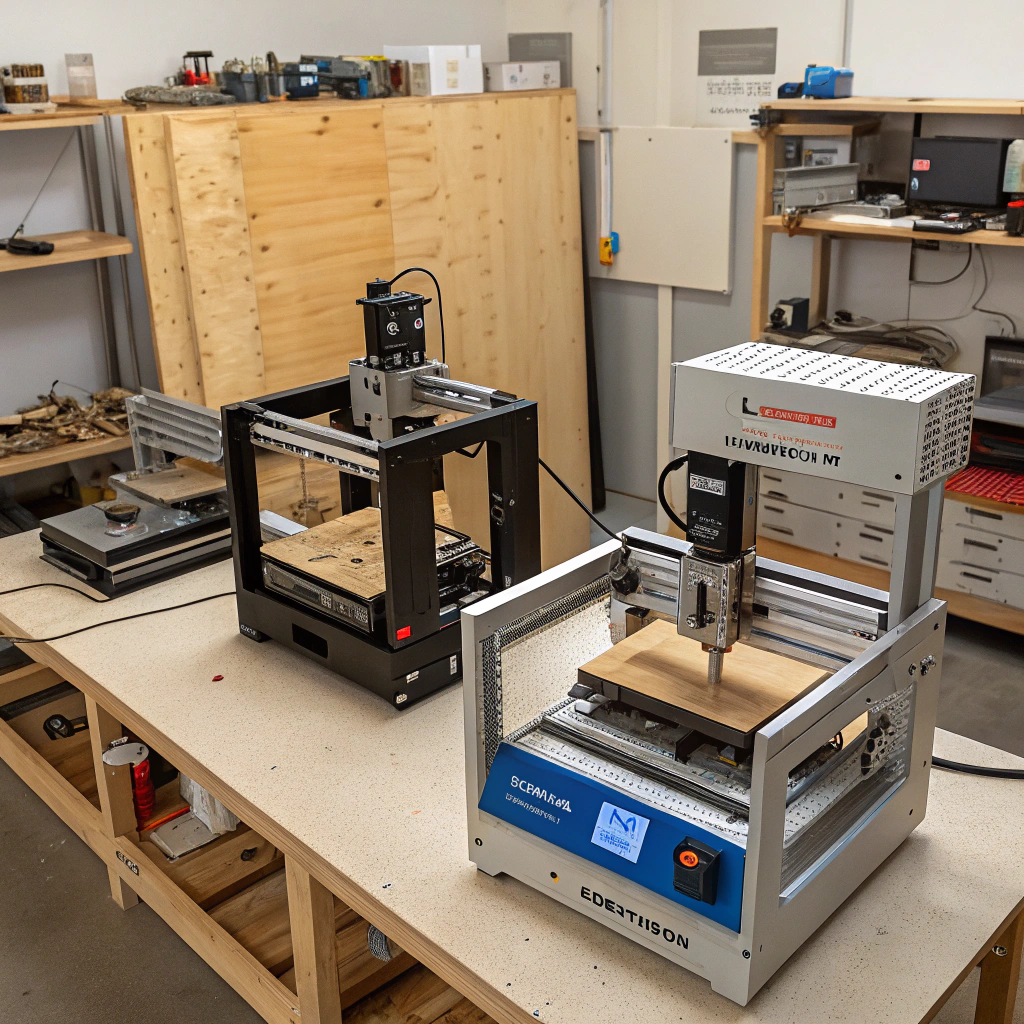

Woodworkers often hesitate to invest in CNC machines, fearing high prices or unclear value. But CNC tools today range from hobby-friendly kits to industrial routers with powerful capabilities.

A CNC machine for woodworking typically costs between $150 and $30,000+, depending on its size, features, build quality, and intended use.

Understanding price ranges helps you choose a machine that matches your project needs and budget. Let’s explore how these costs break down.

What is the price range for a CNC machine for woodworking?

Many people assume CNC tools are only for factories. But affordable models have made this technology accessible to hobbyists and small workshops.

CNC woodworking machines range from around $150 for small desktop kits to over $30,000 for large, industrial-grade routers.

Here’s a breakdown of the main categories and typical prices:

CNC Machine Price Categories

| Category | Price Range | Best For |

|---|---|---|

| Desktop / Hobby CNCs | $150 – $2,000 | Engraving, signs, small projects |

| Small Workshop CNCs | $2,000 – $10,000 | Furniture, cabinetry, medium output |

| Professional CNC Routers | $10,000 – $30,000 | Doors, panels, full-size production |

| Industrial Wood CNCs | $30,000+ | High-volume, heavy-duty processing |

Some machines, like the Genmitsu 4040-PRO MAX, start under $1,000 and are popular with home users. Others, like the Laguna Swift 4x8, cost around $20,000 and are used in serious production shops.

Low-cost doesn't always mean low-quality—many small routers offer good performance for their price, especially for softwood or MDF carving.

How do features and size affect the cost of a CNC machine for wood?

Woodworkers often ask why two machines with similar appearances cost thousands apart. The answer lies in features, size, and mechanical strength.

Larger working areas, stronger frames, better motors, and more automation features increase the price of CNC machines for wood.

Key Price Drivers

1. Working Area Size

- Smaller (300mm x 300mm) – for signs or small parts

- Mid-size (600mm x 900mm) – for cabinet doors, panels

- Full-size (4x8 ft) – for furniture, sheet processing

Larger machines require bigger frames and stronger motors, adding cost.

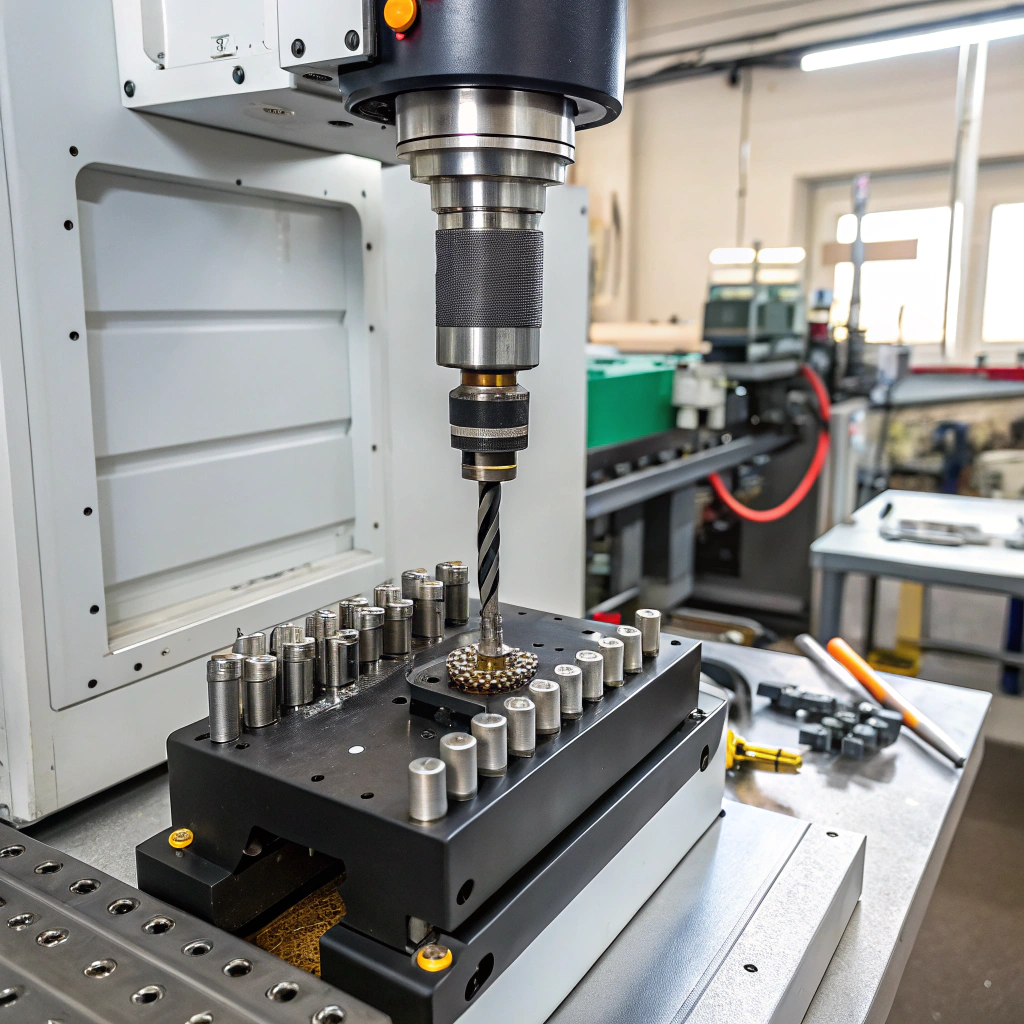

2. Spindle Power

- Entry-level: 300W – 800W

- Mid-tier: 1.5kW – 2.2kW

- Industrial: 3kW and up

Power affects cutting depth, speed, and material capability.

3. Construction Material

- Cheap machines use aluminum frames or plastics

- Premium machines use steel or cast aluminum for stability

Heavier builds reduce vibration and improve accuracy.

4. Automation Features

| Feature | Description | Cost Impact |

|---|---|---|

| Automatic Tool Changer | Changes bits automatically | High |

| Vacuum Table | Holds wood in place without clamps | Medium |

| Dust Collection | Removes chips and dust during cutting | Medium |

| Rotary Axis | Enables 4th-axis wood turning | Medium |

Features like these make production easier, faster, and more consistent—but raise costs.

5. Controller and Software

High-end machines often include:

- Touchscreen controllers

- Industrial-grade servo systems

- Professional CAM software licenses

Budget machines may require separate software or use open-source options.

The more powerful and automated the system, the more expensive it becomes—but also more productive.

Which brands offer affordable CNC machines for wood?

Choosing a trusted brand ensures better support, user communities, and upgrade paths. Several manufacturers provide reliable machines at reasonable prices.

Popular affordable brands for wood CNC machines include Genmitsu, TwoTrees, Next Wave CNC, StyleCNC, and Forsun.

Notable Models and Prices

| Brand & Model | Approx. Price | Best Use |

|---|---|---|

| Genmitsu 4040-PRO MAX | ~$949 | Hobby carving, small parts |

| TwoTrees TTC6050 | ~$1,599 | Mid-size workshop projects |

| Next Wave Shark SD110 | ~$1,499 | Detailed sign making |

| StyleCNC STM1325 | ~$5,480 | Furniture, cabinetry |

| Forsun FS1325A | ~$2,500 | Full-size sheet cutting |

| Laguna Swift 4x8 | ~$19,995 | Industrial production |

These machines vary in features, size, and precision. Some are kits for assembly, while others arrive pre-built and ready to run.

Most brands offer online support, replacement parts, and upgrade options. Check for reviews, customer service, and software compatibility before buying.

What factors influence the cost of CNC machines for wood?

When planning your CNC purchase, cost depends on more than just the sticker price. Long-term performance and upgrades also matter.

Main factors affecting CNC wood machine cost include size, spindle power, build quality, automation, brand, and included software.

Breakdown of Cost Factors

A. Table Size

- Larger machines handle sheet goods like plywood or MDF

- Increases frame size, motor power, and weight

B. Spindle Type

- Air-cooled spindles are cheaper but louder

- Water-cooled spindles offer better temperature control and longer lifespan

C. Motion System

- Cheaper models use belts (lower cost but less accuracy)

- More expensive machines use ball screws or linear rails for better precision

D. Electronics & Controller

- Basic machines use GRBL or Arduino-based boards

- Advanced models use Mach3, DSP, or industrial PLCs

E. Brand Reputation

- Trusted brands may cost more but offer better support, warranty, and resale value

F. Delivery and Installation

- Large CNC routers may require freight shipping

- Industrial machines often need on-site setup or training

G. Software and License

Some machines include CAM software, others don’t. Paid options like Vectric VCarve, Aspire, or Fusion 360 may be necessary.

Cost vs. Value Table

| Factor | Budget Machine | Premium Machine |

|---|---|---|

| Size | Small (under 2ft) | Large (4x8 ft) |

| Spindle | Low power, air-cooled | High power, water-cooled |

| Frame | Light aluminum | Steel or heavy-duty alloy |

| Controller | Basic (GRBL) | Industrial (DSP, Mach3) |

| Automation | Manual tool change | Full ATC, vacuum table |

| Price Range | $150 – $2,000 | $10,000 – $30,000+ |

More features and stronger builds offer long-term reliability, but only if you need that performance level.

Conclusion

CNC machines for woodworking come in all sizes and prices. Whether you're a hobbyist, small shop, or industrial producer, there's a machine that fits your needs and budget. The key is understanding what features truly matter for your projects—so your investment turns into productivity, not regret.