Many people assume all metals rust the same way. But have you ever seen a rusty aluminum part? Probably not—and there’s a scientific reason behind that.

No, aluminum does not rust like iron. Instead, it forms a protective oxide layer that shields it from further corrosion.

Aluminum behaves differently from iron due to its unique surface chemistry. This article will explain how aluminum resists rust, what makes it corrode under certain conditions, and why that matters for product designers and engineers.

Why Doesn’t Aluminum Rust Like Iron?

Rust ruins iron quickly, but aluminum stays shiny and strong for years. Why the difference?

Aluminum doesn’t rust because rust is specific to iron. Instead, aluminum forms aluminum oxide, a stable, non-flaky layer that protects it from further corrosion.

Aluminum reacts with oxygen in the air almost instantly. But instead of forming a flaky red rust like iron, it builds a super-thin but strong layer of aluminum oxide. This happens naturally, even at room temperature.

What Is Rust, and What Is Oxidation?

Let’s break this down.

| Term | Material | Result | Appearance |

|---|---|---|---|

| Rust | Iron/Steel | Iron oxide (Fe₂O₃) | Reddish, flaky |

| Oxidation | Aluminum | Aluminum oxide (Al₂O₃) | Invisible or dull gray |

Iron rust flakes off, exposing more metal to corrosion. That’s why rusty parts keep getting worse. Aluminum oxide, however, clings tightly to the surface, forming a barrier that stops more air and moisture from reaching the metal.

This is why you often see decades-old aluminum window frames or aircraft parts still looking good. The oxide layer forms quickly and protects deeply.

Real-World Example

In our factory, we once supplied CNC-machined aluminum parts to a customer designing outdoor sensors. He was worried about rust, just like with steel enclosures. We explained how aluminum forms this oxide layer, and after a few real-world tests, his team switched entirely to anodized aluminum.

What Causes Aluminum Corrosion?

Aluminum doesn’t rust, but it can still corrode. Under what conditions does that happen?

Aluminum corrodes when its protective oxide layer is damaged or exposed to harsh chemicals like chlorides or acidic environments.

The natural oxide layer is self-healing and durable, but not invincible. When aluminum is scratched, exposed to saltwater, or placed in environments with low pH (acids) or high pH (strong bases), it can corrode.

Main Triggers of Aluminum Corrosion

| Cause | Description | Examples |

|---|---|---|

| Salt (chlorides) | Attacks oxide layer | Marine environments, road salt |

| Acids or bases | Breaks down oxide | Industrial cleaning agents |

| Galvanic corrosion | Happens when aluminum touches another metal | Mixed-metal assemblies |

In coastal cities, for example, salt in the air can lead to pitting corrosion in aluminum parts. We’ve seen customers working on marine robotics request anodizing and sealing to protect underwater aluminum enclosures from this exact issue.

Surface Finishes Matter

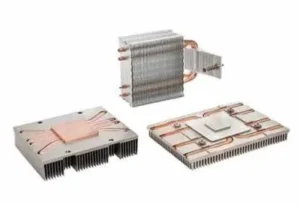

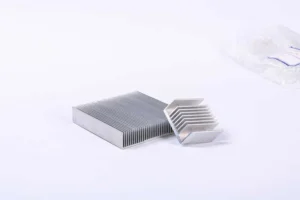

Surface treatment changes the game. At Sinoextrud, we often recommend anodizing for better corrosion resistance. Anodizing thickens the natural oxide layer, sealing it for even more protection. If the part needs even more durability, we add sealing steps after anodizing.

How Does the Oxide Layer Protect Aluminum?

The oxide layer might be invisible, but it does a powerful job. What makes it so effective?

The oxide layer stops oxygen and moisture from reaching the bare metal, preventing further corrosion. It’s thin, tough, and self-repairing.

When aluminum is exposed to air, oxygen molecules immediately react with the surface to create aluminum oxide. This layer is only a few nanometers thick but extremely dense. It acts like a shield. Even if you scratch it, it quickly reforms.

Key Properties of the Oxide Layer

- Thin but dense: Only a few nanometers thick but blocks oxygen and moisture

- Adheres tightly: Unlike iron rust, it doesn’t flake off

- Self-repairing: Reforms immediately if damaged

- Colorless or gray: Often not visible to the naked eye

How We Enhance the Layer

At Sinoextrud, we often enhance this natural shield by anodizing the part. Anodizing grows the oxide layer to 10–25 microns or more, depending on the application. It can be dyed for aesthetics or sealed for extra durability. Anodized layers are much more resistant to wear, salt, and chemicals.

Customers in industries like consumer electronics, medical devices, and automotive frequently ask us to anodize CNC-milled parts not just for appearance—but for corrosion protection too.

When Does Aluminum Show Corrosion?

If aluminum is so resistant, when can we expect problems?

Aluminum shows corrosion when exposed to salty environments, harsh chemicals, or when combined with dissimilar metals without insulation.

In most indoor or dry environments, aluminum stays clean and corrosion-free. But we’ve seen issues in these cases:

1. Saltwater Exposure

Salt attacks the oxide layer. Boats, marine structures, or road vehicles often face this. That’s why marine-grade aluminum alloys like 5052 or 6061-T6 with anodizing are common.

2. Galvanic Corrosion

If aluminum is connected to copper, steel, or stainless steel without insulation, electrons flow between them. This damages the aluminum. It happens a lot in mixed-metal assemblies.

3. Acidic or Basic Exposure

Cleaners or chemicals with extreme pH values can strip the oxide layer, leaving the aluminum exposed. This causes white, chalky corrosion or even pitting.

4. Trapped Moisture

In tight gaps where moisture gets in but can't dry, corrosion can form slowly over time, especially near welds or joints.

Best Practices We Recommend

- Use proper surface treatment: Anodizing, painting, or powder coating.

- Avoid dissimilar metals: Use plastic washers or coatings if metals must contact.

- Rinse after salt exposure: For outdoor products, rinsing off salt helps preserve the finish.

- Choose the right alloy: Some, like 6061 and 5052, are more corrosion-resistant than others.

Here's a helpful table comparing corrosion resistance across common aluminum alloys:

| Alloy | Corrosion Resistance | Notes |

|---|---|---|

| 6061 | Good | Widely used, strong, anodizable |

| 5052 | Excellent | Marine-grade, great for saltwater |

| 7075 | Moderate | Strong but prone to corrosion, needs coating |

| 2024 | Low | High strength but poor corrosion resistance |

Conclusion

Aluminum doesn’t rust like iron, thanks to its protective oxide layer. But under the wrong conditions, corrosion can still happen—so it’s key to pick the right alloy and surface treatment.