Products Details

Our Manufacturing Base

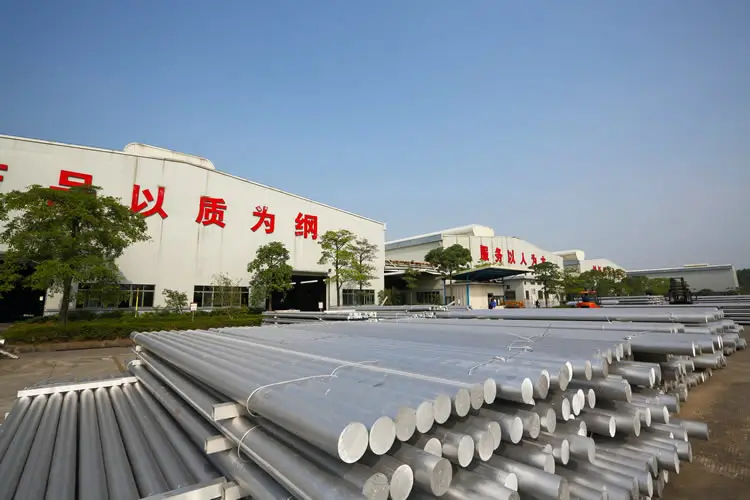

Factory Panorama

Aluminum Bar Manufacturing Workshop

Mold Storage Warehouse

43 Aluminum Extrusion Lines (500–5500 Tons)

Powder Coating Workshop

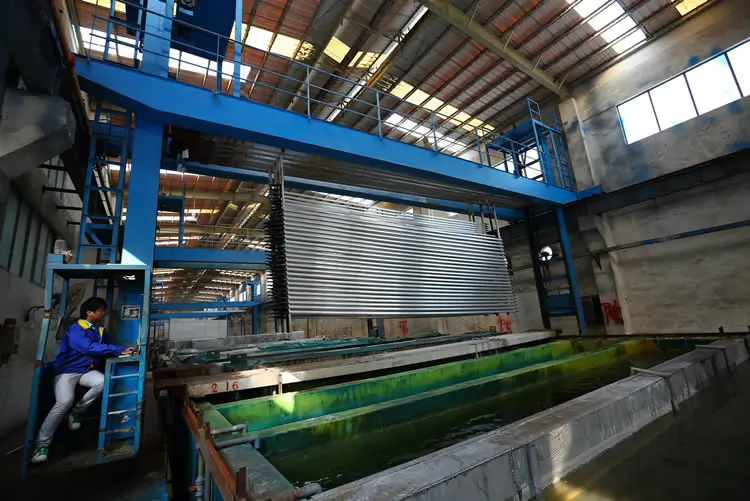

Anodizing Workshop

Deep Processing Workshop

CNC Precision Machining Workshop

Finished Product & Export Warehouse

FAQ

1. What are CNC Aluminum Heat Sink Parts?

They are components specifically designed for dissipating heat in electronic assemblies with CNC precision.

2. Can I order custom sizes of heat sinks?

Yes, we offer customizable options to fit specific assembly needs.

3. What is the main material used in these heat sinks?

They are made from high-quality aluminum for its excellent thermal properties.

4. Are these heat sinks suitable for high-power applications?

Absolutely, they are designed to handle high thermal loads efficiently.

5. How does CNC machining benefit heat sinks?

CNC machining ensures precise dimensions for optimal contact and heat transfer.

6. Is the surface finish of the heat sink important?

Yes, anodized finishes enhance corrosion resistance and thermal efficiency.

7. Can these heat sinks be used in automotive parts?

Yes, due to their durability and lightweight properties, they are suitable for automotive applications.