When you need holes drilled with perfect accuracy, traditional tools often fall short. Precision, speed, and consistency are no longer optional—they're expected.

CNC drilling is an automated process that uses computer-controlled machines to drill holes with extreme precision and repeatability, making it ideal for industrial and high-volume applications.

Unlike manual drilling, CNC drilling follows pre-programmed instructions that guide the tool path, depth, and speed. This allows for intricate designs, fast turnaround, and minimal human error.

How does CNC drilling differ from traditional drilling?

When accuracy matters, relying on human control alone can introduce errors. Manual drilling may get the job done, but it often lacks the precision needed for modern manufacturing.

CNC drilling differs from traditional drilling by replacing manual control with computer programming, which ensures consistent hole placement, depth, and speed for every part produced.

Traditional drilling relies on human judgment and strength. The operator must hold the tool steady, control feed rate, and measure depth manually. While skilled workers can produce decent results, inconsistencies are common, especially in high-volume jobs.

CNC (Computer Numerical Control) drilling, on the other hand, operates based on digital instructions. Every movement of the drill is pre-determined by a CAD/CAM file. This eliminates guesswork. Whether you're making one part or ten thousand, every hole will be identical.

Key differences at a glance

| Feature | Traditional Drilling | CNC Drilling |

|---|---|---|

| Control Method | Manual | Computerized |

| Accuracy | Moderate | High |

| Speed | Depends on operator | Consistent and fast |

| Repeatability | Low | Very high |

| Skill Level Required | High | Moderate (more in setup) |

| Complex Hole Patterns | Difficult to achieve | Easily programmed |

CNC drilling is especially useful when you need holes in complex patterns or unusual angles. Instead of using jigs and measuring tools, the machine interprets code and executes it without deviation. It's also less tiring for operators. Once set up, the process is mostly hands-off. That reduces the risk of injury and boosts productivity.

Why is CNC drilling preferred for precision?

In projects where even a slight error can lead to failure, conventional methods often fall short. CNC drilling offers a level of control and precision that manual techniques simply cannot match.

CNC drilling is preferred for precision because it follows digital instructions with no variation, allowing for exact hole placement and consistent quality across large production runs.

Precision in manufacturing means more than just accurate parts—it means fewer errors, reduced waste, and better performance. CNC drilling uses G-code programming to define every movement of the tool. That includes speed, depth, and location.

When all parameters are precisely controlled, the result is a clean, accurate hole every time. There's no wobbling, over-drilling, or misalignment. For industries like aerospace, medical devices, and electronics, even a fraction of a millimeter matters. CNC drilling can hold tolerances as tight as ±0.01 mm.

Common features supporting high precision

| CNC Feature | Role in Precision |

|---|---|

| Servo motors | Maintain exact tool position |

| Linear guides | Smooth, controlled motion |

| Tool wear compensation | Adjusts for tool degradation |

| Probe systems | Automatically checks dimensions |

| Closed-loop feedback | Corrects deviations in real time |

Another advantage is consistent performance across batches. Whether you're drilling 5 or 5,000 holes, each one will match the original spec. That reduces inspection time and lowers the chance of returns or rework.

In precision-heavy sectors, it's not just about making parts that fit—it's about making them last, perform, and integrate seamlessly into larger systems. CNC drilling ensures that kind of reliability.

Which materials are commonly drilled using CNC machines?

Choosing the right material for drilling is only half the challenge. Making clean, accurate holes in that material requires both the right tools and the right technique.

CNC machines can drill a wide range of materials including aluminum, steel, plastics, composites, and even wood, depending on the tooling and machine settings.

CNC drilling is incredibly versatile. The type of material doesn't matter as much as choosing the correct drill bit, speed, and feed rate. The most common materials include:

1. Metals

- Aluminum: Soft, easy to drill, and commonly used in construction and electronics.

- Steel: Requires tougher tools and lower speeds to avoid overheating.

- Stainless steel: Needs coolant and specific bits to reduce wear.

2. Plastics

- ABS, PVC, Acrylic: Drill easily, but must be handled gently to avoid melting.

- Nylon, Polycarbonate: Need sharp tools and slower feed rates to avoid cracking.

3. Composites

- Carbon fiber and fiberglass: Require special drills to prevent fraying or delamination.

- Phenolic materials: Often drilled with carbide tools for clean results.

4. Others

- Wood: Though less common in industrial settings, CNC routers often handle wood.

- Ceramics: Special diamond-tipped tools and slow speeds are used.

Each material has unique challenges. CNC systems allow you to adjust for those. For example, drilling through aluminum might need high speeds, while carbon fiber needs lower speeds and different drills. The ability to change settings instantly makes CNC ideal for multi-material workflows.

Tool life is also easier to manage. Because the machine knows how long a bit has been in use, it can flag when replacements are needed. That avoids sudden failures or bad cuts. The goal is always the same: clean holes, fast cycles, and minimal waste.

Where is CNC drilling commonly applied?

From tiny holes in circuit boards to thick metal plates for skyscrapers, CNC drilling finds a place in nearly every industry that requires precision fabrication.

CNC drilling is widely used in industries like aerospace, automotive, electronics, construction, and medical manufacturing due to its accuracy, speed, and automation.

CNC drilling is not just for one niche. Its applications span across many industries, each with its own set of requirements and standards.

Major application areas

Aerospace

Planes require thousands of holes, all with strict tolerances. CNC drilling is used for:

- Airframe components

- Engine parts

- Interior paneling

Automotive

Cars contain hundreds of parts that must fit precisely. CNC is used to drill:

- Engine blocks

- Suspension systems

- Brake components

Electronics

Tiny, closely spaced holes are common in this sector. CNC drills:

- Printed Circuit Boards (PCBs)

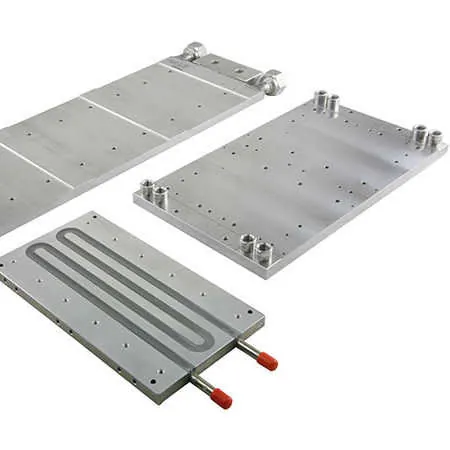

- Heat sinks

- Connectors

Medical devices

Devices must be sterile and ultra-precise. CNC drilling helps with:

- Surgical instruments

- Implants

- Diagnostic equipment housings

Construction

Structural components often require drilling into heavy materials. CNC is used for:

- Steel beams

- Curtain walls

- Prefabricated panels

Emerging sectors

As industries move toward automation, CNC drilling is expanding into new areas:

- Renewable energy (e.g., solar panel frames)

- Robotics

- 3D printing support structures

Because of its flexibility, CNC drilling can be tailored to each job. Once the design is ready, switching from one application to another is just a matter of changing the code and the tool. That keeps downtime low and production high.

Conclusion

CNC drilling transforms the way holes are made—faster, cleaner, and more precise. From metal to plastic, from small parts to massive assemblies, it's the go-to choice for modern manufacturing.