Products Details

| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Micro Machining or Not | Micro Machining |

| Product name | Aluminum Profile and Cnc Machining Service |

| Material | Aluminum |

| Surface treatment | Anodizing |

| Tolerance | +/- 0.01mm |

| Processing | CNC turning, CNC milling |

| Service | Customized OEM |

| Delivery Time | 10-20 Days |

| OEM/ODM | 100% |

| MOQ | 100 |

| Packing | Customers'requirements |

| Selling Units | Single item |

| Single package size | 10X10X10 cm |

| Single gross weight | 1.000 KG |

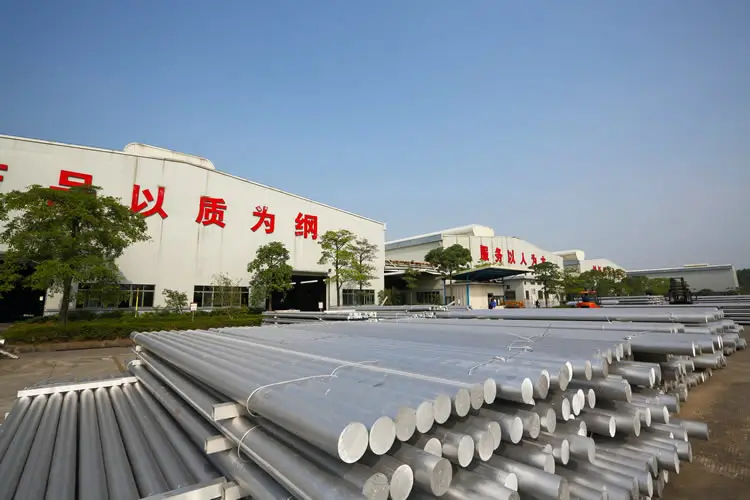

Our Manufacturing Base

Factory Panorama

Aluminum Bar Manufacturing Workshop

Mold Storage Warehouse

43 Aluminum Extrusion Lines (500-5500 Tons)

Powder Coating Workshop

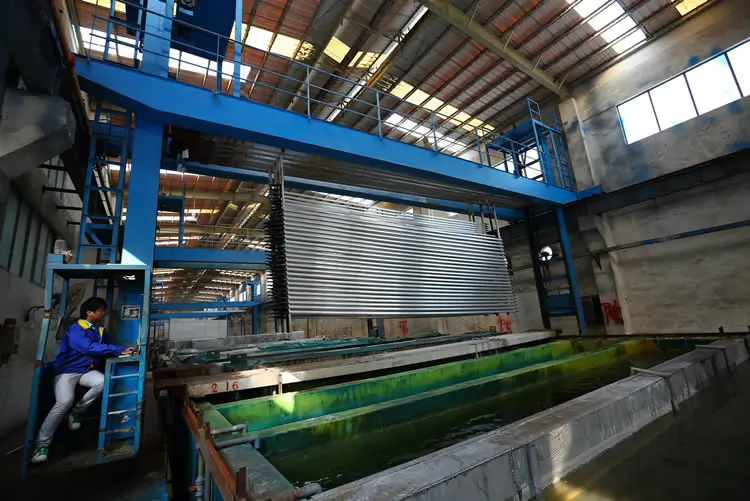

Anodizing Workshop

Deep Processing Workshop

CNC Precision Machining Workshop

Finished Product & Export Warehouse

FAQ

1.What are the advantages of a laser cut aluminum chassis?

Laser cut aluminum chassis offers high precision, smooth edges, and dimensional accuracy ideal for power controller housings.