Most manufacturers struggle with surface finish and tight tolerances. Traditional grinding can't always deliver consistent precision. That’s where CNC grinding changes the game.

CNC grinding is a computer-controlled precision machining process used to shape and finish materials with high accuracy, often required in industrial and high-performance applications.

Many people still view grinding as a purely manual job. But today's CNC grinding machines are fast, repeatable, and extremely accurate. They offer advantages you can't get from manual methods.

How does CNC grinding work?

Even experienced machinists can find it hard to explain how CNC grinding works in detail. It involves more than just removing material. There's a system behind the precision.

CNC grinding works by using pre-programmed computer software to control the movement of grinding wheels across a part’s surface, producing accurate shapes and finishes.

CNC stands for Computer Numerical Control. In CNC grinding, the machine follows a program to move the grinding wheel with precision. The part is mounted on a work table or spindle. Motors and encoders guide the machine’s movement on multiple axes—typically X, Y, Z, and sometimes more.

Key components of a CNC grinding system

- Grinding wheel – The cutting tool made of abrasive particles.

- Workholding device – Holds the part firmly in place.

- CNC controller – The brain of the machine, interpreting the digital program.

- Coolant system – Prevents overheating during grinding.

The entire operation depends on a digital code. This code is generated from CAD models and loaded into the machine. Once the cycle starts, the machine runs automatically.

Process flow

| Step | Description |

|---|---|

| 1 | Load the part and secure it in the fixture. |

| 2 | Load the grinding program into the CNC controller. |

| 3 | Select and calibrate the grinding wheel. |

| 4 | Initiate the grinding cycle. |

| 5 | The machine finishes the part to the programmed specifications. |

CNC grinding can be used for both external and internal surfaces, flat or round shapes, and complex geometries. The level of precision it provides is often in the micron range, making it ideal for parts that require extreme accuracy.

What are the types of CNC grinding machines?

It’s easy to assume all grinding machines are the same. In reality, CNC grinding includes a range of machines, each with a different job.

There are several types of CNC grinding machines, including surface grinders, cylindrical grinders, centerless grinders, and tool and cutter grinders, each suited for specific applications.

Let’s explore these types in more detail.

1. Surface Grinders

These machines are used for flat surfaces. A spinning grinding wheel moves back and forth over a part. They're often used for molds, plates, and flat metal sheets.

2. Cylindrical Grinders

These are ideal for round parts like shafts or rods. The part spins while the wheel grinds the outer or inner diameter. They are commonly used in automotive or aerospace parts.

3. Centerless Grinders

No clamping required. Instead, the part is supported between two wheels. Centerless grinding is fast and good for mass production of small cylindrical parts.

4. Tool and Cutter Grinders

These machines sharpen tools or shape cutting parts. They're important in tool-making and mold manufacturing.

| Type of Machine | Best for | Special Feature |

|---|---|---|

| Surface Grinder | Flat surfaces | High surface finish |

| Cylindrical Grinder | Round or tubular parts | Precision rotation control |

| Centerless Grinder | High-volume cylindrical parts | No need for clamping or chucking |

| Tool and Cutter Grinder | Tool making and re-sharpening | Multi-axis, high-speed operation |

Some advanced grinding machines also combine functions—such as milling and grinding in one setup. This boosts efficiency for complex parts.

What materials can be ground using CNC machines?

Many people think grinding is only for metals. But that’s just part of the picture. CNC grinding works on a wide range of materials.

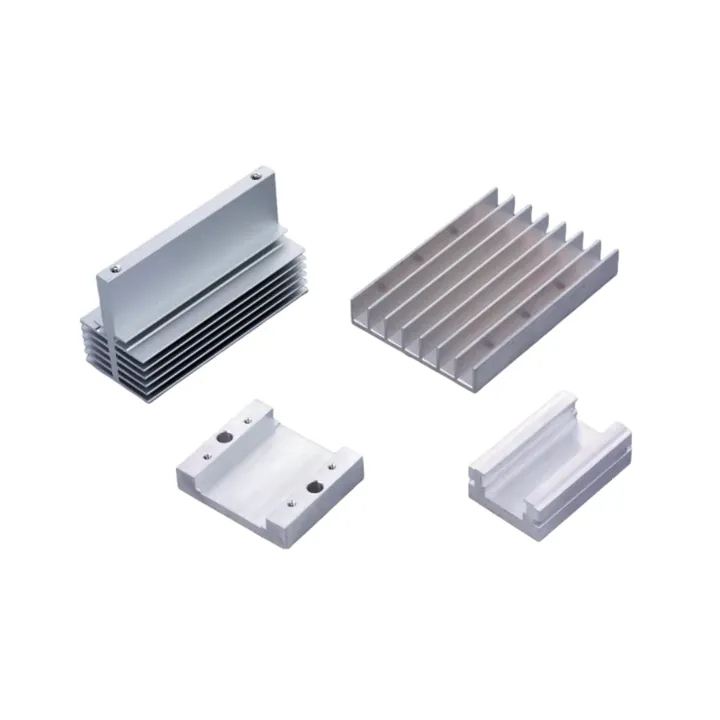

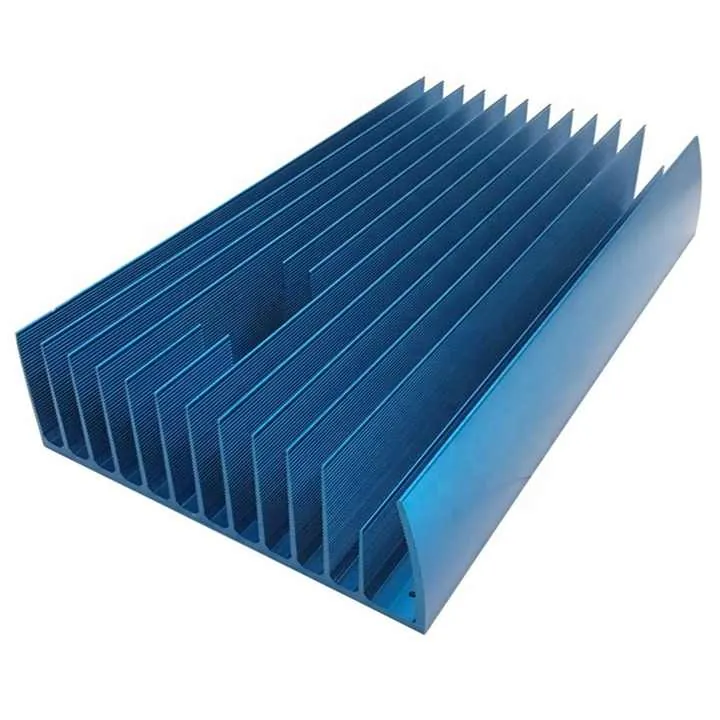

CNC grinding machines can process metals like steel, aluminum, titanium, and non-metals like ceramics and composites, depending on the wheel and setup.

The grinding wheel’s abrasive type and hardness must match the material. The coolant also plays a role in preventing damage or overheating.

Common materials used in CNC grinding

Metals

- Hardened Steel – Frequently used for automotive and tool parts.

- Aluminum – Requires soft abrasives to avoid clogging.

- Titanium – Needs careful cooling to avoid heat damage.

- Brass and Copper – Ground with special wheels to avoid surface smearing.

Non-Metals

- Ceramics – Common in electronics and medical devices.

- Glass – Used in optical parts and lab equipment.

- Composites – Increasingly used in aerospace.

Factors that influence grindability

- Hardness – Harder materials require harder wheels.

- Heat sensitivity – Some materials expand with heat, affecting tolerance.

- Material structure – Brittle materials need a different approach than ductile ones.

Example: Grinding Aluminum vs. Steel

| Feature | Aluminum Grinding | Steel Grinding |

|---|---|---|

| Heat sensitivity | High | Moderate |

| Coolant usage | Heavy | Normal |

| Abrasive type | Softer (e.g., CBN) | Harder (e.g., aluminum oxide) |

| Risk | Wheel clogging | Wheel wear |

By selecting the right grinding wheel and setup, CNC machines can handle almost any material, whether hard, soft, fragile, or heat-sensitive.

What industries use CNC grinding?

CNC grinding sounds technical, but its applications are all around us. From cars to satellites, it plays a hidden but essential role.

Industries that use CNC grinding include automotive, aerospace, medical, electronics, tooling, and precision engineering, where high accuracy and finish are critical.

1. Automotive Industry

Grinding is used to produce camshafts, gears, valve components, and bearings. All of these parts must meet strict tolerances and surface finishes to function properly.

2. Aerospace Industry

CNC grinding shapes high-performance alloys and composites. It’s used for turbine blades, landing gear parts, and other precision components.

3. Medical Field

Devices like surgical tools, implants, and prosthetic joints are often ground to micro-precision. Biocompatible materials require careful grinding without contamination.

4. Tool and Die Making

CNC grinding is essential for manufacturing and re-sharpening cutting tools. Tool performance depends on precision geometry, which grinding can achieve.

5. Electronics

Glass and ceramic components for semiconductors or sensors often need grinding for tight thickness and surface specs.

Key benefits across industries

- High dimensional accuracy

- Consistent repeatability

- Flexible programming

- Suitable for complex or miniaturized parts

Some industries, like defense or robotics, also use CNC grinding for highly specialized parts where manual methods won’t meet the requirements.

Conclusion

CNC grinding is a powerful, precise, and versatile process used across many industries. It’s essential for making high-performance, high-tolerance parts from a variety of materials.