Traditional cutting can be slow, uneven, and hard to repeat. But what if a computer could carve wood, plastic, and even aluminum with perfect accuracy?

A CNC router machine is a computer-controlled cutting tool that moves along multiple axes to carve or engrave materials like wood, plastic, foam, or soft metals.

It replaces manual tools like saws or routers and brings speed, accuracy, and repeatability to the job. In this article, we explore how it works, what it cuts, and where it’s used.

How does a CNC router machine work?

At first glance, a CNC router might look like a large printer or laser machine. But inside, it’s doing far more complex work.

A CNC router machine operates by following digital instructions to cut, carve, and shape material using a rotating cutting tool along X, Y, and Z axes.

The entire process starts with a computer. A design is created using CAD (Computer-Aided Design) software. This design is then converted into a CAM (Computer-Aided Manufacturing) file, which contains toolpaths—the exact movements the router should follow.

The CNC controller reads this code and moves the router’s spindle across three directions:

- X-axis (left and right)

- Y-axis (forward and back)

- Z-axis (up and down)

The spindle spins a cutting bit at high speed. As the spindle moves, the bit carves out the material to match the design.

Basic parts of a CNC router:

| Part | Function |

|---|---|

| Spindle | Rotates the cutting tool |

| Table | Holds the workpiece |

| Stepper/Servo Motors | Move the spindle in X, Y, Z directions |

| Controller | Translates design files into movement |

| Frame | Supports the machine’s structure |

Most CNC routers also have a dust collection system to keep the workspace clean and safe. Some even have automatic tool changers, allowing the machine to switch between different bit types during one job.

Thanks to this automation, CNC routers can work faster than manual tools, and with greater accuracy—even on complex designs.

Why is a CNC router used in woodworking?

Wood is one of the oldest building materials. So why add high-tech machinery to the process?

CNC routers are used in woodworking to achieve detailed cuts, consistent shapes, and faster production without sacrificing quality.

Traditional woodworking depends on the skill of the craftsman. But with CNC routers, even beginners can create complex furniture parts, doors, or signs with ease.

Key benefits for woodworking:

1. Precision and repeatability

CNC routers can cut the same shape 100 times with no variation. This is ideal for cabinet parts or decorative moldings.

2. Complex designs

With the right bit, the machine can carve 3D reliefs, inlays, and intricate shapes that would take hours by hand.

3. Reduced waste

Since every cut is planned in software, mistakes are rare. That means fewer errors, less wasted material, and lower costs.

4. Time savings

Jobs that used to take a full day can now be finished in hours or minutes.

Let’s compare CNC routers with manual woodworking tools:

| Feature | Manual Tools | CNC Router |

|---|---|---|

| Accuracy | Depends on skill | ±0.05 mm |

| Repeatability | Hard to match pieces | Perfect every time |

| Speed | Slow | Fast |

| Complexity | Limited | High detail possible |

| Labor need | Skilled worker | One trained operator |

Wood shops use CNC routers to make everything from custom furniture to carved signs and architectural features. The machine handles both softwood and hardwood, and even engineered panels like MDF or plywood.

For those producing in volume or working on detailed designs, a CNC router is now an essential part of modern woodworking.

What materials can a CNC router machine process?

You might think it’s only for wood—but CNC routers are more versatile than that.

CNC router machines can cut and shape materials including wood, plastics, foam, composite panels, soft metals, and even carbon fiber sheets.

Let’s break down the common materials used with CNC routers:

1. Wood and wood-based panels

- Solid wood (pine, oak, walnut)

- Plywood

- MDF (medium-density fiberboard)

- Particleboard

2. Plastics

- Acrylic (PMMA)

- PVC

- Polycarbonate

- HDPE

3. Foams

- Polyurethane foam

- Polystyrene

- EVA foam

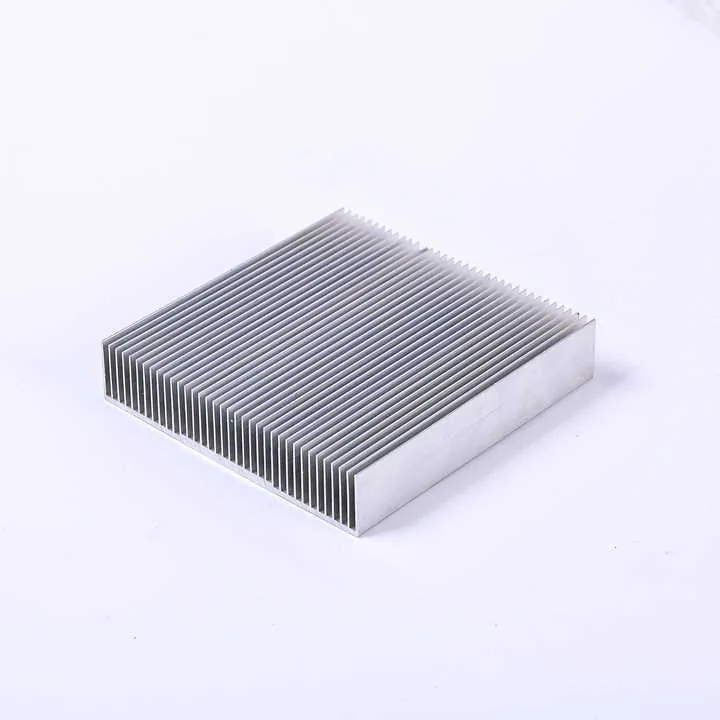

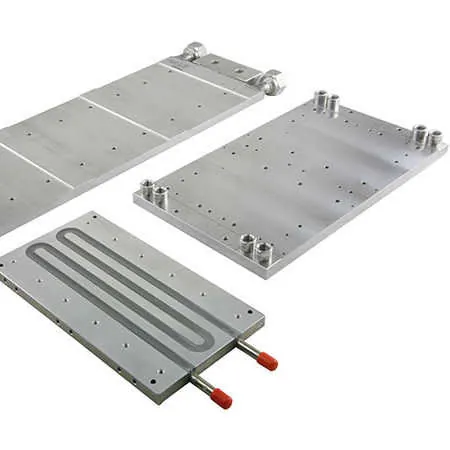

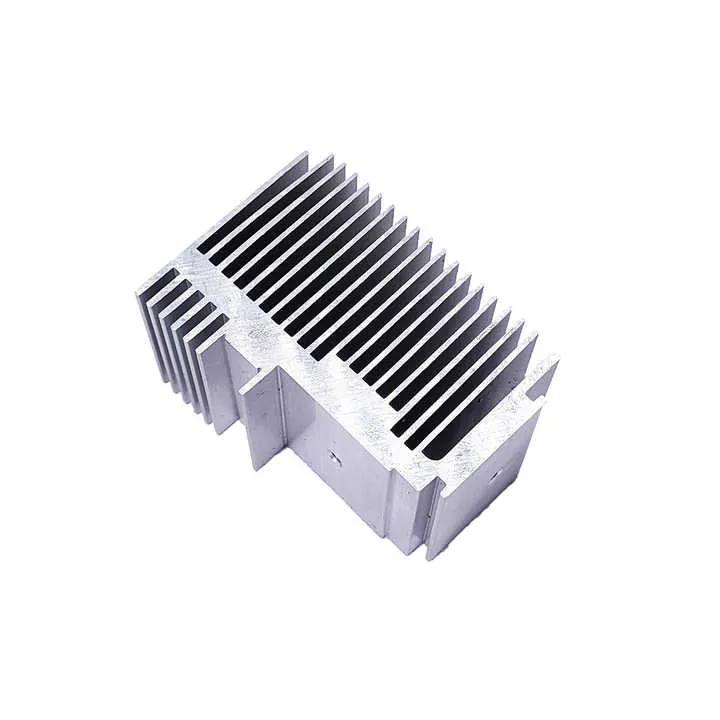

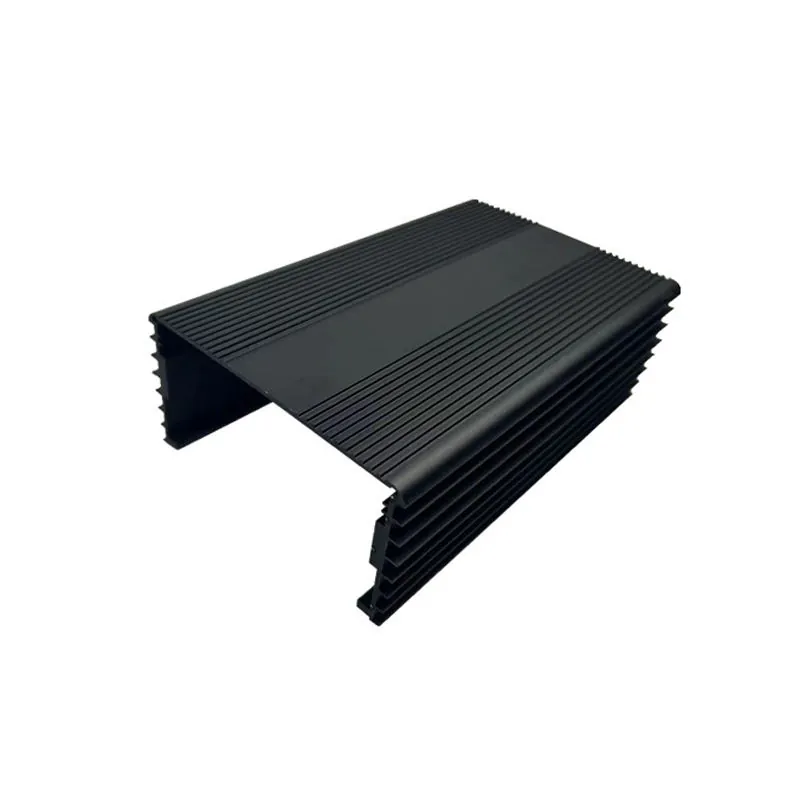

4. Soft metals

- Aluminum

- Brass

- Copper

5. Composites and others

- ACM panels (aluminum composite material)

- Carbon fiber sheets

- Fiberglass panels

The key is using the right cutting tool and settings. Softer materials need high-speed, low-force cuts. Harder ones like aluminum require slower speeds and lubrication to avoid tool wear.

Here’s a table to show ideal router settings by material:

| Material | Spindle Speed (RPM) | Feed Rate | Notes |

|---|---|---|---|

| MDF | 18,000–22,000 | Medium | Easy to cut |

| Acrylic | 15,000–20,000 | Slow-Medium | Avoid melting |

| Aluminum | 8,000–12,000 | Slow | Use coolant |

| Foam | 16,000–24,000 | Fast | Light cuts |

| PVC | 12,000–18,000 | Medium | Good ventilation needed |

Because CNC routers can handle so many materials, they’re used in many industries beyond woodworking. The flexibility also makes them ideal for prototyping and custom part production.

Where are CNC router machines most commonly used?

You might find one in a factory, a university lab, or even a home garage. Their use has expanded far beyond just cabinet shops.

CNC router machines are most commonly used in woodworking factories, sign-making shops, furniture production lines, schools, and prototyping labs.

Here are the most common places you’ll find these machines:

1. Furniture manufacturing

Large companies use CNC routers to mass-produce flat-pack furniture, cabinet doors, and decorative trims. They can cut panels, add grooves, and even drill holes in one operation.

2. Sign-making shops

Whether it’s a company logo, large letters, or 3D signs, routers handle materials like acrylic, PVC, or aluminum. With the right bits, the machine can create clean edges and sharp details.

3. Schools and maker spaces

Many technical schools and community workshops now have entry-level CNC routers. They help students and hobbyists learn design and manufacturing skills.

4. Prototyping and custom fabrication

When designers or engineers need a one-off part, a CNC router is perfect. It can quickly turn a design into a real object without needing expensive molds or tools.

5. Aerospace and automotive support shops

For trimming interior panels, cutting insulation, or making brackets from composite sheets, CNC routers save time and improve accuracy.

Because of this wide usage, routers come in many sizes:

- Desktop routers – for small parts and light materials

- Mid-size routers – for shops and schools

- Industrial routers – for 24/7 production with auto tool changers

These machines are changing how people design and build. Even small companies can now deliver complex, high-quality products with lower costs and faster turnaround.

Conclusion

CNC router machines bring speed, precision, and design freedom to industries like woodworking, signage, and custom part production. Whether cutting wood, foam, or aluminum, they help make better products faster—and with far fewer errors.