a computer-controlled system designed to automate the process of drilling holes with extreme precision, repeatability, and speed in a variety of materials.

Unlike manual drilling, CNC machines follow digital commands with no room for human error. Let’s look deeper into how they work, why they’re trusted, and where they’re most used.

How does a CNC drilling machine operate?

Many workshops still rely on manual machines, which require constant supervision. This limits consistency and throughput. CNC drilling replaces this with full automation and computer programming.

A CNC drilling machine operates by following programmed instructions (G-code) to drill holes in specific positions, using servo motors and sensors to ensure accuracy.

CNC drilling starts with a design, usually created in CAD software. That file is converted into G-code, which gives the machine step-by-step instructions. The workpiece is clamped onto the table, and the spindle, controlled by motors, moves along pre-defined axes to drill at exact points.

Key Components of a CNC Drilling Machine

| Component | Function |

|---|---|

| Spindle | Rotates the drill bit |

| Servo Motors | Control the movement of the axes |

| Control Panel | Interface for loading programs |

| Tool Changer | Switches drill bits automatically |

| Worktable | Holds the material in place |

The movement is guided by the X, Y, and Z axes. The Z-axis handles vertical movement—up and down of the drill bit—while X and Y handle horizontal positioning. Some machines even include a fourth (A) or fifth (B) axis for more complex angles.

CNC Drilling Workflow

- CAD model is created.

- CAM software generates G-code.

- G-code is sent to the CNC machine.

- Material is loaded and clamped.

- Drilling starts and completes automatically.

This reduces waste, human errors, and variability, especially in mass production. In industries where parts must match within microns, CNC drilling is the go-to.

Why use CNC drilling for precision?

Manual drilling often depends on the operator’s skills. Small shifts in angle or depth can lead to bad fittings. In high-stakes industries, that’s too risky.

CNC drilling offers unmatched precision due to its automated movements, computer control, and advanced feedback systems that adjust in real time.

The biggest reason for CNC precision is its repeatability. Once the machine is programmed, it will drill the same hole in the same spot, every single time, down to a fraction of a millimeter.

What Makes CNC Drilling Accurate?

| Feature | Impact on Precision |

|---|---|

| Closed-loop feedback | Detects and corrects positioning |

| Tool calibration | Ensures bit is aligned perfectly |

| High-quality spindles | Reduce vibration and deviation |

| Rigid machine structure | Prevents flexing during operation |

Use Cases Requiring High Precision

- Aerospace components like brackets or casings

- Medical devices with tiny holes

- Automotive engine blocks

- Circuit boards requiring micro drilling

These parts often require tolerances within ±0.01 mm. Manual tools simply can’t deliver this consistency. Also, high-speed drilling under CNC control doesn’t sacrifice quality. In fact, it often improves surface finish, edge sharpness, and hole roundness.

Which tasks require CNC drilling?

Many people think CNC drilling is only for metal parts. But it’s used far beyond that. From wood to plastic to carbon fiber, the process is adaptable.

CNC drilling is required for tasks that involve repetitive, complex, or high-precision hole-making in a variety of materials and shapes.

Common Drilling Tasks in Different Industries

1. Metal Fabrication

Factories producing metal parts for construction or machines often use CNC drilling to create mounting holes, bolt paths, or threaded inserts. The hardness of metal demands precise bit control, which CNC handles easily.

2. PCB Manufacturing

Printed circuit boards require extremely small, clean holes. Manual drilling would destroy these delicate components. CNC micro-drilling machines are designed for such tasks.

3. Furniture Production

High-end wooden furniture often includes concealed fasteners. CNC drilling enables perfect placement, even on curved surfaces. It also speeds up production without losing quality.

4. Plastic Component Assembly

Consumer electronics and home appliances use plastic shells that must be assembled with screws or rivets. CNC machines drill the holes with high repeatability to ensure proper alignment.

Types of CNC Drilling Operations

| Operation | Description |

|---|---|

| Peck Drilling | Bit withdraws to remove chips |

| Deep Hole Drilling | Used for thick materials |

| Spot Drilling | Prepares surface before full drilling |

| Counterboring | Makes space for bolt heads |

Each of these tasks has one thing in common: need for consistency. Whether it’s 10 holes or 10,000, CNC machines drill them all exactly the same.

Where is CNC drilling applied?

Drilling machines are not just used in factories. They're also used in fields as diverse as aviation and energy. The reach of CNC drilling spans multiple industries.

CNC drilling is applied in aerospace, automotive, electronics, construction, medical, and even renewable energy industries due to its versatility and efficiency.

CNC Drilling Applications by Industry

Aerospace

Aircraft frames, turbine parts, and fuselage panels all rely on tight tolerances. CNC drilling ensures every hole matches exact specs to prevent air leakage or stress cracks.

Automotive

From engine blocks to brake components, cars have thousands of drilled holes. Most are safety-critical. CNC helps automate this without losing quality.

Electronics

In PCB assembly, components are inserted into drilled holes before soldering. The margin for error is extremely small. Only CNC machines can deliver the needed scale and accuracy.

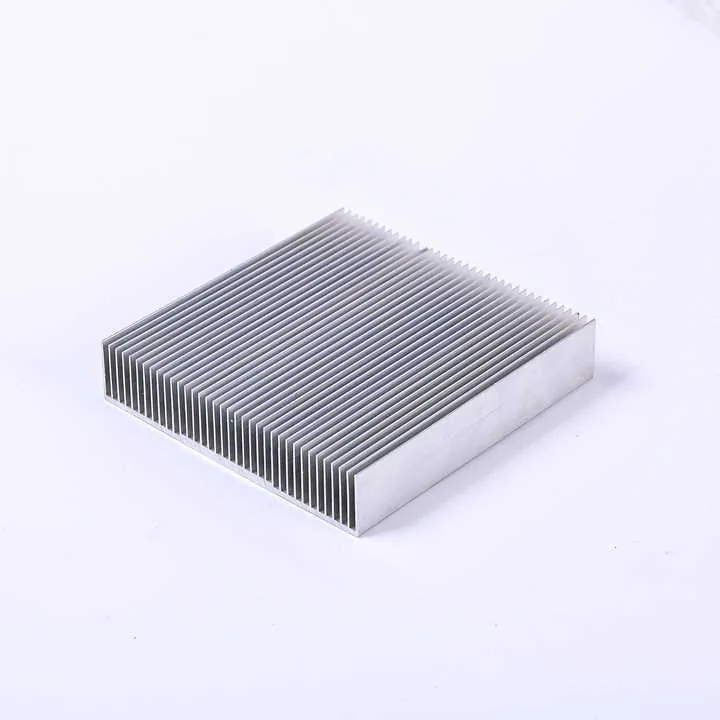

Construction

Aluminum frames, steel reinforcements, and curtain walls need holes for bolts, fasteners, or electrical access. CNC drilling on construction-grade materials saves labor costs and time.

Medical

Surgical tools, implants, and diagnostic devices often require micro holes. Here, cleanliness and dimension accuracy are vital. CNC ensures contamination-free, clean holes with minimal burring.

Renewable Energy

Solar panel frames, wind turbine parts, and energy storage units also require precision drilling. CNC machines work with metals like aluminum or composites without damaging them.

Benefits Across Industries

| Benefit | Outcome |

|---|---|

| Faster production | Meets tight deadlines |

| Lower error rates | Reduces rework and waste |

| High consistency | Improves product quality |

| Adaptability | Works on different materials |

Because of these benefits, many companies are now shifting from manual to CNC drilling. It’s a key part of automation in modern manufacturing.

Conclusion

CNC drilling machines change the way holes are made—faster, cleaner, and with far more control. From aerospace to furniture, they're now essential in modern manufacturing for reliable, precision results.