Leading my way through the maze of manufacturing delays, I felt the weight of deadlines growing. Could I really get the heatsinks on time?

In short: yes—but only if you understand how long a manufacturer takes, what influences that time, how to plan your order, and what trends are helping shorten it.

Let’s dive in together and figure out how to turn lead‑time uncertainty into a predictable advantage.

What lead times do heat sink manufacturers provide?

Hidden in the details of quoting you’ll find that heat‑sink manufacturers typically provide two tiers of lead time:

- For standard parts (existing tooling, common profiles) lead times may be as short as 15 to 20 days after sample approval and payment.

- For custom parts (new tooling, unique geometry, special finishes) lead times can stretch to 4 months or more, especially if full development is required.

Key numbers in a table

| Order type | Lead time range | Notes |

|---|---|---|

| Standard profile | 15–20 days | Standard sizes, existing tooling |

| Small custom batch | 7–15 days (CNC prototypes) | Quick machining services |

| Full custom build | Around 4 months (with tooling) | Includes prototype, test, tooling |

I once worked with a client who needed a custom extruded aluminium heat sink with special finish and dimensions. The full process—from drawings to delivery—took nearly 12 weeks. In contrast, another client used a standard model with minor CNC and got it within 3 weeks. That difference shows how lead times are directly tied to how custom your request is.

Why do lead times vary by design?

Every time I ask a manufacturer why one heat sink takes 3 weeks and another 3 months, they all say the same thing: it depends on the design. That answer makes sense when you break it down.

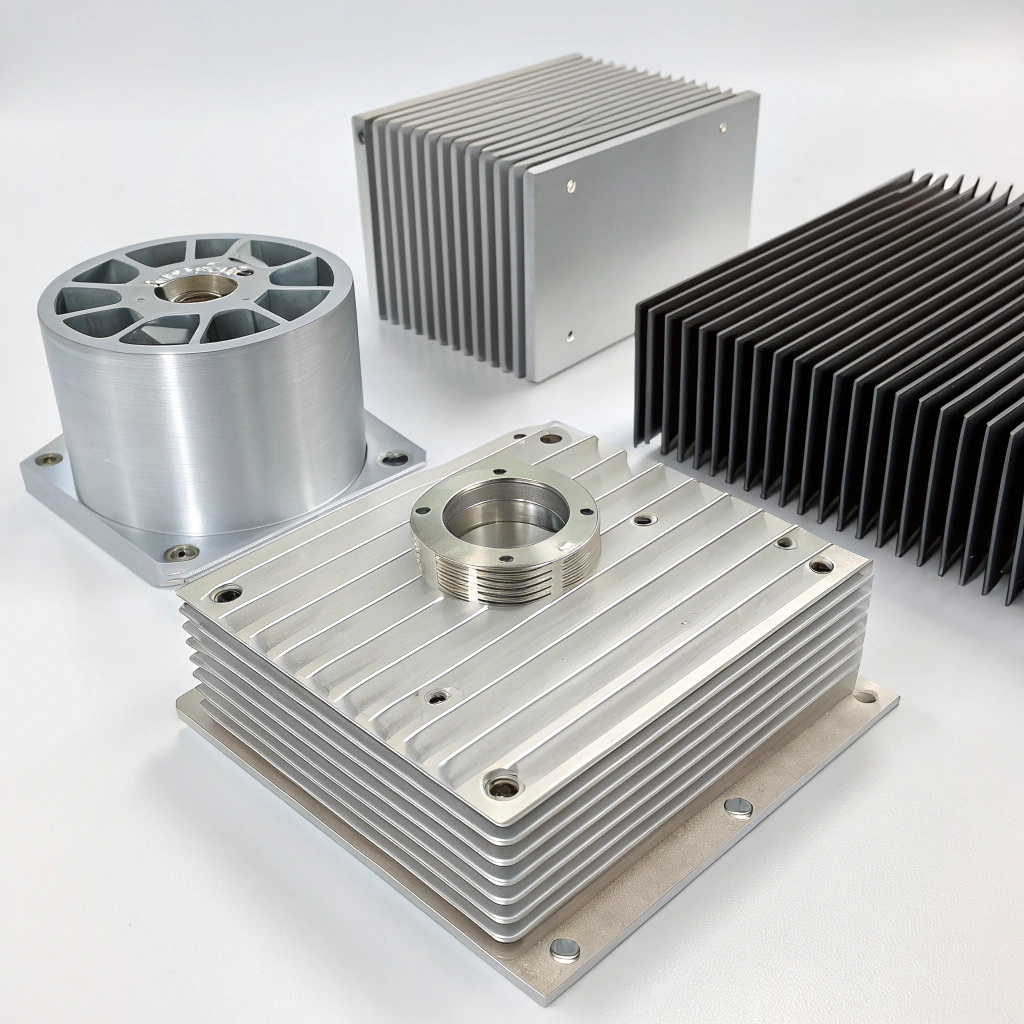

Design complexity, tooling, materials, volume, and finishing processes all shape the production timeline.

Common factors that add time

Tooling

If your heat sink design needs new extrusion dies, casting molds, or forging tools, that tooling needs to be designed, produced, and tested. This alone can take 4 to 6 weeks. If you're using machining or skiving processes without new tooling, you can save time.

Complex manufacturing

Bonded fins, integrated heat pipes, skived copper, and CNC-drilled profiles take longer than simple extrusions. More processes means more machines and more handling, and each step adds time.

Material choice

Aluminum is faster to process than copper. Special alloys may have longer lead times from raw material suppliers. If your part needs copper and also needs anodizing or coating, that adds more steps and more waiting.

Surface treatments

Anodizing, powder coating, and other finishes don’t just happen instantly. They require queue time, tank preparation, drying, and quality inspection. Some finishes may require external partners, which adds scheduling delays.

Order quantity

Larger orders sometimes move faster if they justify dedicated equipment. But small orders might wait longer in production queues, especially if the supplier is busy with higher priority jobs.

Design feedback loops

If your part requires a prototype, testing, or thermal validation, this can add weeks. Every design revision resets the clock. If you freeze the design late, you delay everything else.

Summary of delay causes

| Factor | Lead time impact |

|---|---|

| New tooling required | Adds 4–6 weeks |

| Complex geometry | Adds 1–2 weeks |

| Special material | Adds 1+ week (supply time) |

| Custom finish | Adds 5–10 days |

| Prototype + test | Adds 1–3 weeks per revision |

When someone asks me “Why does this take so long?” I ask them: how custom is your design? If it’s standard, quick. If it’s unique, expect to wait.

How to plan orders based on lead times?

Managing a project without considering lead times is like building a house without a blueprint. It’s a gamble. I always tell my clients: lead times should drive your order schedule, not the other way around.

To stay on track, you need to plan backward from your delivery date and build in every step: internal approvals, manufacturing time, shipping, and delays.

Steps I use to plan every order

- Define what product you need—standard or custom.

- Ask for formal lead time in writing from the manufacturer.

- Consider internal time—design finalization, approvals, PO issue.

- Add buffer time for revisions or communication delays.

- Don’t forget shipping—especially if you’re overseas.

- Consider placing repeat orders or blanket POs.

- Track key milestones: tool completion, test approval, production start.

- Always leave room for the unexpected.

Example schedule

You need parts by Week 20. The lead time is 12 weeks. Add 1 week for design freeze, 2 weeks for shipping and customs, and 2 weeks of safety buffer. That means you must place your order by Week 3 or 4 at the latest.

Table: Typical planning timeline

| Step | Time Needed |

|---|---|

| Design approval | 1–2 weeks |

| Tooling setup (if needed) | 4–6 weeks |

| Production and finishing | 4–6 weeks |

| Shipping & logistics | 1–2 weeks |

| Safety buffer | 1–2 weeks |

If your internal processes are slow, or the manufacturer has capacity issues, it’s smart to assume longer. I’ve had projects delayed because a one-day approval dragged into two weeks. Build in flexibility early.

What trends shorten production lead times?

The good news is that heat-sink production is getting faster. New methods, digital tools, and lean manufacturing are helping many factories reduce delays.

These trends can shave weeks off the standard timelines and help buyers get their parts sooner.

Five trends to know

1. Rapid prototyping

Soft tooling and CNC machining allow small batches or sample parts in as little as 7–10 working days. This reduces the trial-and-error cycle and helps confirm designs faster.

2. No-tooling options

Skived heatsinks and CNC-machined billets need no extrusion die. This skips the most time-consuming step for small batches.

3. Digital design & early feedback

More manufacturers use design-for-manufacturability checks and simulation early. This reduces errors and stops revisions before they slow you down.

4. Factory automation

Robotic loaders, night shifts, and digital tracking systems mean some plants can work 24/7. That improves production output and shortens lead time for committed orders.

5. Standardized components

Some suppliers now offer modular heat sinks or standard profiles that can be slightly modified. Using a standard base reduces tooling time and may allow instant shipping from stock.

How to benefit from these trends

- Choose suppliers who offer CNC, rapid tooling, or standard models.

- Use early-stage thermal simulation to confirm design before ordering.

- Opt for a production method that skips die-making if your order is small.

- Ask about partial shipments or phased delivery.

- Build supplier relationships to get priority in the queue.

When my clients follow these steps, they often get their products weeks earlier. The key is knowing what’s negotiable and what’s fixed in the lead-time equation.

Conclusion

Lead time from a heat sink manufacturer depends on the design, materials, tooling, and finish. Standard parts might ship in 2–3 weeks, while custom ones can take up to 4 months. By understanding these timelines, planning backward, and choosing suppliers who use modern, fast methods, you can meet your deadlines with confidence.