Many people hear about CNC routers but don’t know what they really do. Some think they are only for woodworking, others confuse them with 3D printers.

CNC routers are automated cutting machines controlled by computer software, designed to precisely shape materials like wood, plastic, and metal.

Unlike manual tools, CNC routers reduce human error and allow for repeatable, high-accuracy production. This article explores how they work, why they matter, and where they shine.

How do CNC routers function in machining?

CNC routers can seem complex at first. They move fast, follow detailed patterns, and produce perfect shapes over and over again. That’s no accident.

A CNC router uses programmed instructions to move a spindle along three or more axes, cutting material with high precision.

The key to CNC routing is the CNC system—short for Computer Numerical Control. It takes a design file, usually created in CAD (Computer-Aided Design) software, and translates it into movement commands. These commands tell the router which direction to move, how fast to go, and how deep to cut.

The Process Breakdown

- Design: A technician or designer creates a digital blueprint.

- Programming: CAM (Computer-Aided Manufacturing) software converts the blueprint into G-code.

- Setup: The operator fixes the material on the table and selects the right cutting tool.

- Execution: The machine follows the G-code and begins cutting along the programmed paths.

CNC Router Axes

Most routers operate on three axes:

| Axis | Movement Type | Function |

|---|---|---|

| X | Left to Right | Horizontal movement |

| Y | Front to Back | Depth movement on the table |

| Z | Up and Down | Controls depth of the cut |

More advanced machines also include A, B, or C axes for rotation, ideal for complex 3D carving.

Common Materials Cut by CNC Routers

| Material | Applications |

|---|---|

| Wood | Furniture, cabinets, doors |

| Aluminum | Enclosures, signs, machine parts |

| Acrylic | Signage, displays, prototypes |

| MDF | Interior panels, decorative elements |

| Foam | Prototyping, molds, lightweight parts |

CNC routers eliminate guesswork. Once programmed correctly, they can run the same job 100 times with no variation. This is a major reason why manufacturers love them.

Why are CNC routers ideal for woodworking?

Traditional woodworking requires years of experience. Even then, achieving perfect cuts takes time and a lot of manual skill.

CNC routers simplify complex woodwork by delivering fast, clean, and consistent cuts with little manual labor.

In woodworking, shapes can be intricate—curves, grooves, joints. Doing this by hand is slow and often inconsistent. CNC routers take digital designs and cut them into wood with extreme precision.

Advantages in Woodworking

Speed and Efficiency

CNC routers can complete in minutes what might take hours by hand. This matters most for batch production or customized projects where speed is key.

Precision and Consistency

Each cut is accurate to fractions of a millimeter. This helps when making joints or patterns that must fit perfectly.

Less Waste

Since the router follows a digital plan, it reduces mistakes. That means fewer miscuts and less material waste.

Versatility

Woodworkers use CNC routers to:

- Cut out furniture components

- Engrave patterns or logos

- Drill clean holes

- Create custom moldings and trims

Many small woodworking shops use compact CNC routers for personalized projects. Large factories use full-sized routers to mass-produce furniture and panels.

CNC routers have made it possible to create highly detailed and complex wooden designs that were once too time-consuming or expensive to make by hand.

Which industries rely on CNC routers?

Many think CNC routers are just for wood shops or hobbyists. In reality, these machines are vital in multiple industries.

CNC routers are used in manufacturing, aerospace, signage, furniture, and many other sectors where precision and speed are required.

Major Industries That Use CNC Routers

1. Furniture Manufacturing

Furniture makers use CNC routers to cut wood, MDF, and plywood for frames, panels, and decorative parts. This speeds up production and ensures every piece is identical.

2. Signage and Advertising

Acrylic, plastic, and aluminum signs are often cut using CNC routers. Intricate letters, symbols, and logos can be cut out or engraved easily.

3. Aerospace

In aerospace, weight and accuracy are critical. CNC routers cut lightweight panels, plastic components, and composite materials for aircraft interiors.

4. Automotive

Custom dashboards, interior trim panels, and prototype parts are all created using CNC routers. They help designers test ideas quickly.

5. Marine

Boat interiors often include wooden cabinetry and panels. CNC routers produce these parts efficiently while maintaining a tight fit.

6. Construction

Architectural elements like decorative facades, panels, and staircases often start with CNC-routed components.

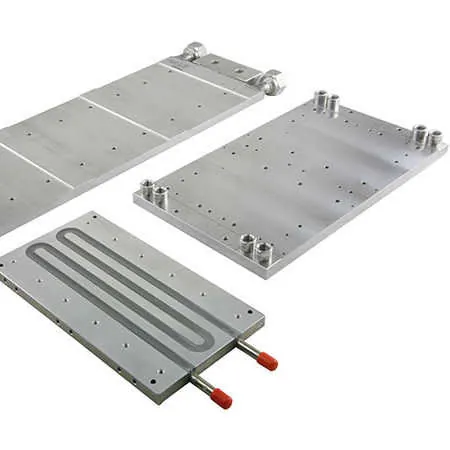

7. Electronics

Some components, like control panels or housing units, are cut from plastic or aluminum using routers.

Why They Rely on CNC

| Industry | Key Benefit |

|---|---|

| Furniture | Batch consistency and speed |

| Signage | Precision cutting of designs |

| Aerospace | Lightweight material cutting |

| Automotive | Rapid prototyping |

| Construction | Complex shapes at large scale |

| Electronics | Accuracy for enclosures |

These industries all depend on the speed, accuracy, and automation that CNC routers bring.

Where do CNC routers outperform other tools?

Some might ask—why not just use a laser cutter, plasma cutter, or manual router? What makes CNC routers better in certain situations?

CNC routers excel in versatility, safety, material range, and cost-effectiveness, especially for mid- to high-volume production.

Comparing CNC Routers to Other Tools

CNC Router vs Laser Cutter

- Laser cutters are great for engraving and cutting thin materials like acrylic or paper. But they struggle with thick wood and metal.

- CNC routers can cut through thicker materials and don’t risk burning or warping the material.

CNC Router vs Plasma Cutter

- Plasma cutters are excellent for thick metals but cannot handle wood or plastics.

- CNC routers cut a wider variety of materials, including aluminum and wood, without generating extreme heat.

CNC Router vs Manual Tools

- Manual tools depend on operator skill and can’t match the speed or accuracy of CNC.

- CNC routers offer repeatable precision, ideal for commercial and industrial use.

Performance Advantages

- Cost-efficiency: Once programmed, they save time and labor.

- Material flexibility: Cut wood, aluminum, foam, plastics.

- Low training needs: Operators don’t need deep manual skills—just software and machine basics.

- Safety: Reduced risk of injury compared to manual saws or drills.

When CNC Routers Are the Best Option

- Custom signage production

- Cabinetmaking and furniture design

- Lightweight metal part production

- Prototyping in product development

- Projects with repeatable patterns or cuts

If a job requires cutting different materials with high precision—especially in repeat runs—CNC routers often outperform all other tools.

Conclusion

CNC routers are more than just machines—they are essential tools across industries. From woodworking to aerospace, their ability to cut, shape, and engrave with accuracy makes them a smart investment for modern production.