Traditional 3-axis CNC machines can’t always reach every angle. Operators often need multiple setups to finish one part. This wastes time and risks errors.

A 5-axis CNC machine works by moving a cutting tool or part across five different axes at the same time, allowing precise machining of complex geometries in one setup.

Manufacturers use 5-axis machines to cut parts with curves, angles, or tight corners. This machine can rotate and tilt to reach almost any surface, which cuts down on time and improves accuracy.

How does a 5-axis CNC machine move?

When most people see a 5-axis CNC machine, they think it’s just faster. But the real power lies in how it moves and cuts in ways other machines can’t.

A 5-axis CNC machine moves a tool or workpiece along X, Y, and Z axes, and adds two rotational axes—A and B or C—to machine multiple sides without repositioning.

The basic 3 axes are:

- X-axis – left to right

- Y-axis – front to back

- Z-axis – up and down

In a 5-axis machine, two more are added:

- A-axis – rotation around X

- B-axis – rotation around Y

- Or sometimes, C-axis – rotation around Z

This allows the tool to approach the part from virtually any direction. The machine can tilt or rotate the part or the spindle itself.

Common 5-axis configurations

| Type | Description | Use Case Example |

|---|---|---|

| Table-table | Table rotates in A and B axes | Small parts with complex sides |

| Head-table | Spindle head rotates, table tilts | Aerospace parts |

| Head-head | Both axes rotate at the spindle | Tall or large parts |

This flexibility means fewer setups. In traditional machines, operators need to stop and reposition the part to reach new surfaces. 5-axis CNC avoids that.

Why is 5-axis CNC useful for complex parts?

Manufacturers know that complex parts are hard to machine. Sharp angles, deep cavities, and curved surfaces need creative setups—or many machines. That’s inefficient.

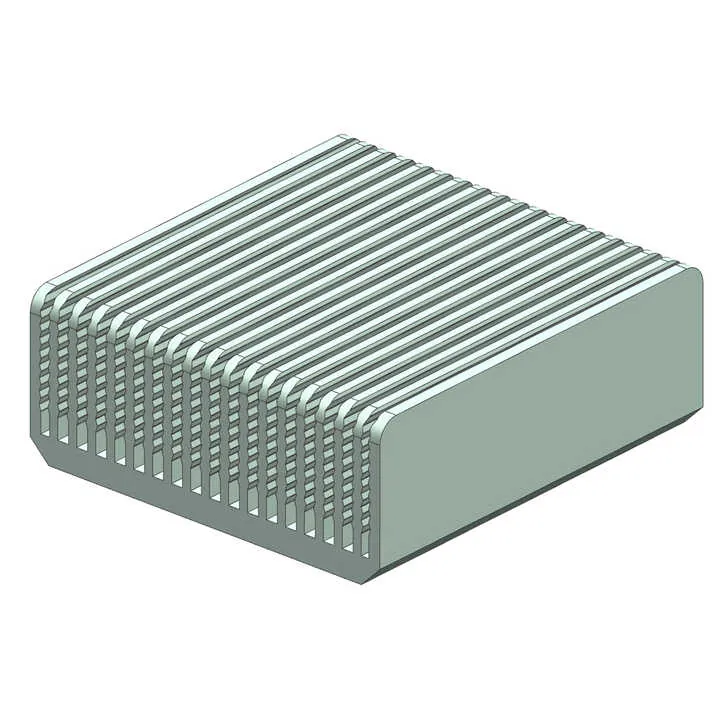

5-axis CNC is useful for complex parts because it can machine multiple angles and surfaces in one operation, improving accuracy and cutting down setup time.

This ability is essential for making parts with features like:

- Rounded edges

- Steep angles

- Undercuts

- Deep pockets

Benefits for complex geometry

- Precision – Each movement is controlled by software with tight tolerances.

- Reduced setups – The machine adjusts angles automatically.

- Surface quality – Smooth finishes due to optimal tool orientation.

- Tool life – Less vibration and better angle reduce tool wear.

Example: Aerospace Turbine Blade

This part has curved surfaces and needs tight tolerances. In 3-axis machining, it might take 6 setups. A 5-axis machine can finish it in one setup.

Critical factors for success

| Factor | Impact on Complex Parts |

|---|---|

| Tool orientation | Better access to deep features |

| Collision avoidance | Prevents crashes in tight spaces |

| CAD/CAM software | Generates optimized tool paths |

| Machine rigidity | Improves quality at high speeds |

With 5-axis CNC, manufacturers save hours of work and reduce human error, especially when handling high-value parts.

Which industries need 5-axis CNC machines?

Not every company needs 5-axis CNC. But for some industries, it’s no longer optional—it’s essential.

Industries that need 5-axis CNC machines include aerospace, medical, automotive, mold making, and precision engineering, where accuracy and part complexity are critical.

1. Aerospace

Aircraft parts are often complex and large. Turbine blades, brackets, and engine housings need precise curves and multiple angles. 5-axis machining makes that possible.

2. Medical Devices

Implants like hip joints or dental components need complex 3D shapes and must meet tight tolerances. A small error can affect patient safety.

3. Automotive

Some performance parts, especially in motorsports or EVs, need compact designs and fine detailing. 5-axis CNC helps produce these parts faster.

4. Mold and Die Industry

Molds for plastics, injection molding, or casting often have complex shapes. 5-axis CNC machines reduce lead time by machining these shapes in fewer steps.

5. Energy Sector

Parts used in wind turbines, nuclear plants, or oil rigs must handle stress and fit precisely. The accuracy of 5-axis machines ensures this reliability.

Industry comparison

| Industry | Common Parts Produced | Key Benefit of 5-Axis CNC |

|---|---|---|

| Aerospace | Blades, casings, brackets | Accuracy for complex geometry |

| Medical | Implants, surgical tools | High precision, low error |

| Automotive | Engine parts, suspension pieces | Faster cycles, fewer setups |

| Mold making | Injection molds, cast tools | Multi-angle tool paths |

| Energy | Shafts, housings, gearboxes | Consistent finish and fit |

Any industry producing high-value, low-tolerance parts can benefit from the added flexibility and speed of 5-axis machining.

Where are 5-axis CNC machines used?

People often assume 5-axis machines are only in high-tech labs. But they’re showing up in many manufacturing shops, across regions and industries.

5-axis CNC machines are used in high-precision machine shops, OEM manufacturing plants, R&D facilities, and custom prototyping centers across the globe.

Common settings

Machine Shops

Medium to large shops invest in 5-axis to take on advanced projects. These machines help win contracts from industries that demand tight tolerances.

OEM Factories

Companies like Airbus, GE, or Siemens use 5-axis CNCs in their production lines. They use it for serial production of key components.

Prototyping Labs

Startups and R&D centers use 5-axis CNCs to create one-off parts quickly. It speeds up development and testing.

Educational Institutions

Engineering universities use them for training. This helps students understand real-world manufacturing constraints.

Regional trends

| Region | Adoption Level | Common Users |

|---|---|---|

| North America | High | Aerospace and medical sectors |

| Europe | Very High | Automotive, defense, industrial |

| Asia-Pacific | Growing fast | Electronics and consumer goods |

| Middle East | Moderate | Energy sector and construction |

5-axis machines are no longer rare. As prices drop and software improves, more factories—large or small—are adopting this technology.

Conclusion

A 5-axis CNC machine works by moving along three linear axes and two rotational axes, allowing precise machining from all angles. It’s a must-have for industries that demand speed, accuracy, and the ability to produce complex parts in fewer setups.