Choosing the wrong metal for a demanding job is like using a plastic knife to cut steel — it simply won’t work.

The strongest metals include tungsten, titanium, and chromium. Strength varies by type: tensile strength, yield strength, and hardness all measure different aspects of performance.

Engineers must go beyond just "strong" or "weak." The right metal depends on how it’s loaded, shaped, and used.

How Does Alloy Composition Affect Metal Strength?

Sometimes a tiny addition — even 1% — changes a metal from brittle to bulletproof. Yet, not everyone realizes how powerful alloying can be.

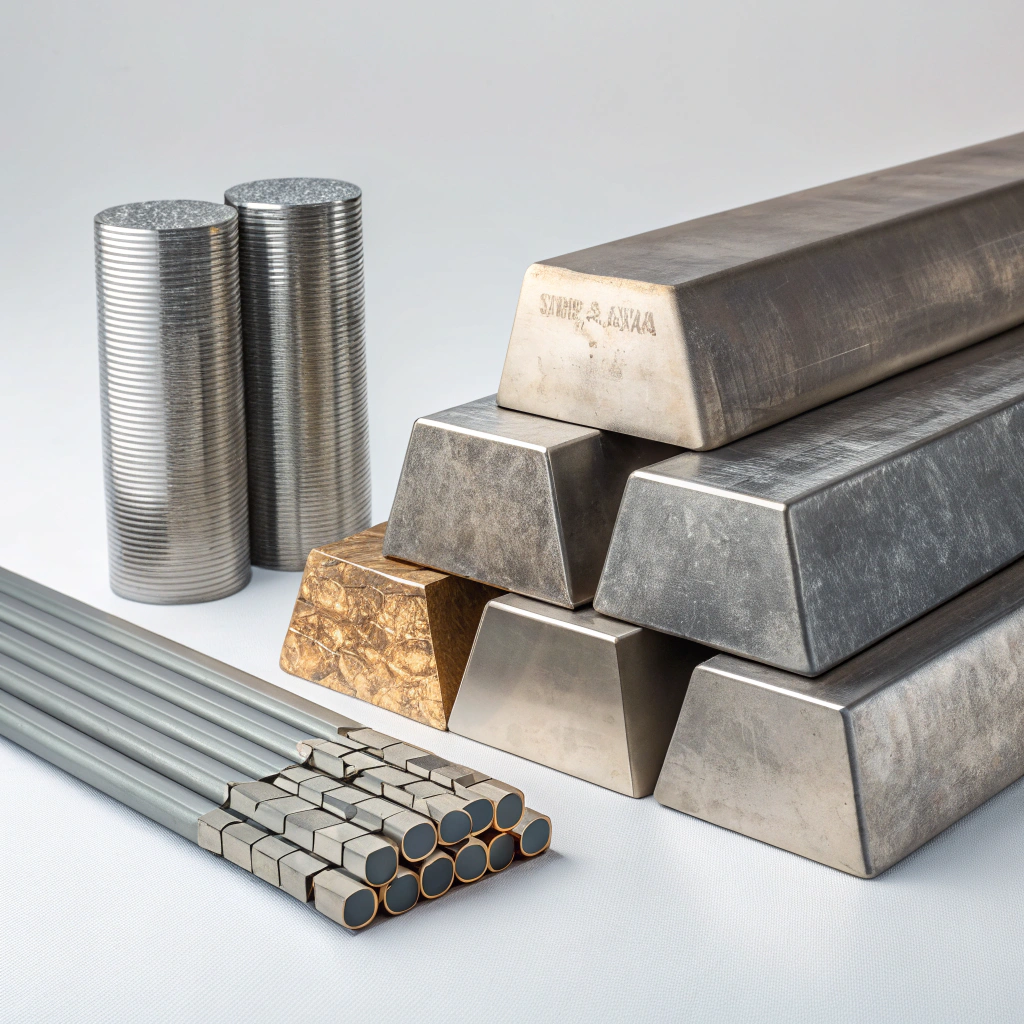

Alloy composition directly influences strength by altering the metal’s internal structure. Additives like carbon, chromium, or vanadium improve tensile strength, toughness, and hardness.

What Is an Alloy?

An alloy is a mix of a base metal and one or more other elements. Most metals in real-world use aren’t pure. For example, steel is an alloy of iron and carbon.

How Alloying Increases Strength

Adding atoms of different sizes disrupts the base metal’s crystal structure. That makes it harder for the layers of atoms to slide, which increases strength.

Here’s a basic table comparing a few common alloys and what elements make them stronger:

| Alloy Name | Base Metal | Key Additives | Strength Impact |

|---|---|---|---|

| Stainless Steel | Iron | Chromium, Nickel | Corrosion resistance, strength |

| High-Speed Steel | Iron | Tungsten, Molybdenum | Maintains strength at high heat |

| 7075 Aluminum | Aluminum | Zinc, Magnesium | High strength, light weight |

| Titanium Alloy | Titanium | Aluminum, Vanadium | High strength-to-weight ratio |

Grain Refinement and Heat Treatment

Alloying is only the start. Heat treatment techniques like quenching, tempering, and annealing allow engineers to refine grain size and further strengthen metals. Smaller grains, more boundaries, and less movement mean tougher metals.

What Are the Industrial Uses of High-Strength Metals?

Strong metals cost more. So why use them at all? Simple — in many industries, failure is not an option.

High-strength metals are used in aerospace, automotive, construction, and defense industries where performance, safety, and weight reduction matter most.

Aerospace

Aircraft and spacecraft must be light and strong. Titanium alloys are widely used in jet engines and airframes. They resist heat and fatigue while saving weight.

Automotive

In high-performance vehicles, steel alloys with high tensile strength help reduce weight without compromising safety. Cars now use advanced high-strength steel (AHSS) in their safety cages.

Construction

Skyscrapers, bridges, and tunnels use high-strength low-alloy steel (HSLA) for structural elements. These materials resist weather and carry massive loads.

Oil and Gas

Drill bits, pipelines, and valves often use alloys like Inconel and Hastelloy. These survive extreme pressure, temperature, and corrosion deep underground or underwater.

Here’s a summary table of typical applications:

| Industry | Common Metals Used | Key Requirements |

|---|---|---|

| Aerospace | Titanium, Inconel | Strength, heat resistance, low weight |

| Automotive | AHSS, Aluminum Alloys | Crash resistance, fuel efficiency |

| Construction | HSLA, Structural Steel | Load-bearing capacity, weathering |

| Medical | Titanium, Stainless Steel | Biocompatibility, strength |

| Energy | Inconel, Hastelloy | Corrosion, pressure, high temperature |

How to Select the Right Metal for Engineering Projects?

Selecting a metal seems easy — until something fails. The wrong choice leads to fractures, recalls, and lost business.

To choose the right metal, assess the project’s strength requirements, environment, weight limits, budget, and manufacturability. Use mechanical data, corrosion ratings, and fabrication properties.

Step 1: Define the Application

Is the metal for a frame, a fastener, a rotating shaft, or a decorative panel? Each task has different needs. Consider:

- Will it carry weight?

- Does it face impact or vibration?

- Will it be outdoors, near saltwater, or in heat?

Step 2: Identify Key Properties

Pick the most important factors. These usually include:

- Tensile Strength – How much it can stretch before breaking

- Yield Strength – How much force causes permanent deformation

- Hardness – How well it resists dents and scratches

- Corrosion Resistance – Whether it rusts or degrades in moisture

- Machinability – Whether you can cut, weld, or form it easily

Step 3: Match the Budget

Sometimes the best metal isn’t affordable for your project. Titanium is great — but at $20/kg, it’s not for every job. Choose materials that meet your specs without overspending.

Step 4: Check Certifications and Standards

Make sure the metal meets local or international codes. Look for ASTM, ISO, or EN standards to ensure quality and traceability.

What Future Metals Are Expected to Be Stronger?

Science keeps pushing boundaries. What’s impossible today may be standard tomorrow.

New high-entropy alloys, graphene composites, and advanced ceramics are set to surpass today’s strongest metals in strength, toughness, and temperature resistance.

High-Entropy Alloys (HEAs)

These are made by mixing five or more metals in equal amounts. The random atomic structure makes them super strong, corrosion-resistant, and stable at high temperatures.

Researchers have found some HEAs that outperform stainless steel in both strength and ductility.

Graphene-Reinforced Metals

Graphene is stronger than any known material. When mixed into metals like aluminum or copper, it dramatically improves strength without adding much weight.

These materials are still expensive to make, but prices are dropping as methods improve.

Metallic Glass

Unlike regular metals, metallic glass lacks crystal structure. This gives it incredible hardness and elasticity. It’s used in high-end electronics and watch parts but could expand to aerospace or tools.

Nanostructured Metals

By refining grains down to the nanometer level, scientists make metals that are much stronger than their regular forms. The challenge is scaling production and keeping costs down.

Conclusion

Knowing which metal is strongest isn’t enough. You need to know which metal is strongest for your purpose. That means understanding alloys, testing, environments, and new innovations. Only then can you choose the right metal with confidence.