Aluminum shows up in more products than most people realize. But not all aluminum parts are made the same way. Some are cast. Others are precisely machined.

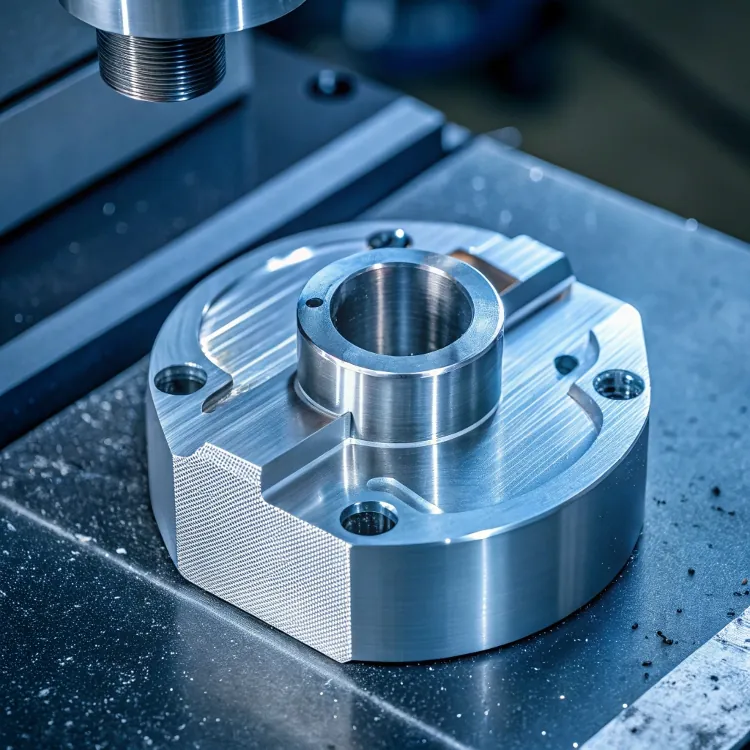

CNC aluminum refers to aluminum parts made by computer-controlled cutting tools, known as CNC machines, that shape the metal with high accuracy and detail.

If you're working on a new product or mechanical part, chances are you'll deal with CNC aluminum at some point. Let's break down what makes it unique.

Definition and Key Properties of CNC Machined Aluminum?

People often confuse the term CNC aluminum with just any aluminum part. But it has very specific characteristics.

CNC machined aluminum is aluminum that has been precisely shaped using a CNC machine, offering tight tolerances, smooth finishes, and consistent dimensions.

CNC machining is subtractive. The machine removes material from a solid aluminum block using tools controlled by a digital file. This method allows for:

- High repeatability

- Complex geometries

- Very smooth surfaces

- Tight tolerances (often ±0.01 mm)

Key Properties

| Property | Description |

|---|---|

| Strength-to-weight ratio | Lightweight yet strong |

| Corrosion resistance | Especially with anodizing |

| Thermal conductivity | Helps in heat dissipation |

| Machinability | Cuts cleanly with low tool wear |

| Surface finish | Polished, matte, or anodized available |

Most of the time, we use 6061 or 6063 alloys in CNC machining. These are popular because they’re easy to machine, durable, and look great after anodizing.

Differences Between Cast and CNC Machined Aluminum?

Not all aluminum parts are created equally. The method of making them changes their strength, surface quality, and cost.

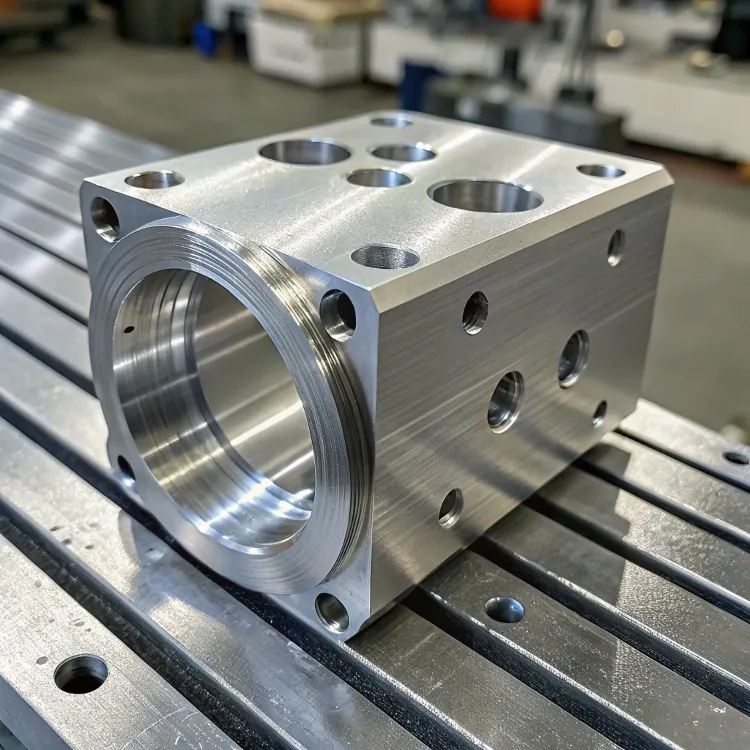

CNC machined aluminum starts from a solid billet and is milled into shape, while cast aluminum is formed by pouring molten metal into a mold.

Here's how they compare:

CNC Machined vs Cast Aluminum

| Feature | CNC Machined Aluminum | Cast Aluminum |

|---|---|---|

| Production Volume | Low to medium | High |

| Tolerance Accuracy | High (±0.01 mm) | Moderate |

| Surface Finish | Smooth, customizable | Rougher, may need machining |

| Structural Integrity | Stronger, less porous | Weaker, prone to porosity |

| Setup Cost | Low (no molds needed) | High (mold design and tooling) |

| Material Options | Wider alloy choices | Limited by casting process |

When I support clients with low-volume or high-precision work, I always recommend CNC over casting. It saves time and avoids the upfront cost of molds.

Industries That Rely on CNC Aluminum Parts?

It’s surprising how many industries need CNC aluminum parts. From tiny brackets to structural frames, it shows up everywhere.

Industries like aerospace, electronics, automotive, robotics, and medical devices all depend on CNC aluminum parts for strength, weight, and accuracy.

I've worked with clients across these sectors. What they all have in common is a need for reliable parts with predictable quality. CNC aluminum offers just that.

Common Use Cases

| Industry | CNC Aluminum Applications |

|---|---|

| Aerospace | Structural brackets, housings |

| Automotive | Engine parts, mounts, connectors |

| Consumer Electronics | Device frames, thermal enclosures |

| Medical Devices | Structural supports, custom jigs |

| Industrial Equipment | Chassis parts, automation brackets |

| Robotics | Arms, joints, sensor housings |

These parts are often complex in shape and require tight tolerances, which casting or stamping can't guarantee. That's why CNC becomes the go-to choice.

Why CNC Aluminum Is Preferred for Prototyping and Custom Parts?

Speed and flexibility matter most in early product development. CNC machining makes quick changes easy.

CNC aluminum is preferred for prototyping because it allows fast iteration, high accuracy, and good surface finishes without tooling costs.

When I work with startups or design houses, they're always pushing deadlines. They often need to test form, fit, and function—sometimes within days. CNC machining gives them this speed without compromise.

Why CNC Aluminum Wins in Prototyping

- No mold cost: Parts are made directly from CAD files.

- Quick turnaround: We can deliver samples in as little as 3 days.

- Customizable: Easy to change design between runs.

- High quality: Parts are ready for testing or even final use.

Real-World Example

One of our American clients needed a custom aluminum housing for a new sensor. They had a tight launch date. We delivered 10 prototypes in 4 days, including black anodizing. No molds, no delays—just fast and clean parts.

Conclusion

CNC aluminum stands out for its precision, strength, and versatility. Whether it's for prototyping or final production, it's a smart choice across many industries.