Products Details

| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Micro Machining or Not | Micro Machining |

| Product name | Aluminum Profile and Cnc Machining Service |

| Material | Aluminum |

| Surface treatment | Anodizing |

| Tolerance | +/- 0.01mm |

| Processing | CNC turning, CNC milling |

| Service | Customized OEM |

| Delivery Time | 10-20 Days |

| OEM/ODM | 100% |

| MOQ | 100 |

| Packing | Customers'requirements |

| Selling Units | Single item |

| Single package size | 10X10X10 cm |

| Single gross weight | 1.000 KG |

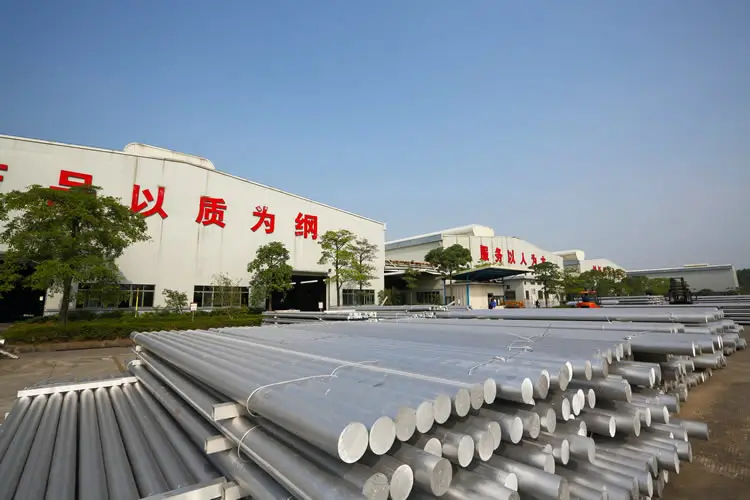

Our Manufacturing Base

Factory Panorama

Aluminum Bar Manufacturing Workshop

Mold Storage Warehouse

43 Aluminum Extrusion Lines (500-5500 Tons)

Powder Coating Workshop

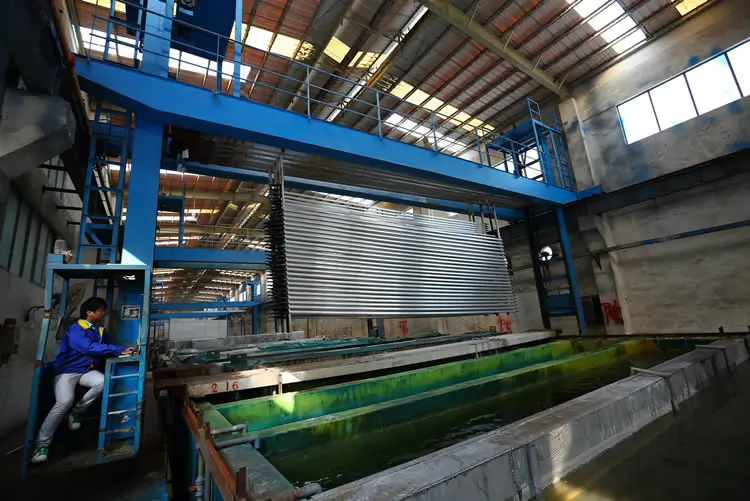

Anodizing Workshop

Deep Processing Workshop

CNC Precision Machining Workshop

Finished Product & Export Warehouse

FAQ

1.What are the benefits of aluminum lighting enclosures in production lines?

Aluminum lighting enclosures offer durability, heat dissipation, and corrosion resistance, making them ideal for continuous industrial use.