CNC turning and milling are two essential processes in modern machining that allow manufacturers to create highly precise parts. But what exactly are these processes, and how do they work together to produce complex components?

CNC turning and milling are machining processes that use computer-controlled machines to cut and shape materials like metal, plastic, or wood. Turning involves rotating the workpiece, while milling involves moving the cutting tool along various axes to shape the material.

Understanding how CNC turning and milling complement each other is crucial for grasping their importance in manufacturing. These processes are often used in tandem to create parts that require both rotational and linear movements. Let’s explore how these processes work together and why they’re so important in today’s industries.

How do CNC turning and milling processes work together?

CNC turning and milling work together by combining rotational cutting with linear cutting to produce complex parts. CNC turning shapes the outside of a rotating workpiece, while CNC milling shapes the material using a stationary cutting tool.

While CNC turning focuses on rotating the workpiece to shape it, CNC milling uses rotating tools to cut into the material. In many cases, both processes are used on the same machine or on separate machines to complete a part in a single setup. This allows for the creation of highly detailed and accurate components, such as shafts, gears, and housings.

The Role of CNC Turning in the Process

CNC turning is especially useful for creating cylindrical parts or parts with symmetrical features. During this process, the workpiece is mounted on a rotating spindle, and the cutting tool moves along the length of the material to shape it. The rotation allows for high-precision cuts, making it ideal for producing parts such as pins, rods, and bushings.

The Role of CNC Milling in the Process

CNC milling, on the other hand, is more versatile and can handle a variety of complex geometries. The cutting tool in CNC milling moves along multiple axes (usually three or more), allowing it to carve out intricate shapes and features. Milling is commonly used to create flat surfaces, cavities, and holes, and it is often employed for parts that need detailed contours or precise cuts.

How They Complement Each Other

When combined, CNC turning and milling can create parts that have both cylindrical and detailed geometric features. For example, a part might be turned to create a smooth cylindrical surface and then milled to create complex internal features, such as slots or grooves. Using both processes ensures a high level of accuracy and reduces the need for multiple setups, saving time and reducing errors.

What parts are created using CNC turning and milling?

CNC turning and milling are used to create a wide variety of parts across many industries. Some common examples include shafts, gears, housings, and complex components used in automotive, aerospace, and medical industries.

Parts Created by CNC Turning

- Pins and Shafts: These are common turned parts that are used in many machines. The rotating motion of the workpiece in CNC turning is ideal for creating these long, cylindrical parts with smooth surfaces.

- Bushings and Sleeves: These parts often have a cylindrical shape and are commonly used in mechanical assemblies to reduce friction between parts.

- Rings and Discs: These parts are commonly used in industries like automotive and aerospace. CNC turning can efficiently produce these parts in large quantities.

Parts Created by CNC Milling

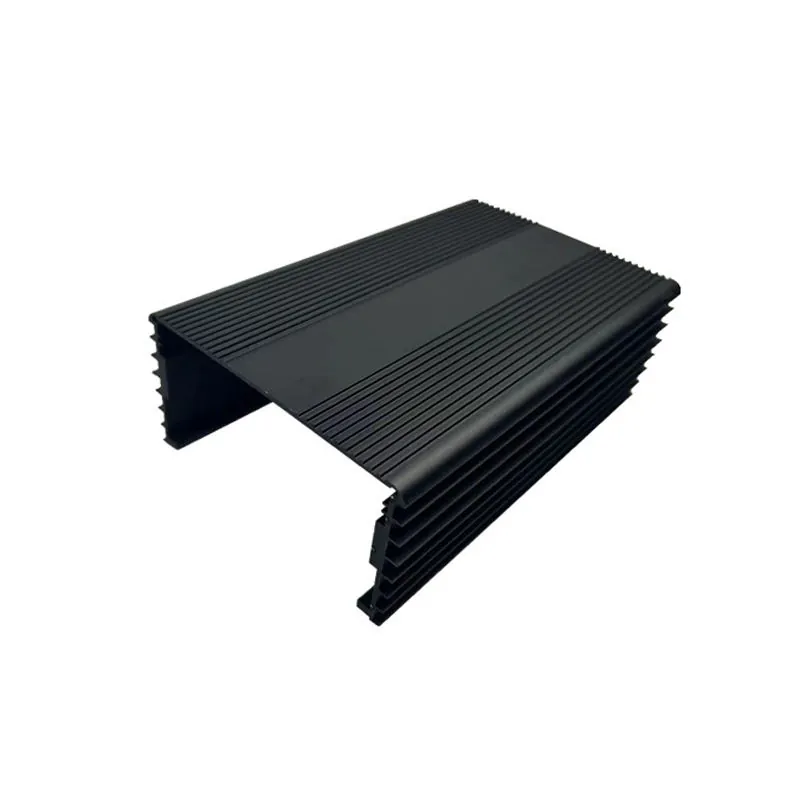

- Housings and Enclosures: These parts require precise internal and external features, which can be easily produced with CNC milling.

- Gears and Pulleys: The intricate tooth patterns of gears and pulleys are often created using CNC milling. The ability to mill the teeth in precise locations ensures that the gears mesh correctly in mechanical systems.

- Complex Components: Any part that requires detailed geometries, such as holes, slots, or intricate surface features, is typically created using CNC milling.

Parts Created by Both Processes

Some parts require both turning and milling, especially when they feature both rotational symmetry and complex details. For example, a part might be turned to shape its basic structure and then milled to create features such as keyways, threads, or holes.

What is the difference between CNC turning and CNC milling?

The main difference between CNC turning and CNC milling lies in how the material is cut. CNC turning involves rotating the workpiece, while CNC milling involves rotating the cutting tool.

CNC Turning

- Workpiece Rotation: In CNC turning, the workpiece is held in place and rotated while the cutting tool moves along the material’s surface. This process is ideal for cylindrical parts and symmetrical shapes.

- Cutting Tool Movement: The cutting tool in turning typically moves along the length of the rotating workpiece, allowing it to shape the material precisely.

- Best for: Parts with cylindrical shapes, such as rods, pins, bushings, and shafts.

CNC Milling

- Tool Rotation: In CNC milling, the cutting tool rotates and moves along multiple axes to cut into the workpiece. The workpiece can be stationary or moved in various directions.

- Cutting Tool Movement: The tool can move horizontally, vertically, and diagonally, making milling more suitable for creating detailed shapes, cavities, and features.

- Best for: Parts with complex geometries, flat surfaces, and detailed internal features like holes and grooves.

Key Differences

| Feature | CNC Turning | CNC Milling |

|---|---|---|

| Movement | Rotating workpiece, fixed tool | Rotating tool, stationary workpiece |

| Best For | Cylindrical and symmetrical parts | Complex shapes and detailed features |

| Precision | Ideal for high-precision cylindrical cuts | Ideal for detailed cuts and shapes |

| Tool Movement | Moves along the length of the workpiece | Moves along multiple axes to cut intricate shapes |

What industries commonly use both CNC turning and milling?

Many industries, including aerospace, automotive, medical, and manufacturing, rely on both CNC turning and milling to produce parts that meet their exact specifications.

Aerospace Industry

In the aerospace sector, precision is critical. Parts such as turbine blades, housing components, and engine parts are often produced using both CNC turning and milling. The combination of rotational and linear cutting allows manufacturers to create complex components that must meet strict safety and performance standards.

Automotive Industry

The automotive industry also benefits from both CNC turning and milling, especially when producing engine components, gears, shafts, and transmission parts. These components require both precise cylindrical features and intricate internal designs, which is why both machining processes are often employed.

Medical Industry

The medical field requires high-precision components like implants, surgical instruments, and prosthetics. These parts are often made using a combination of CNC turning and milling, ensuring that each piece meets exact specifications for fit and function.

Manufacturing and Industrial Sectors

From machinery components to housings and gears, the manufacturing and industrial sectors rely heavily on CNC turning and milling to produce parts that are durable, precise, and capable of handling heavy-duty operations.

Conclusion

CNC turning and milling are complementary processes that play a crucial role in the manufacturing industry. Together, they allow for the creation of both simple and complex parts with a high degree of accuracy. Whether it’s in aerospace, automotive, medical, or other industries, these processes help ensure that parts are made efficiently and to exact specifications.