Many people hear the term “CNC machining centre” and wonder what it actually means. Why is it so widely used in manufacturing today?

A CNC machining centre is a high-precision, computer-controlled machine used to cut, drill, mill, or shape materials like metal and plastic into exact parts.

This article will help you understand how CNC machining centres work, why they matter, what jobs they handle best, and where they are used in the real world.

How does a CNC machining center function?

CNC machining sounds complex—but it’s actually a logical and repeatable process.

A CNC machining center works by following digital instructions to move tools and materials in exact directions and perform precise operations automatically.

These machines use software programs to control motors, spindles, and axes. You start with a digital drawing (CAD file). That file becomes a coded program (usually G-code). The program tells the machine where to cut, how deep to go, and how fast to move.

Main Components of a CNC Machining Centre

| Component | Function |

|---|---|

| Controller | Reads G-code and tells the machine what to do |

| Spindle | Rotates the cutting tool at high speeds |

| Tool Changer | Switches tools automatically during a job |

| Worktable | Holds the material in place during machining |

| Axes (X, Y, Z) | Move the tool or material for cutting in multiple directions |

Some machines have more than three axes. With 4 or 5 axes, the tool can approach the material from different angles. This helps when making curved or complex parts.

The entire process is automated. Once the design is approved, the operator loads the material, starts the program, and the machine does the rest. Many operations, like drilling, milling, tapping, and contouring, can be done in one setup without human interference.

That’s how CNC centres maintain quality and reduce errors.

Why are machining centers essential for precision?

In industries where even a 0.1 mm error is too much, only machining centres can meet the demand.

Machining centers are essential because they offer exact, repeatable results with minimal error across multiple parts.

Manual machines can’t hold the same tolerances. Operators get tired. Setups shift. But with CNC, everything is controlled by code. Every part is cut the same way, with the same speed and depth.

The machines also avoid common causes of errors like tool chatter, uneven pressure, or heat build-up. The rigidity of the machine and the control software work together to deliver clean, accurate cuts.

CNC centres also help improve surface finish. Parts look smoother, fit better, and last longer. This is important in industries like:

- Aerospace (where parts must survive vibration and heat)

- Automotive (where moving parts must fit and function)

- Electronics (where tiny parts must match exact specs)

Whether you’re making 10 parts or 10,000, machining centres ensure consistency.

Which tasks require CNC machining centers?

Not every project needs a machining centre. But many tasks become faster and better when you use one.

CNC machining centers are ideal for complex designs, repeat production, high-precision jobs, and multi-step tasks that need automation.

Here are typical tasks where CNC centres are used:

Typical Tasks

- Milling: Cutting flat or shaped surfaces

- Drilling: Making holes with exact spacing and depth

- Tapping: Cutting internal threads in holes

- Engraving: Adding letters, codes, or symbols

- Surface finishing: Creating smooth, even textures

- Prototyping: Building a single model before mass production

- Batch production: Making 50, 100, or 500 identical parts

Manual machines can only do one of these tasks at a time. But a CNC machine can perform several in one run. That saves time and reduces mistakes.

Here’s a quick comparison:

| Task | Manual Machine | CNC Machining Centre |

|---|---|---|

| Accuracy | Depends on skill | Guaranteed by code |

| Speed | Slow, one step at a time | Fast, automated |

| Repeatability | Hard to match parts | Identical every time |

| Complex shapes | Very difficult | Easy with 4/5 axes |

| Tool changes | Manual | Automatic |

That’s why industries like medical tools, automotive parts, aerospace parts, and electronics use CNC daily. Even in furniture and lighting, CNC helps create clean joints and perfect finishes.

Where are CNC machining centers used?

CNC machining centres are used worldwide in almost every modern industry.

Industries like aerospace, automotive, medical, energy, and consumer electronics all depend on CNC machining centres to make critical components.

Let’s look at where these machines are making a difference:

Key Industries

- Aerospace: Making lightweight, high-strength parts like brackets and housings

- Automotive: Producing gears, engine blocks, brake components

- Medical: Crafting surgical tools, implants, and diagnostic devices

- Solar & Energy: Building frames, brackets, and supports

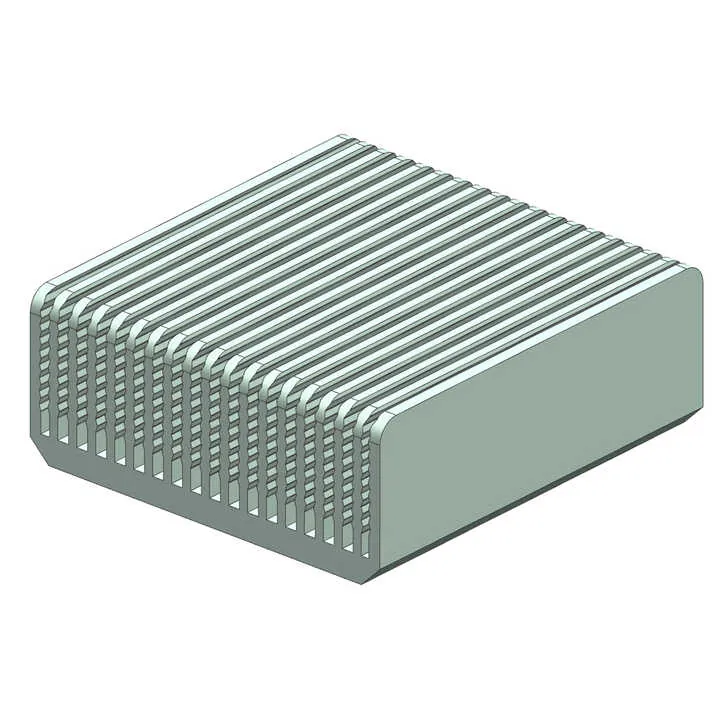

- Electronics: Shaping heat sinks, casings, and mounting parts

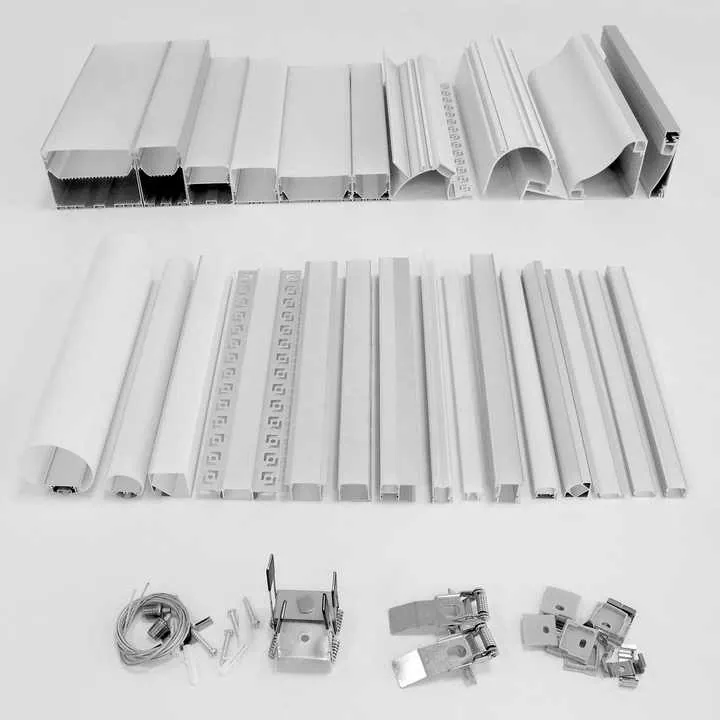

- Construction: Making aluminum profiles, joints, and framing systems

- Tooling: Cutting dies and molds used in other manufacturing

Factories use CNC for both prototyping and mass production. Here’s how:

| Use Case | Description |

|---|---|

| Prototyping | Quickly make and test a new part before full production |

| Custom Orders | Make small batches of custom parts for different clients |

| Mass Production | Run thousands of parts with exact same quality |

| Replacement Parts | Recreate or repair old machine parts with precision |

CNC centres also help small workshops compete. They can offer high-quality parts without large labor costs. In global trade, buyers often expect CNC‑grade precision. So even small suppliers invest in these machines to win deals.

Because CNC works with aluminum, steel, brass, plastic, and composites, it fits nearly any production line.

Conclusion

CNC machining centres are the backbone of precision manufacturing. They turn designs into reality with accuracy, speed, and flexibility. From tiny screws to structural frames, they shape the world we live in—quietly, perfectly, and reliably.