Renting a CNC machine can sound like a good idea — but how much will it really cost? The answer depends a lot on machine type, rental duration, services included, and local market.

Typical CNC rental rates vary widely — from modest hourly rates for simple jobs to hundreds of dollars per hour for high-end machines. Many operators pay roughly $50–$500 per hour depending on the machine and services.

If you’re considering renting a CNC machine for your project, this article breaks down the costs, when it makes sense to rent, which machines are most expensive, and where to find rental services.

How do rental prices vary?

Rental prices for CNC machines vary because there are many factors: machine type, complexity of the job, rental duration, included services (operator, maintenance, tooling), and even material being machined.

For simpler CNC machines (basic mills or routers), hourly rental or machining-service rates might start low. For high-spec machines (multi-axis milling or heavy machining), hourly prices typically increase significantly.

What influences price

- Machine type and complexity – A simple 3-axis router or small CNC mill costs much less than a 5-axis mill-turn center.

- Material and job difficulty – Tough materials, tight tolerances, or complex 3D profiles increase cost.

- Rental duration & setup – Short-term rentals cost more per hour; long-term contracts usually get discounted rates.

- Included services – If the rental includes an operator, tooling, or maintenance, expect to pay more.

- Location and market – Rates vary across regions and countries.

Example Rate Ranges

| Service Type / Machine | Typical Hourly Rate |

|---|---|

| Basic 3-axis CNC milling | $50–$80/hour |

| 4-axis or 5-axis vertical center | $100–$200/hour |

| Mill-turn or large-format machine | $200–$500+/hour |

Some UK-based services report CNC machining services starting from £25 to over £120 per hour. In the US and Europe, rates may be higher if setup, tooling, and CAD support are included.

Always ask for a detailed quote based on part specs and time estimates before renting.

Why rent instead of buying?

Buying a CNC machine is a major investment. Not all businesses are ready to commit that much capital — especially if production needs are short-term or uncertain.

Renting a CNC machine avoids upfront costs, reduces long-term risk, and offers flexibility for prototypes, trials, or short production runs.

Benefits of Renting

- Lower upfront cost – No large capital purchase required.

- Short-term flexibility – Ideal for short runs, trial projects, or seasonal spikes.

- No maintenance headaches – Service and upkeep are often included.

- Try before you buy – Renting lets you test a machine type before buying one.

- Quick capacity boost – Add extra output without permanent investment.

For small workshops, startup manufacturers, or custom parts makers, renting a CNC machine provides just the right capacity without long-term obligations.

Which CNC models cost most?

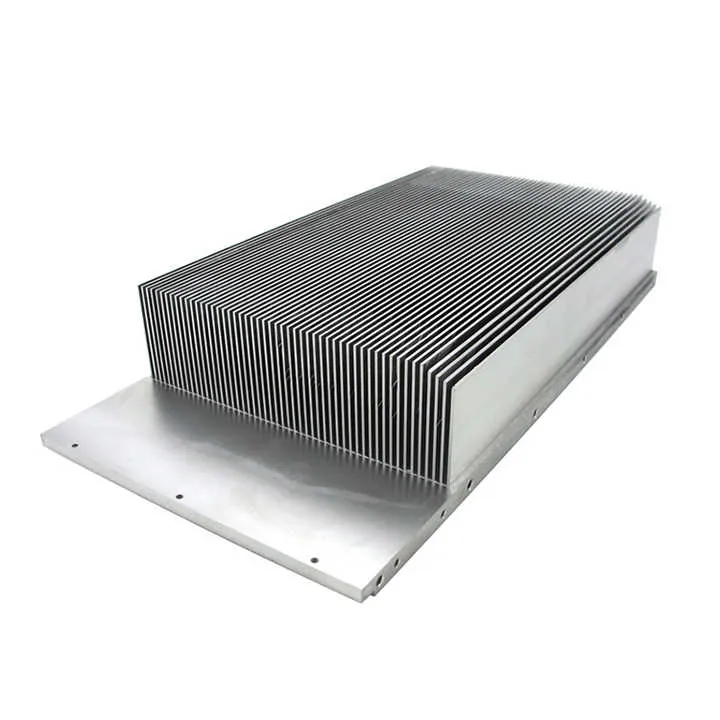

Not all CNC machines are created equal. Some models offer much more power, precision, and functionality — and their rental rates reflect that.

High-end 5-axis machining centers, mill-turn machines, and large heavy-duty machines cost the most to rent due to their complexity, capability, and demand.

Features That Increase Rental Cost

- Multi-axis capabilities – 5-axis machines can do complex geometry and fewer setups.

- Heavy-duty structure – Machines built to cut steel or titanium cost more than those built for plastics or aluminum.

- High spindle power – More kW = more cutting power = more cost.

- Advanced control systems – Precision control and automation raise both capability and rental rates.

- ATC and automation – Automatic Tool Changers and robotic arms save time, but cost more.

These high-spec machines are essential for aerospace, mold & die, or high-precision applications — but expect the rental cost to reflect their capabilities.

Where to find CNC rental services?

If you’re ready to rent, where do you start? The good news is that several platforms and services now support CNC machine rental or on-demand machining.

CNC machines can be rented directly from equipment rental companies, machining service shops, or through online manufacturing platforms that offer part-making as a service.

Where to Look

- CNC Equipment Rental Firms – In Europe and North America, some companies specialize in renting CNCs for weeks or months.

- Job Shops / CNC Contractors – Instead of renting, you can outsource machining to a job shop. They operate the machine and deliver the parts.

- Online Manufacturing Services – Sites like Hubs or Xometry allow you to upload CAD files and get CNC parts made without owning or renting a machine.

- Local Makerspaces or Fab Labs – Some allow members to rent CNC router or mill time on a pay-per-hour basis.

Before renting, make sure to clarify:

- Rental duration (hourly, daily, monthly)

- Services included (operator, CAD/CAM help, tool changes)

- Machine specs and axis count

- What materials can be cut

- Insurance or damage clauses

A good service provider will give you a full quote and explain what’s included.

Conclusion

There is no one-size-fits-all answer to CNC machine rental costs. Simple machines may cost $50/hour; advanced 5-axis systems can go beyond $500/hour. Renting is smart for prototyping, short runs, or temporary needs. The key is choosing the right machine, understanding what’s included, and finding a reliable service provider to match your part requirements and timeline.