Sourcing the right CNC machine can be overwhelming, especially when dealing with complex parts. Let’s explore the benefits of 5-axis CNC machining and how it can transform your production process.

A 5-axis CNC machine offers unmatched precision and versatility, making it ideal for creating complex parts with high accuracy and efficiency.

CNC machining has evolved significantly, and 5-axis machines have become crucial in industries requiring intricate, high-precision parts. But what makes them different from traditional CNC machines, and why are they preferred for certain applications? Let’s dive into how 5-axis machines work and their advantages.

How Does a 5-Axis CNC Machine Function?

A 5-axis CNC machine works by moving the tool or the workpiece along five different axes simultaneously, allowing for complex and precise operations.

Unlike traditional 3-axis CNC machines that operate on the X, Y, and Z axes, a 5-axis machine includes two additional rotational axes. These axes allow the tool or the workpiece to rotate around multiple points, creating more complex cuts, angles, and intricate shapes.

The 5 Axes Explained

| Axis | Description |

|---|---|

| X-Axis | Left to right movement (horizontal). |

| Y-Axis | Forward and backward movement (horizontal). |

| Z-Axis | Vertical movement (up and down). |

| A-Axis | Rotates around the X-axis (tilting the workpiece). |

| B-Axis | Rotates around the Y-axis (tilting the workpiece further). |

The addition of these two rotary axes enables the machine to approach the workpiece from various angles, which makes it perfect for intricate designs. This function reduces the need for multiple setups and increases the overall precision of the operation.

Why Are 5-Axis CNC Machines Preferred for Complex Parts?

5-axis CNC machines are ideal for complex parts because they can achieve high precision and handle multi-directional cuts, which traditional machines cannot perform as efficiently.

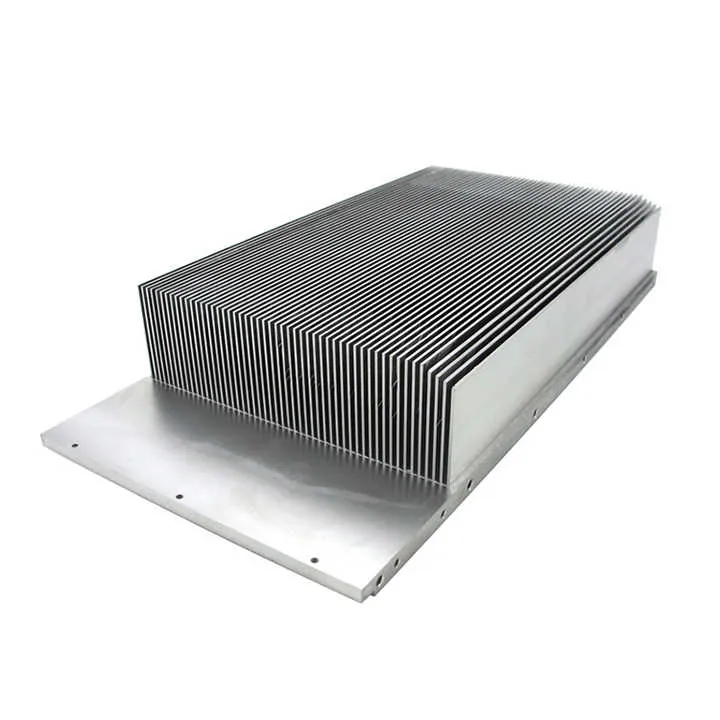

When working with parts that have complicated geometries, the flexibility and capability of 5-axis CNC machining become essential. These machines can perform cuts from almost any direction, drastically reducing the number of setup changes and increasing efficiency.

Key Advantages for Complex Parts

- Multi-Angle Machining: With the ability to approach the workpiece from five different angles, 5-axis machines make it easier to create complex parts in one setup.

- Precision: The reduced need for repositioning the part reduces errors and inconsistencies, making these machines ideal for high-precision parts.

- Reduced Time: Fewer setups mean faster production times, making 5-axis CNC machining more efficient for complex parts.

The ability to handle such complexity makes 5-axis CNC machines a go-to for industries requiring intricate details and tight tolerances.

Which Industries Use 5-Axis CNC Machines?

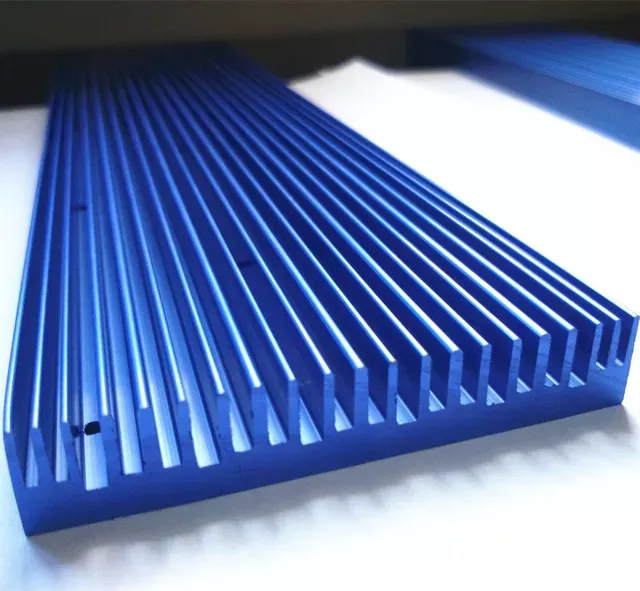

5-axis CNC machines are commonly used in industries that require precision, complexity, and efficiency in their manufacturing processes.

The versatility of 5-axis CNC machining makes it applicable across a variety of industries. It is particularly beneficial for sectors that need high-precision and complex parts.

Industries That Benefit from 5-Axis CNC Machining

| Industry | Application |

|---|---|

| Aerospace | Manufacturing complex airframe parts and engine components. |

| Automotive | Creating detailed molds, engine components, and prototypes. |

| Medical Devices | Manufacturing implants, surgical tools, and medical instruments. |

| Defense | Producing components for military and defense technologies. |

| Tooling & Molds | Creating molds for casting, injection molding, and tooling. |

These industries rely on the advanced capabilities of 5-axis CNC machines to meet strict tolerances and high-quality standards, ensuring parts function efficiently and safely.

Where Does 5-Axis Machining Offer Significant Advantages?

5-axis machining is ideal for operations that require intricate, multi-faceted cuts with high precision, such as aerospace, automotive, and medical device manufacturing.

One of the primary advantages of 5-axis machining is the ability to perform multi-directional cuts in a single operation, which minimizes setup time and increases precision. It is particularly valuable in applications where parts have complex shapes, tight tolerances, or require high surface finishes.

Key Advantages of 5-Axis Machining

- Reduced Tool Changes: The ability to access multiple angles reduces the need to reposition or re-clamp the workpiece, which in turn reduces the number of tool changes.

- Improved Accuracy: Fewer setup changes lead to higher accuracy and a reduced risk of errors in multi-step machining processes.

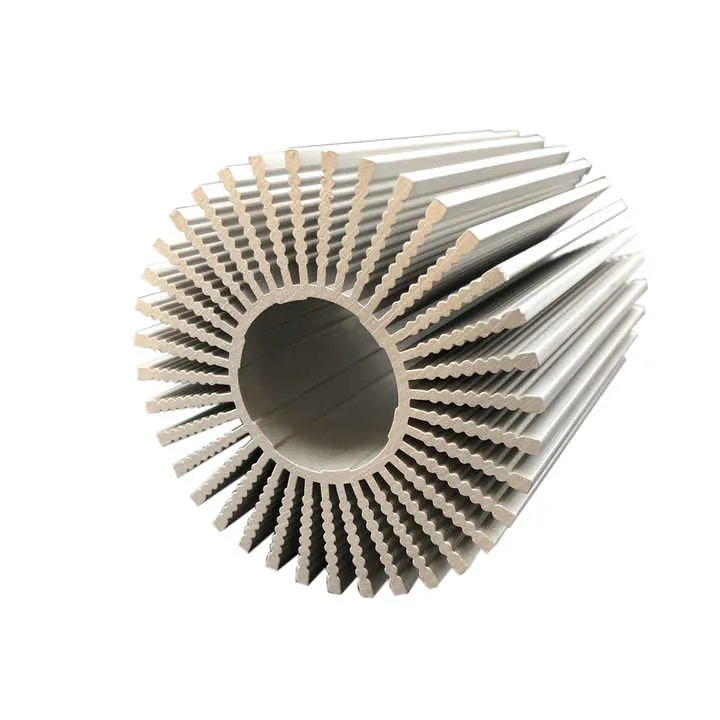

- Complex Geometries: For parts with complicated shapes, such as turbine blades, 5-axis machining is essential for creating the precise angles and contours needed.

5-axis machining is not only more efficient but also provides the ability to produce parts that would be difficult or impossible with traditional machines.

Conclusion

5-axis CNC machining offers a high degree of precision, flexibility, and efficiency, making it the go-to solution for industries that require complex, high-quality parts. With its ability to handle intricate geometries and reduce the time spent on multiple setups, it’s clear why so many industries rely on 5-axis CNC machines for their manufacturing needs.