Many engineers ask this: is a laser cutter actually a CNC machine? This question often comes up when comparing different digital manufacturing tools.

Yes, a laser cutter is a type of CNC machine. It uses computer numerical control (CNC) to guide a laser beam for cutting or engraving materials.

Understanding the connection between laser cutting and CNC machining helps teams choose the right tool for precision, speed, and production efficiency. Let’s explore this more deeply below.

How does a CNC laser cutter differ from other CNC machines?

Some people assume all CNC machines work the same way. This leads to confusion when comparing milling, routing, and laser cutting systems.

CNC laser cutters differ from other CNC machines mainly by their tool: a high-powered laser beam instead of physical cutting bits.

A CNC machine is any tool controlled by a computer. This includes lathes, mills, routers, and laser cutters. While they all follow coded instructions, their functions and methods vary a lot. Here's how CNC laser cutters stand out:

Core Differences Between CNC Machines

| Feature | CNC Laser Cutter | CNC Mill | CNC Router |

|---|---|---|---|

| Cutting Tool | Focused laser beam | Rotary cutting tool | Spinning router bit |

| Contact with Material | No (non-contact) | Yes | Yes |

| Speed | Very high | Medium | High |

| Material Removal | Burns or melts | Chips away | Carves or cuts |

| Best For | Precision cuts, thin materials | 3D shapes, hard metals | Wood, plastics |

Laser cutters don’t touch the workpiece. They use heat to vaporize or melt the material. This means less wear on tools, fewer maintenance needs, and often higher precision.

In contrast, mills and routers use mechanical force. This allows them to shape 3D parts but often results in more stress on the material and tool.

Accuracy and Maintenance

Laser cutters also offer tight tolerances and clean edges. There's no tool deflection or wear affecting the output. This makes them ideal for tasks that demand fine details.

Because there's no contact, laser systems need less frequent calibration. They also generate less mechanical noise, vibration, and dust compared to traditional CNC machines.

Why is laser cutting considered a form of CNC machining?

People often separate laser cutting from CNC machining because the tool looks different. But the process behind it tells a different story.

Laser cutting is considered CNC machining because it uses computer-controlled motion to guide the cutting tool—just like any other CNC process.

Understanding CNC Principles

CNC stands for "Computer Numerical Control". Any process that uses a computer to move a tool in programmed paths falls under this term.

Laser cutters move the laser head using stepper motors, servo systems, and guide rails. G-code or other programming languages control the motion.

These programmed moves define paths, speeds, power levels, and more. So even if there's no traditional "cutting", the process follows the same automation logic.

Control System Breakdown

| System Part | Function in Laser Cutting |

|---|---|

| Motion Controller | Converts digital files into motion |

| Stepper Motors | Move the laser head across X/Y/Z axes |

| Power Supply | Delivers energy to the laser source |

| Optics System | Focuses and directs the beam |

| Software | Generates paths from CAD/CAM files |

Just like CNC milling or turning, laser cutting depends on exact machine feedback and positioning. This ensures every cut follows the design file precisely.

Also, many hybrid machines now combine laser cutting with other CNC functions like engraving or marking. This overlap makes the line between them even thinner.

Which tasks require laser cutting?

Laser cutting seems fancy or niche to some, but it’s actually used in many everyday industrial and design jobs.

Laser cutting is ideal for tasks that need precise, clean cuts in sheet materials such as metal, plastic, wood, and composites.

Laser systems handle jobs that are hard for physical tools. This includes thin metals, complex internal shapes, or delicate edges. Here’s a look at what tasks rely heavily on laser cutting:

Key Tasks Where Laser Cutting Shines

-

Precision Sheet Metal Cutting

Laser cutters slice steel, aluminum, brass, and copper sheets into exact shapes, often with zero finishing needed. -

Custom Enclosures and Panels

Electronics makers use laser cutting to create housings with accurate holes for connectors, screens, and ports. -

Signage and Lettering

Acrylic signs, metal letters, and wooden panels are cut with laser beams for smooth edges and sharp corners. -

Jewelry and Art Design

Designers cut intricate shapes in metal or wood for patterns too detailed for CNC routers. -

Medical and Aerospace Components

Thin-wall titanium parts or microcomponents benefit from low-heat distortion and perfect tolerances.

Comparing Cutting Tools

| Task Type | Laser Cutting | CNC Routing | Waterjet |

|---|---|---|---|

| Fine Detail | Excellent | Moderate | Good |

| Hard Metals | Limited (depends on laser) | Limited | Excellent |

| Plastics | Excellent | Good | Excellent |

| Cost Efficiency | High for thin materials | Medium | Low |

| Maintenance | Low | Medium | High |

Laser cutting is not perfect for thick or reflective materials unless using special systems. But for sheet-level precision and speed, it’s unmatched.

Where are CNC laser cutters used?

Some think laser cutters only belong in labs or art studios. But their industrial impact is massive.

CNC laser cutters are widely used in industries such as aerospace, automotive, electronics, signage, architecture, and medical device manufacturing.

These machines support mass production, rapid prototyping, and precision fabrication. Their ability to handle many materials and change jobs quickly makes them essential in today’s factories.

Major Application Fields

Aerospace

Laser cutters make lightweight aluminum panels, insulation layers, and complex metal components. They support quick turnarounds without tooling delays.

Automotive

Used to cut parts for interiors, brackets, and body components. The precision ensures proper fit in high-speed production lines.

Electronics

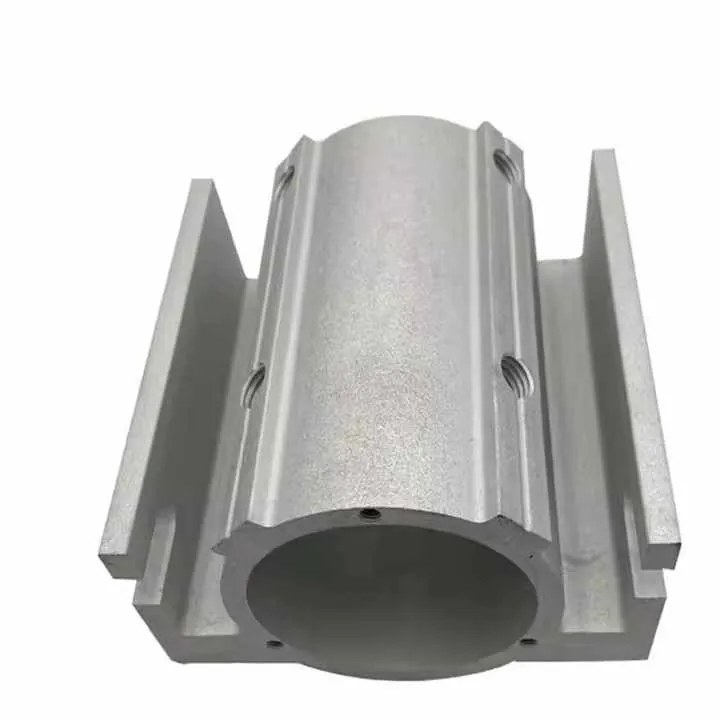

Cutting plastics and metals for circuit boards, enclosures, or heat sinks. Lasers avoid tool contamination or static risks.

Architecture and Signage

Cut decorative panels, gates, building details, and custom metal art. Designers rely on fine patterns and edge quality.

Medical Devices

Lasers cut stainless steel tubes, implant shapes, and sensor enclosures without affecting nearby materials.

Industry Use Cases Table

| Industry | Common Laser Cut Items |

|---|---|

| Aerospace | Sheet metal skins, brackets |

| Automotive | Interior panels, mounts |

| Electronics | PCBs, connector frames |

| Architecture | Panels, decorative frames |

| Medical | Implants, surgical parts |

Laser cutters are often part of flexible manufacturing cells. Operators upload a CAD file and start cutting within minutes. This agility helps meet tight deadlines and diverse product needs.

Conclusion

Laser cutters are indeed CNC machines. They follow digital commands to shape materials with precision and speed. Their non-contact nature and clean finish make them perfect for tasks that need detail and consistency. Whether it’s sheet metal, plastic, or intricate design work—laser CNC machines get the job done right.