In many shops, milling feels slow or unpredictable. That makes parts inconsistent and wastes time.

A CNC miller uses computer control to drive the cutting tool. It follows digital designs to produce parts with high precision and repeatability. CNC milling cuts faster and with more accuracy than manual machines.

That precision matters when parts must fit tight tolerances or repeat many times. Below I explain what makes a CNC miller special, how people use it, and why it matters for modern manufacturing.

How does a CNC miller differ from a standard milling machine?

Imagine a machine that needs constant hand guidance. A traditional milling machine works like that. Moving a handwheel changes cutter position. Results depend on the operator. Mistakes or small slips cause errors or uneven parts.

A CNC miller replaces the handwheel with a computer. The cutter moves under digital commands. That makes cuts precise, repeatable, and less reliant on operator skill. You get consistent results no matter who runs the machine.

Key Differences Between CNC and Manual Milling

| Feature | Manual Milling | CNC Milling |

|---|---|---|

| Control | Hand-operated wheels | Computer-controlled axes |

| Accuracy | Limited by hand precision | High precision, tolerance to 0.01 mm |

| Repeatability | Hard to duplicate parts | Identical parts every time |

| Operator skill | High skill needed | Less skill needed for similar output |

| Speed | Slower for complex shapes | Fast, especially for complex cuts |

| Production Volume | Low to medium | Medium to high |

In a manual mill, the cutter moves when someone turns wheels. That means every cut depends on human steadiness. For complex shapes or repeated parts, that brings inconsistency. A CNC miller removes that problem. It reads a digital program, then moves exactly as told. That ensures identical parts, even over long runs.

CNC milling also allows more complex shapes. A manual mill needs skill to carve curves or angled cuts. CNC mills can follow complicated paths precisely. That unlocks design freedom. It also reduces waste. Since dimensions are accurate, parts fit together better. That lowers scrap rates.

Maintenance and setup differ. A manual mill needs careful alignment and manual adjustments. CNC mills need proper calibration and programmed toolpaths. That demands different skills. Yet once set up, CNC machines run reliably. That saves time and reduces human error.

Because of this difference, CNC millers often serve mass production or precision parts manufacturing. They suit industries where many identical parts are needed. They also work when tight tolerances matter. In contrast, manual milling stays useful when only one or a few unique parts are needed — or when budget is tight.

Overall, the difference is like writing with a typewriter vs a computer. A computer replicates text exactly. A typewriter depends on hand steadiness. CNC milling brings the same consistency to machining.

What are the applications of a CNC miller?

Sometimes design demands shapes that are hard to mold or cast. Companies need parts with complex surfaces or pockets. They need high precision. They need to make those parts over and over. That is when they turn to CNC milling.

People use CNC millers for parts needing accuracy, complex shapes, or batch production. Typical uses include prototype development, mechanical parts, housing components, and custom tooling. CNC milling handles both single prototypes and long runs.

Common Uses of CNC Milling in Manufacturing

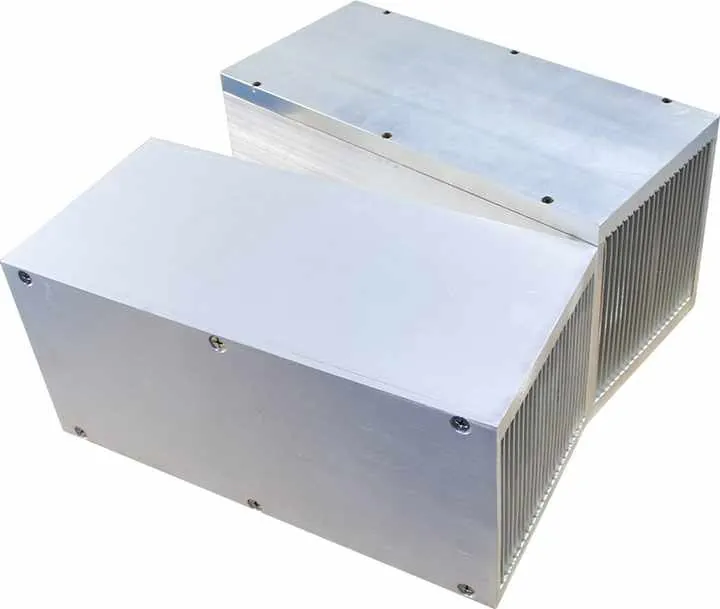

CNC milling shines when designers need to transform a CAD model into a real part. For example, one can mill a metal block into a bracket, a cover, or a fixture. The shapes can include holes, pockets, slots, angled faces, threads, even curves. Complex parts for machines, enclosures, and tools often come from CNC mills.

Prototyping is a major application. Engineers often need a working sample quickly. A CNC miller can turn a digital model into a solid prototype within hours. This helps test fit, form, and function before committing to expensive molds or casting. That saves money and reduces risk.

Small to medium production runs are also common. If a company needs hundreds or thousands of units but not enough to justify a mold, CNC milling is ideal. It delivers consistent quality without high upfront tooling cost. Manufacturers in automotive aftermarket, industrial parts, or aerospace components often rely on CNC mills for those runs.

Custom tooling and fixtures benefit too. In many factories, custom jigs, clamps, or holding fixtures must be made. CNC milling makes these accurately. The fixtures reliably hold parts in place during welding or assembly. That improves quality and speeds assembly.

Another application is repair and modification. When a legacy machine part is obsolete, shops can reproduce it with CNC milling. They reverse‑engineer the shape and produce a replacement part. That extends machine life without designing a new tool or mold.

Finally, CNC milling supports research and development. Labs and technical teams use it to test new designs. Because CNC machines handle many materials, they can produce parts from aluminum, steel, plastics, or composite materials. This flexibility is useful when trying new materials or part geometries. CNC milling is versatile.

Overall, CNC mills help bridge between design and production. They make complex parts, customized tools, and short runs. That flexibility makes them a workhorse in many manufacturing sectors.

Which industries use CNC milling machines?

Some industries build simple parts. Others build high‑precision, complex pieces. CNC milling fits where precision, repeatability, or complexity matters. That includes aerospace, medical, automotive, electronics, and more.

Industries that use CNC milling include aerospace, medical devices, automotive, electronics, tooling, and prototyping firms. These industries value accuracy, traceability, and consistent quality.

Industries and Their Use Cases

Here is a table of industries and typical CNC milling applications:

| Industry | Typical CNC Milling Use Cases |

|---|---|

| Aerospace | Structural components, housings, brackets, fittings |

| Medical Devices | Surgical instruments, implants, prosthetic parts |

| Automotive | Engine parts, custom components, tooling fixtures |

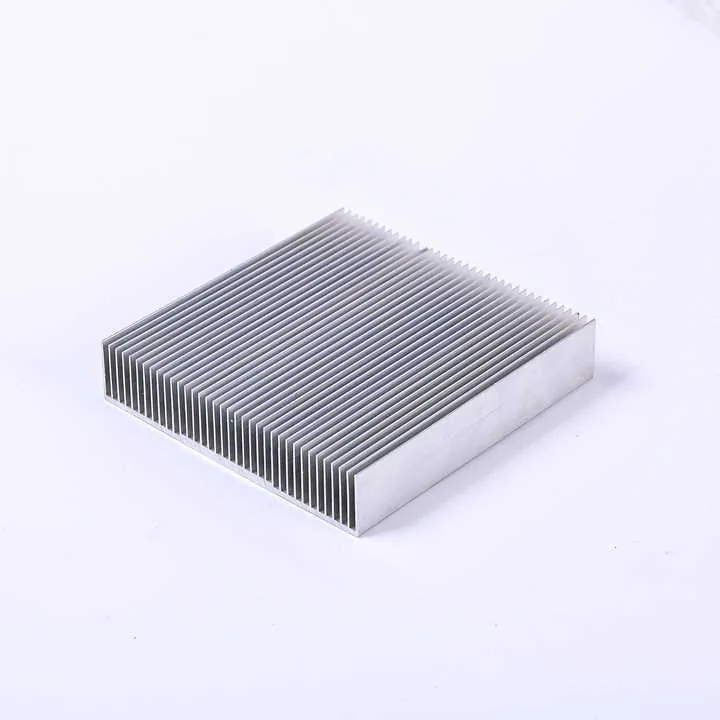

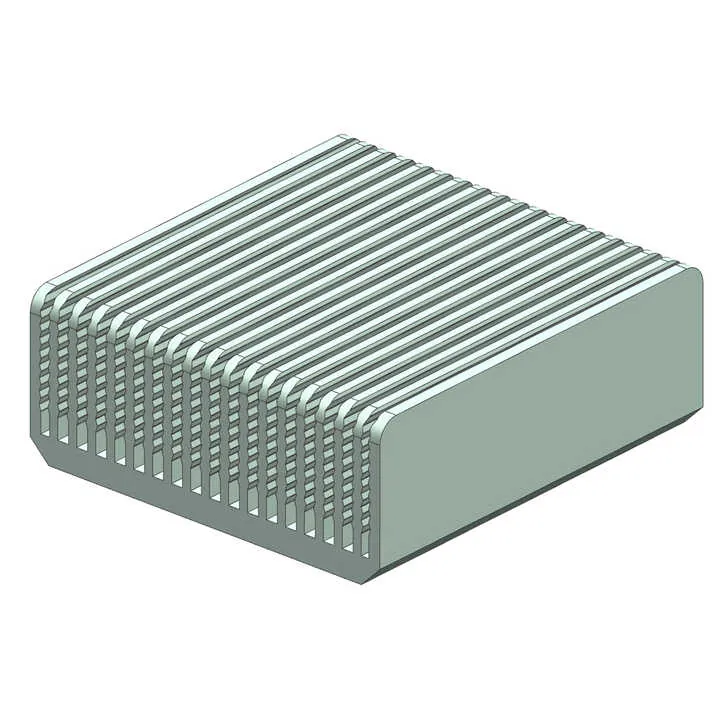

| Electronics | Housings, heat sinks, chassis for devices |

| Industrial Machinery | Gears, brackets, frames, molds, machine parts |

| Prototyping & R&D | Prototype parts, custom fixtures, small batch runs |

In aerospace, parts must meet tight tolerances. CNC milling delivers that. So aerospace firms get wing fittings, housings, mounts from CNC mills. Medical device makers need clean, precise parts. They use CNC milling to make surgical tools or implant prototypes. Automotive companies use CNC milling for custom engine parts, small‑volume components, or high‑precision fixtures. Electronics firms use milling to make enclosures, heat sinks, or custom chassis. Industrial machinery builders need frames, molds, or machine parts. CNC milling offers flexibility and precision. Prototyping labs rely on CNC milling to quickly turn CAD designs into physical parts.

Many small firms benefit too. They may not have budgets for mass production molds. But they need accurate parts for custom machines or equipment. CNC milling gives them a way to build without high tooling costs.

In addition, firms working on custom batches or modifications use CNC milling. When a standard part is no longer available, shops can remake it. That saves cost and extends life of equipment.

Because of wide material support, CNC milling supports many sectors. That includes metal processing, plastic machining, composite materials. Due to computer control, it ensures uniform quality and repeatability. That matters for regulated industries like aerospace and medical.

What materials are best suited for CNC milling?

Not all materials work the same on milling machines. Some cut easily, others wear tools fast. Some need coolants, some do not. The right material helps achieve clean cuts, long tool life, and accurate parts.

Metals like aluminum, mild steel, stainless steel, brass and plastics such as nylon or ABS often work best. Soft metals and machinable plastics give good surface finish and dimensional accuracy with CNC mills.

Material Suitability for CNC Milling

| Material Type | Suitability | Notes |

|---|---|---|

| Aluminum | Excellent | Easy to cut, good finish, widely used |

| Mild Steel | Very Good | Strong parts, needs coolant to avoid heat |

| Stainless Steel | Good but tough | Requires sharp tools, may cut slower |

| Brass | Very Good | Soft, good finish, minimal tool wear |

| Plastics (e.g. Nylon, ABS) | Good | Light parts, easy cutting, careful on heat |

Soft metals and plastics work well because they cut smoothly and do not stress tools too much. Aluminum is a top choice. It cuts quickly and leaves smooth surfaces. That makes it ideal for housings, fixtures, heat sinks, and prototypes. Mild steel offers strength and durability. It suits parts that will face mechanical stress. However, it generates heat when cut quickly. So coolants are helpful to maintain tool life and prevent warping.

Stainless steel can be milled, but it is harder. It wears tools more quickly. It may cut slower and sometimes needs special tooling. For parts needing corrosion resistance or high strength, stainless steel is used. The tradeoff is speed and tool wear.

Brass is soft and easy to machine. It gives good finish and seldom causes tool damage. It suits decorative parts, fittings, and precision components. Plastics like Nylon or ABS work when light weight or insulation matters. They mill fast and require less force. They suit enclosures, insulating parts, or prototype models. However, plastics can melt or deform without correct feed rate and cooling. So proper settings matter.

Harder materials like titanium, hardened steel, or exotic alloys can be milled too. But they demand advanced machines, slow speed, special tools, and careful cooling. For typical shops, metals under moderate hardness and machinable plastics remain the best fit.

In short, material choice depends on the part’s need: strength, weight, surface finish, or insulation. CNC milling works best when the material cuts cleanly under rotating tools, yet leaves a quality surface. That often points to aluminum, mild steel, brass, or machinable plastics.

Conclusion

CNC milling turns digital designs into precise, repeatable parts. It beats manual milling when accuracy, repeatability, or batch production matters. People trust it in aerospace, medical, automotive, and many other fields. For best results, choose materials like aluminum, mild steel, brass or plastics. CNC milling brings flexibility and control to modern manufacturing.