Many engineers hear the term “3-axis CNC” but still wonder what it really means. Is it basic? Is it outdated? Or is it still powerful?

A 3-axis CNC machine moves the cutting tool along three axes—X, Y, and Z—to shape parts from solid material based on computer instructions.

This machining setup is one of the most widely used formats in modern manufacturing. Let’s look deeper at how it works and why it remains a key tool in the industry.

How does a 3-axis CNC machine work?

When people hear “CNC,” they often picture complex machines. But 3-axis systems follow a simple, logical motion pattern.

A 3-axis CNC machine works by moving the tool or workpiece in three straight-line directions—left-right (X), forward-backward (Y), and up-down (Z).

These three directions allow the tool to cut flat surfaces, drill holes, and mill edges. Everything happens layer by layer, based on programmed coordinates.

Motion Principles

The machine reads a digital code (like G-code) that defines movement instructions. The motors and ball screws drive the spindle and table across each axis. Here’s how each axis moves:

- X-axis: Moves left to right

- Y-axis: Moves front to back

- Z-axis: Moves up and down

System Components

| Machine Part | Function |

|---|---|

| Spindle | Rotates the cutting tool |

| Worktable | Holds the material |

| Linear Guide Rails | Guide axis movement |

| Stepper/Servo Motors | Drive each axis |

| CNC Controller | Executes the programmed tool path |

This setup allows manufacturers to cut 2D and 2.5D shapes efficiently. However, because the tool cannot tilt or rotate, it can’t reach complex undercuts or sidewalls.

Still, for many tasks, 3-axis machining is fast, accurate, and cost-effective. It's often the first CNC platform chosen by shops starting automation.

Why is a 3-axis CNC machine popular?

Some people think newer means better. But 3-axis machines are still everywhere in industry. Why?

3-axis CNC machines are popular because they are simple to operate, affordable to maintain, and ideal for machining flat or prismatic parts.

These machines strike a balance between flexibility, cost, and ease of programming. They fit well in both low-volume and mass-production setups.

Key Benefits

1. Ease of Use

The programming is easier compared to 4- or 5-axis systems. Operators can use 2D CAD/CAM files, reducing setup and debugging time.

2. Cost Efficiency

They require fewer moving parts than multi-axis machines. This keeps maintenance and repair costs lower.

3. Widespread Compatibility

They work with standard fixtures, cutting tools, and materials. This reduces the need for custom tooling.

4. Scalable for Production

Whether making 10 parts or 10,000, the same machine can handle repeat jobs efficiently.

Comparison Table: 3-Axis vs 5-Axis CNC

| Feature | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Motion Range | X, Y, Z | X, Y, Z + A, B (tilt & rotation) |

| Programming Complexity | Low | High |

| Machine Cost | Lower | Higher |

| Setup Time | Short | Longer |

| Best For | Flat parts, simple holes | Complex 3D surfaces |

Many companies start with 3-axis machines before moving to advanced systems. They serve as the workhorse for day-to-day parts manufacturing.

Which parts are best suited for 3-axis CNC?

Not all parts need 5-axis complexity. Many can be made faster and cheaper using a simpler method.

3-axis CNC machines are best for parts with flat surfaces, straight edges, shallow cavities, slots, and drilled holes.

These machines cut accurately in three directions but can’t reach areas hidden from the top. So, ideal parts don’t need undercuts or deep side access.

Examples of Good 3-Axis CNC Parts

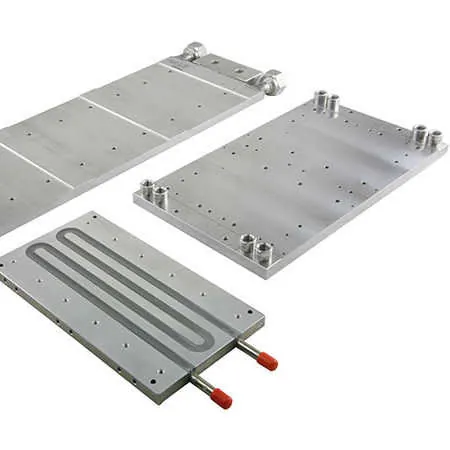

-

Base Plates and Brackets

Flat metal sheets with drilled holes and edge slots. -

Heat Sinks

Extruded aluminum blocks milled on top and sides. -

Valve Covers

Rectangular enclosures with shallow pockets and bolt holes. -

Mounting Frames

Cut from sheets or blocks with straight contours. -

Control Panels

Plastic or metal faces cut for buttons and connectors.

Geometry Considerations

| Feature Type | 3-Axis Suitability |

|---|---|

| Flat Faces | Excellent |

| Vertical Walls | Good |

| Deep Cavities | Limited |

| Undercuts | Not possible |

| Complex Angles | Not possible |

Designers often break complex parts into smaller components. Each one fits the 3-axis range, then gets assembled into the final product.

This modular approach keeps production affordable and machine utilization high.

Where are 3-axis CNC machines applied?

Some people think 3-axis machines are only for small shops or hobbyists. But they’re used across industries, every day.

3-axis CNC machines are widely applied in aerospace, automotive, electronics, medical, consumer goods, and general manufacturing sectors.

These machines are reliable for large batch jobs and repeat parts. Their low cost per part makes them ideal for price-sensitive applications.

Industry Applications

Aerospace

Used to make structural brackets, plates, and support blocks. Many are aluminum or titanium, shaped in 2D profiles.

Automotive

Produce engine mounts, dashboard frames, and cooling plates. These parts don’t need advanced surface machining.

Electronics

Cut plastic and aluminum enclosures, heat sinks, and control panels. Quick to set up, with consistent part quality.

Medical

Used for surgical trays, machine enclosures, and calibration blocks.

Furniture and Fixtures

Machine wood, MDF, and aluminum profiles into handles, panels, or supports.

Industry Use Table

| Industry | Common 3-Axis CNC Parts |

|---|---|

| Aerospace | Brackets, backplates |

| Automotive | Covers, holders |

| Electronics | Chassis, panels |

| Medical | Frames, fixtures |

| Furniture | Flat-pack parts |

3-axis machines also support educational programs and prototyping labs. Their lower cost and fast learning curve make them a go-to tool for first-run designs.

Conclusion

A 3-axis CNC machine is a powerful and flexible tool for many manufacturing needs. It follows three simple directions to cut precise shapes, making it ideal for most flat or shallow parts. Despite newer technologies, 3-axis systems still play a major role in modern production.