Products Details

Our Manufacturing Base

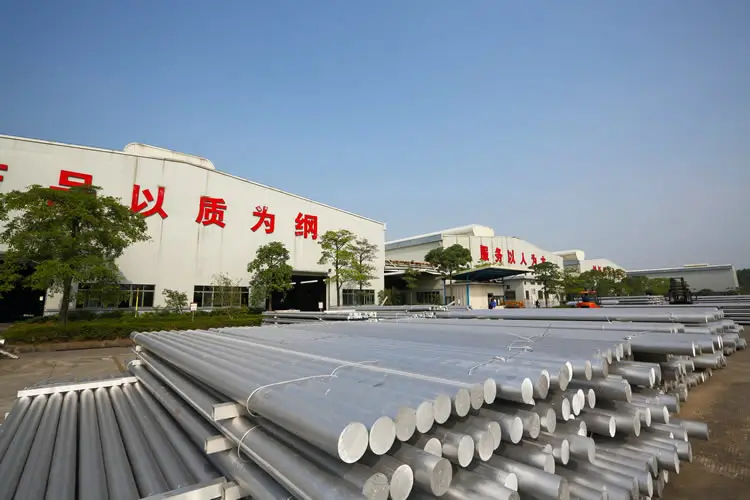

Factory Panorama

Aluminum Bar Manufacturing Workshop

Mold Storage Warehouse

43 Aluminum Extrusion Lines (500–5500 Tons)

Powder Coating Workshop

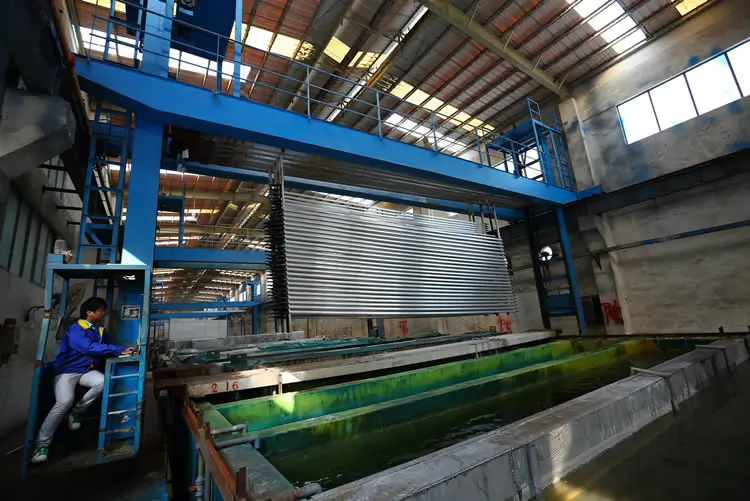

Anodizing Workshop

Deep Processing Workshop

CNC Precision Machining Workshop

Finished Product & Export Warehouse

FAQ

1. What is friction stir welding?

Friction stir welding is a solid-state joining process effective for aluminum structures.

2. Why choose aluminum for structural parts?

Aluminum offers a lightweight and strong solution for structural components.

3. Can friction stir welding be used on all aluminum grades?

Yes, it is suitable for a wide range of aluminum grades used in structural parts.

4. What are the advantages of friction stir welded aluminum?

It provides enhanced strength, reduced weight, and increased corrosion resistance.

5. Is friction stir welded aluminum suitable for automotive applications?

Yes, it is ideal for automotive parts due to its lightweight and high strength.

6. How does friction stir welding impact environmental sustainability?

The process is eco-friendly as it does not require filler materials or generate harmful emissions.

7. Can this process be automated?

Yes, friction stir welding can be integrated into automated manufacturing systems for consistent quality.