Today, manufacturers face high demand for precision, speed, and customization. Traditional methods often fail to meet these needs. CNC machining offers a smarter solution.

CNC machining is a manufacturing process that uses computer-controlled machines to cut, shape, and produce high-precision parts from metal or plastic materials.

Unlike manual production, CNC systems follow exact instructions programmed into a computer. This allows for complex and repeatable tasks at high speeds, improving quality and reducing human error.

How does CNC machining technology improve production?

When production goals are missed, it often comes down to human error or inconsistent quality. Many factories struggle with delays and rework. CNC machining solves this with automation and accuracy.

CNC technology improves production by delivering consistent quality, reducing manual labor, and speeding up the entire manufacturing process.

Consistent Results

Manual machining depends on the operator’s skill. Even small mistakes can result in costly waste or unsafe products. With CNC, each cut follows a programmed path. This ensures the same result every time.

Less Downtime

CNC machines can run 24/7 with minimal supervision. They don’t get tired or distracted. Downtime is reduced to scheduled maintenance or material changeovers. This boosts overall output.

Faster Production

Once the machine is programmed, parts can be produced quickly without further setup. Complex geometries, which might take hours manually, are completed in minutes. This is especially helpful in large-scale production runs.

Better Use of Labor

Instead of spending hours on repetitive tasks, skilled workers can shift to supervising operations, quality checks, or design improvements. This leads to a more efficient and motivated workforce.

| Production Feature | Manual Machining | CNC Machining |

|---|---|---|

| Accuracy | Varies by operator | High and consistent |

| Speed | Slower | Much faster |

| Labor Requirement | High | Low |

| Customization | Limited | Easily programmable |

| Reproducibility | Difficult | Simple and precise |

Why is CNC machining more efficient than manual methods?

Manual machining is time-consuming. Even simple cuts can take hours. Each part requires constant attention. CNC machining offers a better way—quick, repeatable, and hands-free.

CNC machining is more efficient than manual methods because it reduces errors, saves time, and allows for high-volume production with minimal waste.

Programmed Precision

In manual machining, every move depends on the operator’s hands. In CNC machining, each movement is guided by digital instructions. This removes guesswork and speeds up the process.

Less Material Waste

Mistakes in manual machining can ruin expensive materials. CNC machines follow exact dimensions. Errors are rare. This leads to better use of raw materials and lowers costs.

Fast Prototyping

In product development, time is critical. CNC allows engineers to test ideas quickly. By uploading a new design file, a prototype can be produced within hours, not days.

Complex Cuts Made Easy

Curved shapes, angles, or internal threads are hard to do manually. With CNC, these features are just another line of code. This opens up more design possibilities without slowing down production.

| Efficiency Area | Manual Methods | CNC Machining |

|---|---|---|

| Setup Time | Long | Short |

| Error Rate | High | Very Low |

| Material Waste | Frequent | Minimal |

| Prototype Speed | Slow | Fast |

| Production Scalability | Limited | Highly Scalable |

Which industries rely on CNC machining technology?

Without CNC machining, many modern products wouldn't exist. Cars, planes, electronics, and even medical devices all depend on this precise method of manufacturing.

Industries like aerospace, automotive, medical, and electronics rely heavily on CNC machining for producing accurate, complex, and reliable parts.

Aerospace and Aviation

In aviation, every part must meet exact standards. A small error could risk lives. CNC machines are used to make engine parts, brackets, and structural frames. These machines can work with tough materials like titanium and deliver tight tolerances.

Automotive Industry

Cars have hundreds of CNC-machined components—gears, pistons, engine blocks. Automation makes it possible to produce these parts in large volumes while maintaining quality.

Medical Equipment

Surgical tools, implants, and diagnostic machines all require small, complex parts. CNC machining allows for biocompatible materials and detailed shapes that manual methods can’t achieve.

Electronics

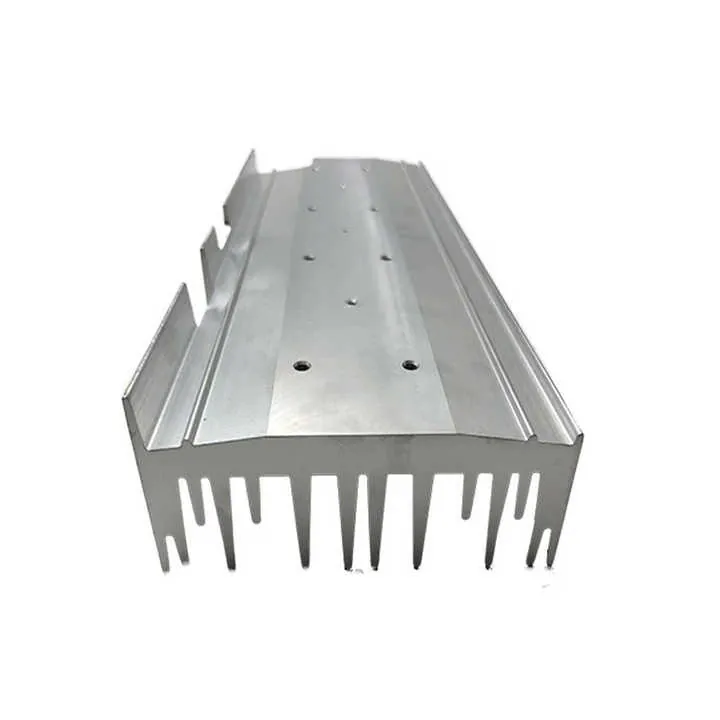

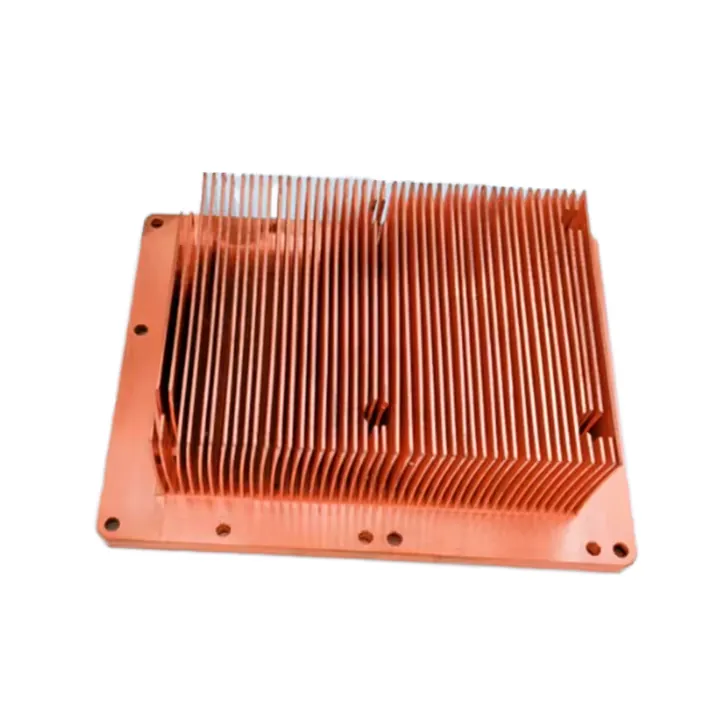

Devices like laptops and smartphones have aluminum frames and housings. CNC machining shapes these casings with high precision. It also helps produce heat sinks and connectors.

Industrial Machinery

Heavy machines need durable parts like shafts, housings, and fixtures. CNC machines can produce these to exact size, which is critical for performance and safety.

Custom Manufacturing

Smaller companies often use CNC for custom parts. This includes robotics, research tools, and one-off prototypes. The flexibility of CNC makes it ideal for low-volume but high-complexity jobs.

Where is CNC machining technology used?

You might think CNC machining is only for large factories. But its reach is much wider. From local workshops to global corporations, CNC machines play a role almost everywhere.

CNC machining is used in factories, research labs, hospitals, construction sites, and even space agencies for precise part fabrication.

Large-Scale Manufacturing

Major factories use CNC to maintain high output and consistent quality. These include automotive plants, aircraft factories, and electronics assembly lines.

Tool and Die Shops

These shops make molds and dies for other industries. CNC machines allow them to create precise shapes that are used in mass production.

Medical Labs and Hospitals

Custom implants and surgical tools are made using CNC machines. Hospitals also use CNC to repair or create lab equipment components quickly.

Universities and Research Centers

CNC is vital in testing and building experimental parts. Researchers use it to develop prototypes and validate mechanical designs.

Construction and Architecture

CNC can cut metal beams, decorative panels, and structural joints used in modern architecture. It helps in making both functional and aesthetic elements.

Space and Defense

NASA and defense companies use CNC to create parts for rockets, satellites, and defense systems. These parts must meet strict standards and function in extreme environments.

Conclusion

CNC machining technology transforms manufacturing with speed, precision, and flexibility. It supports industries from aerospace to healthcare, allowing them to meet modern production demands with confidence.