When I first got into performance engines, I kept hearing about "CNC heads." I wondered: are all aluminum heads cast, or are they fully machined?

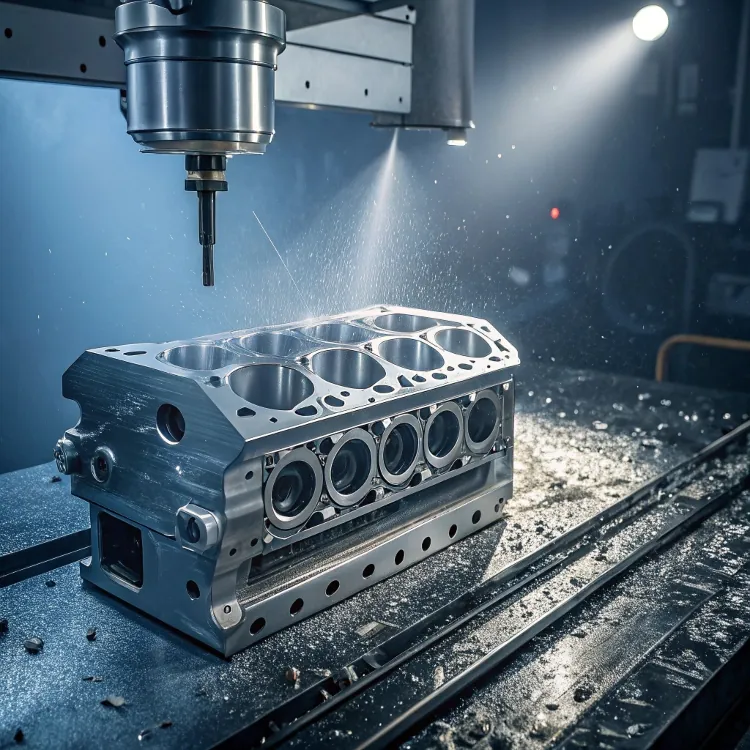

Most aluminum heads start as castings, but high-performance versions are CNC-machined for better precision and airflow.

I learned that casting creates the basic shape, but CNC machining refines critical areas. In racing or custom builds, heads often go through full CNC porting and surfacing for best results.

What is the difference between cast and CNC-machined aluminum heads?

At first glance, cast and CNC heads may look the same. But the way they're made—and how they perform—is very different.

Cast heads are shaped in molds, while CNC-machined heads are cut with precision tools to improve airflow and accuracy.

Casting is great for mass production. Molten aluminum is poured into molds, cooled, and machined only where needed. CNC machining, by contrast, removes metal to shape exact curves and chambers.

Key Differences Between Cast and CNC-Machined Heads

| Feature | Cast Aluminum Heads1 | CNC-Machined Aluminum Heads |

|---|---|---|

| Production Method | Mold casting | CNC tool cutting |

| Surface Finish | Rougher | Smooth, consistent |

| Airflow Control | Limited by mold shape | Tuned via precise port shaping |

| Cost | Lower | Higher due to machining time |

| Tolerances | Moderate | Very tight |

When I upgrade to CNC heads, I see smoother ports, symmetrical combustion chambers, and cleaner valve seats—all crucial for performance engines.

Do performance engines use CNC aluminum heads?

Many people ask if CNC heads are just for show. From my experience and what I’ve seen in pro shops—the answer is clear.

Yes, performance engines often use CNC aluminum heads to maximize airflow, compression accuracy, and combustion efficiency.

In drag racing, drifting, and even high-end street builds, CNC heads are standard. They’re not just for pros—many aftermarket brands offer them as plug-and-play options.

Why? Because they unlock power. CNC porting2 matches intake and exhaust precisely. Chamber sizes are controlled. Valve placement is accurate. This adds horsepower and consistency.

Advantages of CNC Heads in Performance Applications

- Equalized flow across cylinders

- Higher combustion efficiency

- Reduced risk of knock from chamber variation

- Stronger structure due to uniform machining

I’ve used both types in builds. Cast heads work well for basic upgrades. But CNC heads give me more control over engine behavior, especially at higher RPMs.

Are CNC router aluminum heads more precise than cast ones?

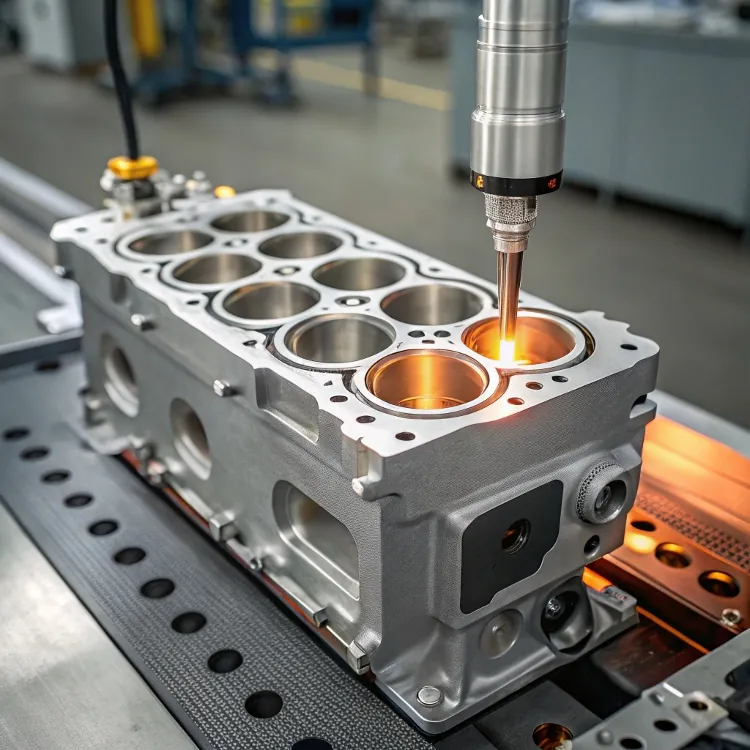

Precision matters in engines. Even small shape differences affect combustion. That’s why CNC heads outperform cast-only versions.

Yes, CNC router aluminum heads are more precise than cast heads, especially in port shapes, valve angles, and chamber volume.

Casting can’t guarantee uniformity. Some ports end up slightly bigger or smaller. With CNC, every head comes out exactly the same. That consistency improves balance across cylinders.

For me, the most noticeable gain is throttle response3. With matched ports, the engine breathes evenly. Also, tuning gets easier since airflow isn’t unpredictable from one cylinder to another.

How CNC Machining Improves Precision

- Port shape matches CAD models

- Chamber volumes are within 0.5cc across all cylinders

- Valve seats are cut at perfect angles

- Surface finish helps fuel atomization

Whether I build a turbo engine or a naturally aspirated one, CNC heads help me dial in power, torque, and reliability.

How to identify a CNC-machined aluminum cylinder head?

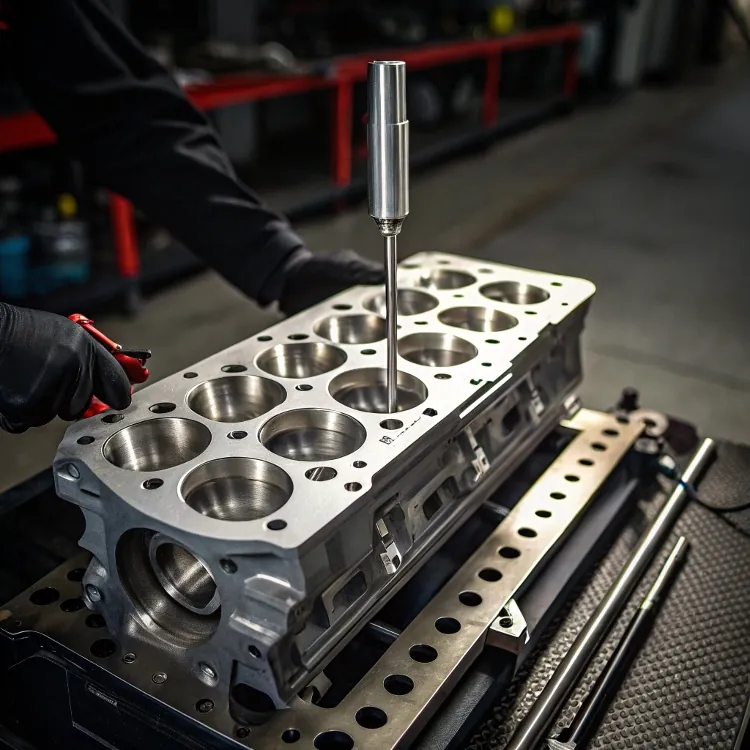

Some heads are labeled CNC, but how can I tell if they really are? I look for clear signs during inspection.

You can spot CNC-machined heads by their smooth port walls, consistent tool patterns4, and symmetrical chamber shapes.

Most CNC ports have visible tool marks—thin, even lines from end mills. These are different from the rough sand-cast texture inside unmachined ports.

Also, CNC heads usually have exact symmetry between cylinders. I measure port diameters and chamber volumes to confirm. Cast-only heads often show slight shape irregularities.

How to Check if a Head is CNC-Machined

| Indicator | What to Look For |

|---|---|

| Port Surface Finish | Smooth, visible machine tool marks |

| Chamber Consistency | Chambers are identical in shape and size |

| Branding or Engraving | “CNC Ported” or model ID from suppliers |

| Flow Bench Data | Consistent flow across all runners |

| Port Entry Geometry | Radiused, precision-shaped intake paths |

When buying used, I always inspect ports with a flashlight. If the surface is smooth and symmetrical, it's likely CNC. For new heads, most brands clearly label their porting method.

Conclusion

CNC aluminum heads offer better precision, flow, and performance than cast-only heads. They're the top choice in serious engine builds and easy to identify with the right checks.

-

Learn about the benefits of cast aluminum heads, especially in mass production and cost-effectiveness. ↩

-

Learn about CNC porting and its role in maximizing engine performance and efficiency. ↩

-

Discover how CNC machined heads enhance throttle response and overall engine performance for better driving experience. ↩

-

Consistent tool patterns indicate precision in machining, which is essential for optimal engine performance. ↩