Many people confuse 3D printers with CNC machines. They both use computer control, and they both shape materials. But they work in opposite ways.

A 3D printer is not a CNC machine. CNC is subtractive — it removes material. 3D printing is additive — it builds layer by layer.

They are both part of digital manufacturing. But they serve different roles. Let’s break down how they compare and when to use each.

How does 3D printing differ from CNC?

At first glance, both 3D printing and CNC machining follow digital instructions. Both use G-code to move tools or nozzles. But what they do with the material is completely different.

3D printing adds material to build an object, while CNC machining removes material to shape an object.

Material movement: opposite directions

3D printing works by laying down material layer by layer, starting from nothing. CNC starts with a solid block and cuts away parts until the shape is revealed.

Main differences in process

| Feature | 3D Printing | CNC Machining |

|---|---|---|

| Method | Additive (builds up) | Subtractive (cuts away) |

| Waste | Minimal | Often significant |

| Speed (per part) | Slower for large parts | Faster for single parts |

| Accuracy | Lower (especially FDM printers) | High precision |

| Strength | Layer bonding can be weak | Solid and consistent |

| Material flexibility | Plastics, resin, some metals | Metals, plastics, composites |

Applications and limitations

3D printing is better for making prototypes, small parts, or complex shapes. CNC is better for strong, accurate, and functional parts. You choose based on the job, not just the machine.

Why is 3D printing not considered CNC?

Many think 3D printers are just a type of CNC machine. They are both controlled by G-code, and they follow a 3D model. But there’s a reason why experts don’t call 3D printers “CNC machines.”

3D printing is not CNC because it doesn't follow the subtractive manufacturing method, which is the core of CNC's definition.

What CNC really means

CNC stands for Computer Numerical Control. The term was created to describe machines like mills, lathes, and grinders. These machines all remove material. The common feature is subtractive action, not just computer control.

3D printers also use digital instructions. But they don’t subtract. They create something from scratch using additive layers. This breaks the traditional definition of CNC.

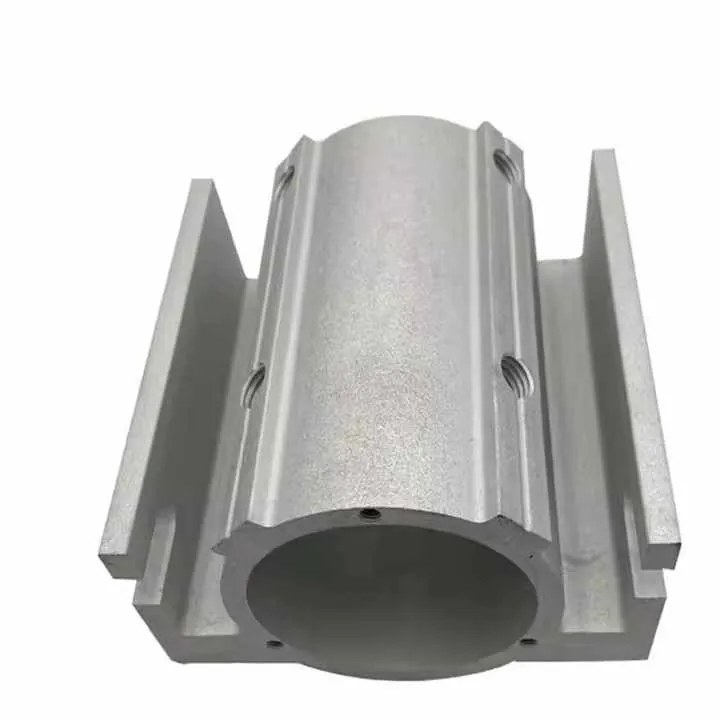

CNC machines = tools with cutters

A CNC mill spins a sharp tool to shave off material. A CNC lathe rotates a piece while a cutter shapes it. Every CNC tool starts with a solid and cuts it down.

3D printers push melted plastic, resin, or metal powder to create shapes. There’s no cutting or shaping. It’s a new form of manufacturing.

Control is not enough

Yes, both use motors, coordinates, and G-code. But CNC refers to how the material is shaped, not just how the machine is controlled.

| CNC Feature | Present in CNC Machines | Present in 3D Printers |

|---|---|---|

| Subtractive cutting | ✅ | ❌ |

| Spinning tools | ✅ | ❌ |

| Start with solid block | ✅ | ❌ |

| High-speed carving | ✅ | ❌ |

| Uses G-code | ✅ | ✅ |

| Computer controlled | ✅ | ✅ |

3D printers are computer-controlled tools. But without cutting tools, they fall outside the strict CNC category.

Which tasks are best for 3D printing vs. CNC?

Choosing the right tool depends on the task. Each method has its strengths. Using the wrong one can waste time, money, and materials.

Use 3D printing for complex, low-strength shapes. Use CNC for strong, accurate, and finished parts.

When to choose 3D printing

- Making early prototypes

- Testing shape, size, or fit

- Creating custom shapes with internal channels

- Making only one or two items

- Working with plastic or resin

Ideal 3D printing uses

| Use Case | Benefit of 3D Printing |

|---|---|

| Architectural models | Fast and cheap visual prototypes |

| Custom medical parts | Easy to personalize |

| Complex internal parts | Can’t be milled with cutters |

| Hobby models | Simple desktop machines |

When to choose CNC

- Making strong, working parts

- Using metal or hard plastic

- Needing tight tolerances

- Producing parts that will face stress or heat

- Requiring smooth surface finish

Ideal CNC uses

| Use Case | Why CNC is Better |

|---|---|

| Engine components | High strength and accuracy |

| Machine brackets | Tolerance and repeatability |

| Aerospace parts | Certified metals and finishes |

| Industrial tooling | Must resist wear and load |

In many cases, the two methods support each other. 3D printing helps with idea testing. CNC finishes the job for final production.

Where are both 3D printing and CNC used together?

More factories are combining 3D printing and CNC. This is not about replacing one with the other. It's about using both to speed up work and improve flexibility.

Factories use 3D printing to create prototypes or rough parts, then finish with CNC for accuracy, strength, and surface quality.

How hybrid workflows work

Some parts are 3D printed with metal powder, then milled to meet tight size and surface needs. Others are printed in plastic, tested, then cut in metal using CNC.

Examples of combined use

Aerospace

Designers 3D print complex support parts, then CNC trim edges for perfect fit. Some components are even 3D printed in titanium, then machined where bolts or seals go.

Automotive

Car companies print concept parts overnight. These get tested for shape and flow. If approved, the design moves to CNC for production.

Medical

Surgeons use 3D printed bone models for planning. Then, CNC machines cut titanium implants based on the plan.

Benefits of using both

| Step | 3D Printing Role | CNC Role |

|---|---|---|

| Step 1: Design Test | Print sample in plastic | — |

| Step 2: Fit Check | Easy to reprint | — |

| Step 3: Final Part | — | Cut from strong metal |

| Step 4: Finishing | — | Smooth, drill, and polish |

Combining the two methods brings the best of both: the creativity of 3D printing and the strength of CNC.

Conclusion

A 3D printer is not a CNC machine because it adds material, while CNC removes it. They follow the same digital logic but serve different tasks. Used together, they open new possibilities in modern manufacturing.