Opening thought: CNC machines often seem the same, yet each type works in a special way to shape metal or plastic.

Different CNC machines use different methods to cut, shape or finish material. Each type brings unique tools and motions to meet different needs.

Let’s explore how they differ, why people pick each type, and where they shine in manufacturing.

How do various CNC machine types compare?

Small teaser: Not all CNC machines are equal. Some spin tools, some move cutting heads.

CNC machines vary by how they move and how the tool interacts with the material. This affects speed, precision, and how complex a shape they can make.

Overview of major CNC types

Many CNC systems fall into these broad categories:

| CNC Type | Main Action | Typical Use Case |

|---|---|---|

| CNC Milling | Rotating cutting head moves | Flat surfaces, pockets, holes |

| CNC Turning (Lathe) | Spinning workpiece, cutting tool moves | Round parts, shafts, threads |

| CNC Routing | Spinning router over material | Wood, plastic, light metals |

| CNC Laser Cutting | Focused laser beam cuts material | Sheet metal, plastics |

| CNC Plasma Cutting | Plasma torch cuts metal | Thick steel plates |

| CNC Waterjet Cutting | High-pressure water + abrasive | Heat-sensitive materials |

| CNC Grinding | Rotating grinding wheel removes material | High-precision surfaces |

| CNC EDM / Wire EDM | Electrical sparks etch material | Hard metals, complex shapes |

Compare their strengths and weaknesses

- Milling and turning offer high precision. They suit most metal parts.

- Laser, plasma, and waterjet excel at cutting shapes from sheets. They do not carve solid blocks easily.

- EDM and grinding deliver great precision for hard metals or fine finishes.

- Routing is best for soft materials like wood or plastic; not ideal for hardened steel.

How precision, cost, and speed shift across types

CNC milling and turning often balance precision and cost. Laser and plasma cut quickly, but give moderate precision compared to milling. Grinding and EDM slow parts removal but reach tight tolerances. Waterjet works slowly but avoids heat buildup. The choice depends on what matters: speed, detail, material, or cost.

In short: each CNC type compares by what it does, how precise it is, how fast, and what material it suits. That comparison helps pick the right machine for a job.

Why do industries choose different CNC categories?

Opening push: One company values speed. Another values precision. They choose different CNC machines accordingly.

Industries pick CNC categories based on material type, part design, required tolerance, and production volume. Each CNC type suits certain trade‑offs.

What drives the choice of CNC type

Several factors influence selection:

- Material type and thickness: Soft plastic, wood, thin metal sheets, or heavy steel blocks.

- Part geometry: Flat parts, cylindrical rods, hollow shapes, or complex curves.

- Precision required: For structural use, cosmetic surfaces, or tight mechanical fit.

- Speed and volume: Single custom parts or mass production.

- Cost and waste: Amount of scrap material and machine operating cost.

Examples from different industries

For example, furniture makers often use CNC routing. They cut wood or MDF to shape for chairs or cabinets. This gives fast cutting at low cost.

A factory building metal frames for solar panels might use CNC milling or extrusion-based CNC to shape aluminum. They need straight edges and precision drilling for assembly.

A shipyard might use plasma cutting or waterjet for thick steel plates. Speed and ability to cut big plates matter more than fine detail.

A tool maker building hard tooling or moulds may use grinding or EDM. They need fine detail and precise contours on hardened steel.

Trade-offs: cost vs. precision vs. versatility

No single CNC type is best in all cases. If precision and finish matter, milling or EDM is better. If shape and speed matter, plasma or laser shine. If material is soft and cheap, routing wins. Thus industries choose based on what matters most for their parts.

Summary of decision factors

| Factor | Influences Which CNC Type |

|---|---|

| Material hardness | Milling, EDM, Grinding for hard metals |

| Sheet vs. block stock | Laser, Plasma, Waterjet for sheets; Milling/Lathing for blocks |

| Required tolerance | Tight → Grinding/EDM; Moderate → Milling/Turning |

| Production volume | High volume → Faster cutting (Laser/Plasma); Low volume or custom → Milling/EDM |

| Cost & waste limit | Low cost → Routing or simple cutting; High precision → Milling/EDM even with higher cost |

Because industries vary in priorities, they pick CNC categories differently. That gives flexibility across all manufacturing types.

Which CNC types suit complex machining?

Quick hook: Some parts look simple. Some are curves and holes in 3D. Complex parts require smarter machines.

For complex shapes and high precision, CNC milling, 5‑axis CNC, EDM or grinding often deliver the needed control and accuracy.

What is complex machining

Complex machining means parts with tight curves, multiple angled faces, internal pockets, holes at odd angles, fine surface finishes, or high dimensional accuracy. Examples: engine blocks, aerospace components, medical implants, custom tools.

CNC options for complex parts

Often used CNC machines for complex jobs:

- Multi‑axis CNC Milling (3, 4, or 5 axis)

- CNC EDM / Wire EDM

- CNC Grinding

- CNC Turning with live tooling (for parts mixing cylindrical and flat features)

Why multi-axis CNC milling helps

With multi-axis milling, cutting head moves along several axes. Workpiece can rotate or tilt. Tool can approach surfaces from angles. This allows cutting complicated shapes in fewer setups. It saves time and ensures precision.

Why EDM and grinding are useful

EDM uses controlled electrical discharges to remove material. It is ideal for hard metals and complex internal shapes. It also avoids physical cutting forces that might deform the part.

Grinding removes material slowly but with high precision. It gives good surface finish and exact dimensions. It is good for final finishing or tight tolerance areas.

Example scenario: aerospace part

For example, an aerospace bracket might have internal cooling channels, angled mounting surfaces, and thin walls. Multi‑axis milling can rough out the shape. Then EDM shapes internal channels. Finally grinding polishes sealing surfaces.

Combination of CNC types gives flexibility. Each machine does what it does best. In this way, even complex parts become easier to produce consistently.

When routing, laser, or plasma fail for complexity

Routing or plasma cutting is good for flat shapes. They cannot shape 3D curves or internal pockets in solid material. Laser and waterjet cut only 2‑D outlines on sheets. They cannot manage angled surfaces, curves, or internal cavities. Thus they are not suited for complex machining of bulk material.

Conclusion on complex machining

For complex, high‑precision parts, combining multi‑axis milling, EDM, and grinding gives the best result. These CNC types deliver fine control, accuracy, and ability to handle hard materials.

Where are specific CNC machine types used?

Curious start: You might find one CNC in a wood shop, another in a heavy‑duty steel plant. Each setting demands a different machine.

Each CNC type finds its place in industries where its strengths match material, volume, and precision needs.

Common industries and CNC usage

Different industries rely on certain CNC types:

- Furniture and cabinetry: Use CNC routing for wood and MDF.

- Metal fabrication shops: Use laser, plasma, or waterjet for sheet cutting; CNC milling or turning for metal parts.

- Automotive and aerospace: Use 5‑axis milling, EDM, and grinding for engine parts, structural components, and molds.

- Tool and die shops: Use EDM and grinding for molds, dies, and tooling plates.

- Signage and advertising: Use CNC routing, laser cutting, or waterjet for signs from plastic, wood, acrylic, or light metal sheets.

- Construction industry: Use CNC plasma or laser for steel beams and plates; milling for custom metal connectors.

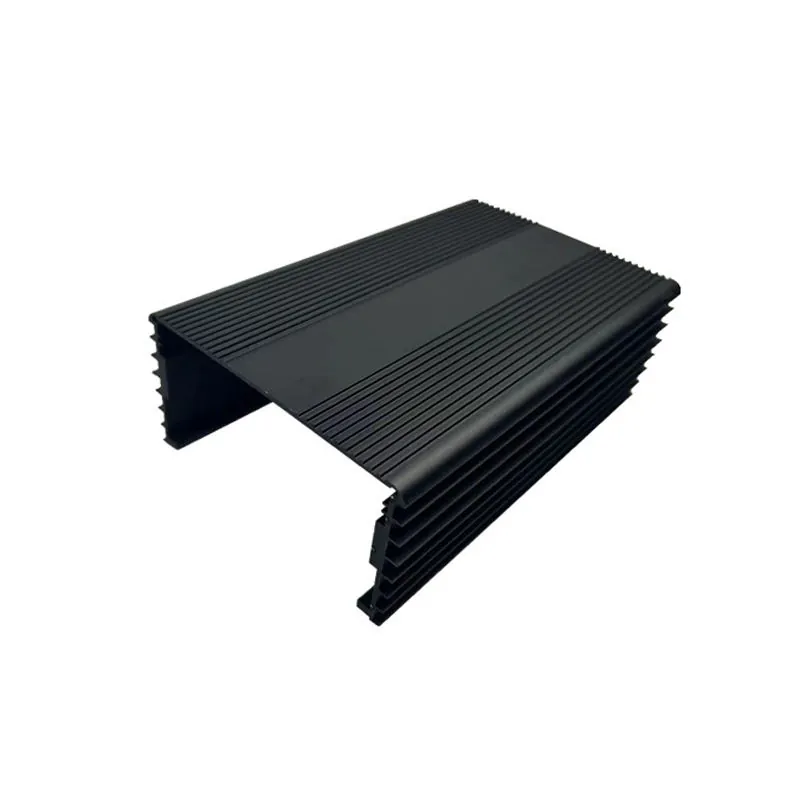

- Electronics enclosures and heat sinks: Use CNC milling for aluminum extrusions and housing parts.

Example: furniture shop vs. aerospace parts supplier

A small furniture shop may own only a CNC router. It cuts boards, carves cabinetry panels, and shapes decorative pieces. The focus is fast cutting of soft material.

An aerospace parts supplier needs parts with tight tolerance and complex shape. They may use 5‑axis milling, EDM, and CNC grinding. The machines may run for hours per part. The focus is precision, reliability, surface finish, and material strength.

Table: CNC type vs. Typical Industries

| CNC Type | Industries / Settings | Why It Works There |

|---|---|---|

| CNC Routing | Woodworking, signage, cabinetry | Cuts wood/plastic fast and clean |

| CNC Laser Cutting | Sheet metal shops, signage, prototyping | Fast, precise sheet cutting |

| CNC Plasma Cutting | Steel fabrication, construction | Cuts thick metal fast |

| CNC Waterjet Cutting | Glass, stone, metal sheets, composites | Cuts materials sensitive to heat |

| CNC Milling / Turning | Automotive, electronics, general parts | Shapes complex parts from solid blocks |

| CNC EDM / Grinding | Tool & die shops, aerospace, molds | High-precision, hard-metal machining |

Factors shaping CNC usage per sector

Industries choose CNC types based on:

- Material type: Wood → routing; metal → milling/turning or cutting.

- Part complexity: Flat parts → cutting; 3D complex parts → milling/EDM.

- Finish quality: For shiny or exact finish → grinding or EDM.

- Production volume: High-volume sheet cutting → laser or plasma; low-volume custom parts → milling/EDM.

- Cost and waste concerns: Sheet cutting wastes minimal material; block machining wastes more but gives stronger parts.

Observations across global manufacturing

In many factories worldwide, lightweight aluminum frames (for windows, solar panels, or housings) use CNC milling after extrusion. Stainless steel structures for buildings get plasma or laser cuts. Custom machinery parts get turned and milled. Hard tooling and molds use EDM.

Different CNC types coexist. A single factory may have multiple machines. The mix depends on its product line. This flexibility helps manufacturers meet varied demands.

Conclusion

Different CNC machines serve different needs. Some excel in speed and volume. Some give fine detail and strong parts. The right type depends on material, design, precision, and cost. Understanding the differences helps pick the best machine for each job.